29

september 2013

international

construction

HIGH RISE

The rise of the super skyscraper

Rental growth in Hong Kong

New crane for high-rise projects

>

D

emand for cranes in the rental market in Hong Kong, China, is booming,

according to Manitowoc the owner of the Grove brand. It reports that there is a

shortage of operators and rental rates are increasing by +10% every year.

