46

SITE REPORT

LIFTING

ACT

SEPTEMBER 2013

Citadel Contractors’ LR 1300 lifted and installed the world’s widest Tilt-Up wall panel.

I

t’s not every day that a crane makes a

world record-setting lift, but that is just

what happened in Rock Hill, SC. The

crane involved was a Liebherr LR 1300

owned by Citadel Contractors, Inc., and

the project was the construction of York

Preparatory Academy High School.

Citadel’s LR 1300 lifted and installed the

largest Tilt-Up panel on record, according

to Citadel Vice President Jason Swagert.

“This particular wall section was

designed with several openings, making

it hard to find a place to add a joint,” he

explains. “Our idea was to pour an 89-foot

wide panel with multiple openings.

We created a model; we made up little

Critical rigging gear

This particular Tilt-Up panel was designed

with nine vertical openings. Using a

38-foot spreader bar, the wall was lifted up

from 16 pick points designed into the face

of the wall system. Four crewmen on the

ground held onto ropes at each pick point,

slowly guiding the panel and keeping it

level as the crane operator slowly lifted

it into position. The lift required expert

riggers and signal persons as well as an

experienced Tilt-Up crane operator,

according to Swagert.

“Fortunately, we had all of the necessary

rigging and lifting gear,” says Swagert. “If

we did not already have it, it could have

made this lift cost prohibitive. This was

the fourth building on the campus

of YPA. The other three buildings

were built last year and school was

in session so the buildings were

occupied. Certain parts of the site

were flagged off to keep students

(and parents) at a safe viewing

distance.”

Wolfgang Herzog, vice president

sales, Southeast and Caribbean

Liebherr Nenzing Crane Co., was

on the Citadel jobsite the day of

the lift.

“Being there and witnessing the

excitement and joy of everyone

involved about this perfectly

executed lift was a very unique

experience,” he says. “We at

Liebherr are proud that the LR

1300 gave Citadel the possibility to

archive this world record lift.”

Quick construction

Among the main advantages of

Tilt-Up construction is the ability to frame

a building quickly. Tilt-Up construction

is also very cost effective, Swagert says.

Additional advantages are durability,

thermal economy and design versatility as

evidenced by this uninterrupted 89-foot

wide Tilt-Up panel.

Swagert says the 330-ton capacity

Liebherr LR 1300 was the perfect crane

for this project. The crane offered the

productivity required and also offers quick

and easy transport and assembly, he adds.

Tilt-Up record

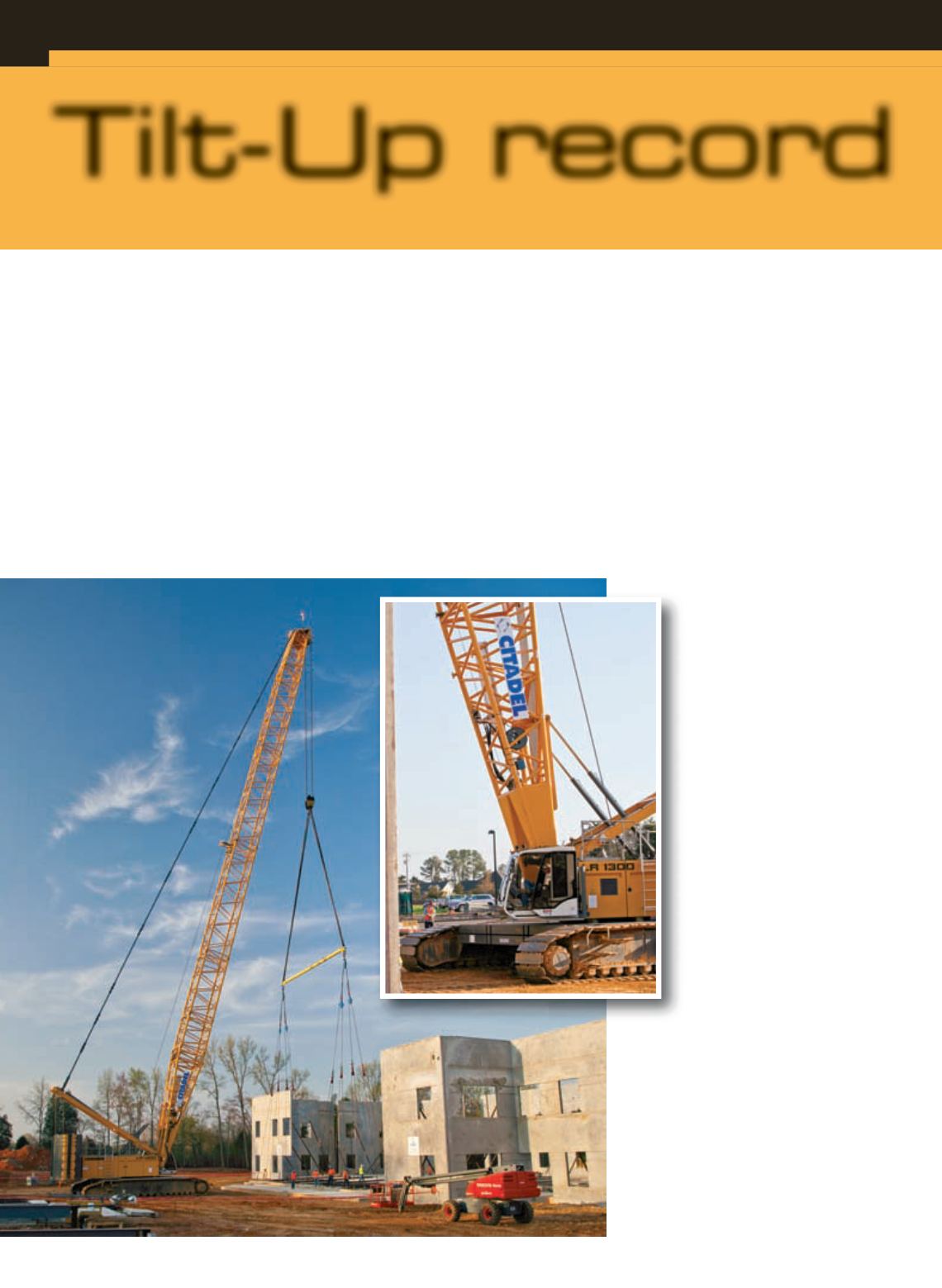

Using a 38-foot spreader bar,

the wall was lifted up from 16

pick points designed into the

face of the wall system.

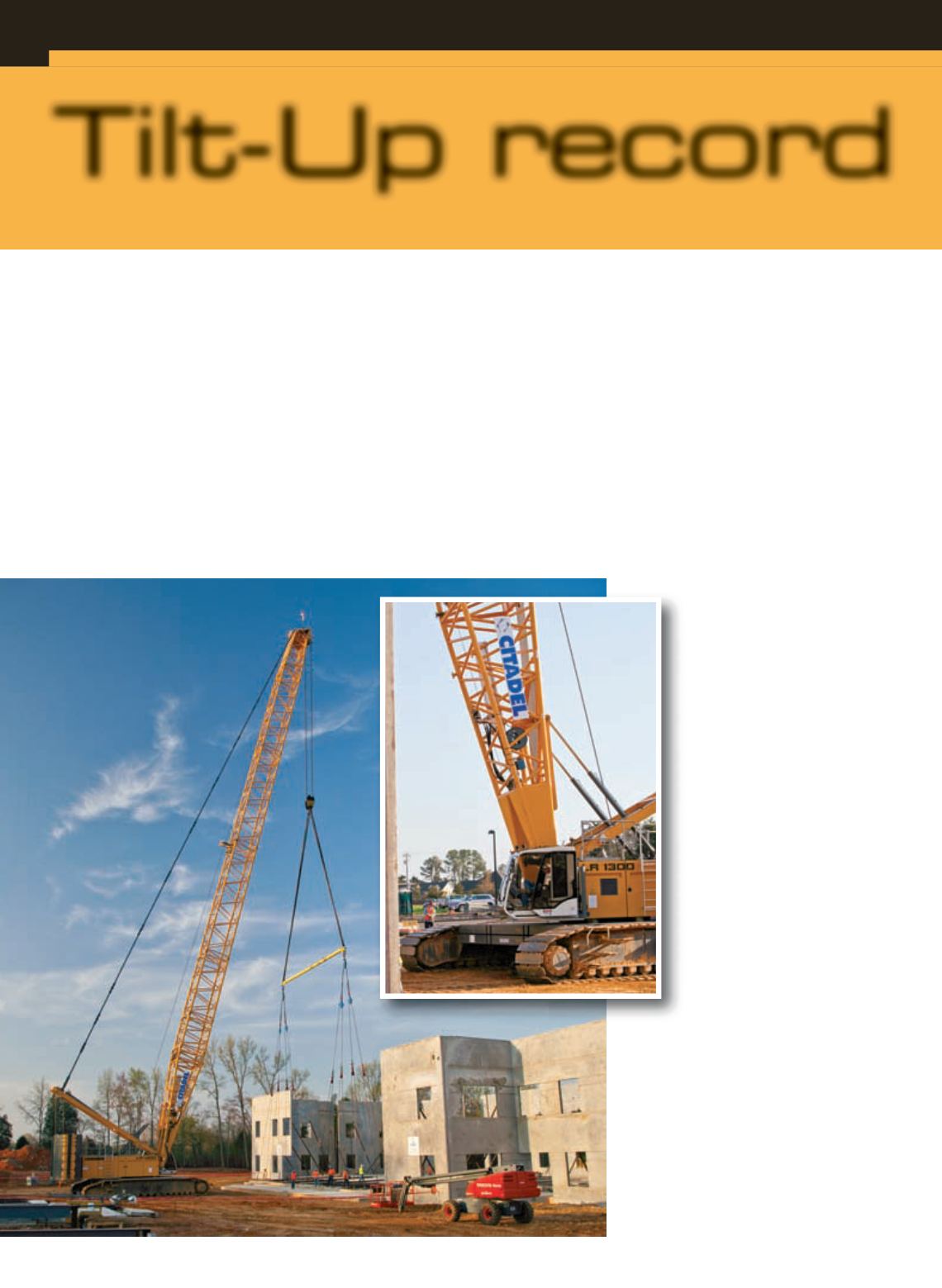

INSET: Tilt-Up work requires

careful planning and a high-

performance crane, such as

the Liebherr LR 1300.

miniature panels and positioned the

panels on the slab the way they should be

poured.”

While the lift did not test the capacity

of the LR 1300, the rigging plan required

careful execution. The huge Tilt-Up panel

measured approximately 89-feet wide by

30-feet tall and weighed about 130,000

pounds. Typical panels on the project

measured 25-feet wide and 30-feet tall.

Citadel, which has been performing

Tilt-Up work for more than 15 years,

specializes in this type of construction.

The company has lifted and set into place

larger than normal Tilt-Up panels, but the

one in Rock Hill, SC was the widest.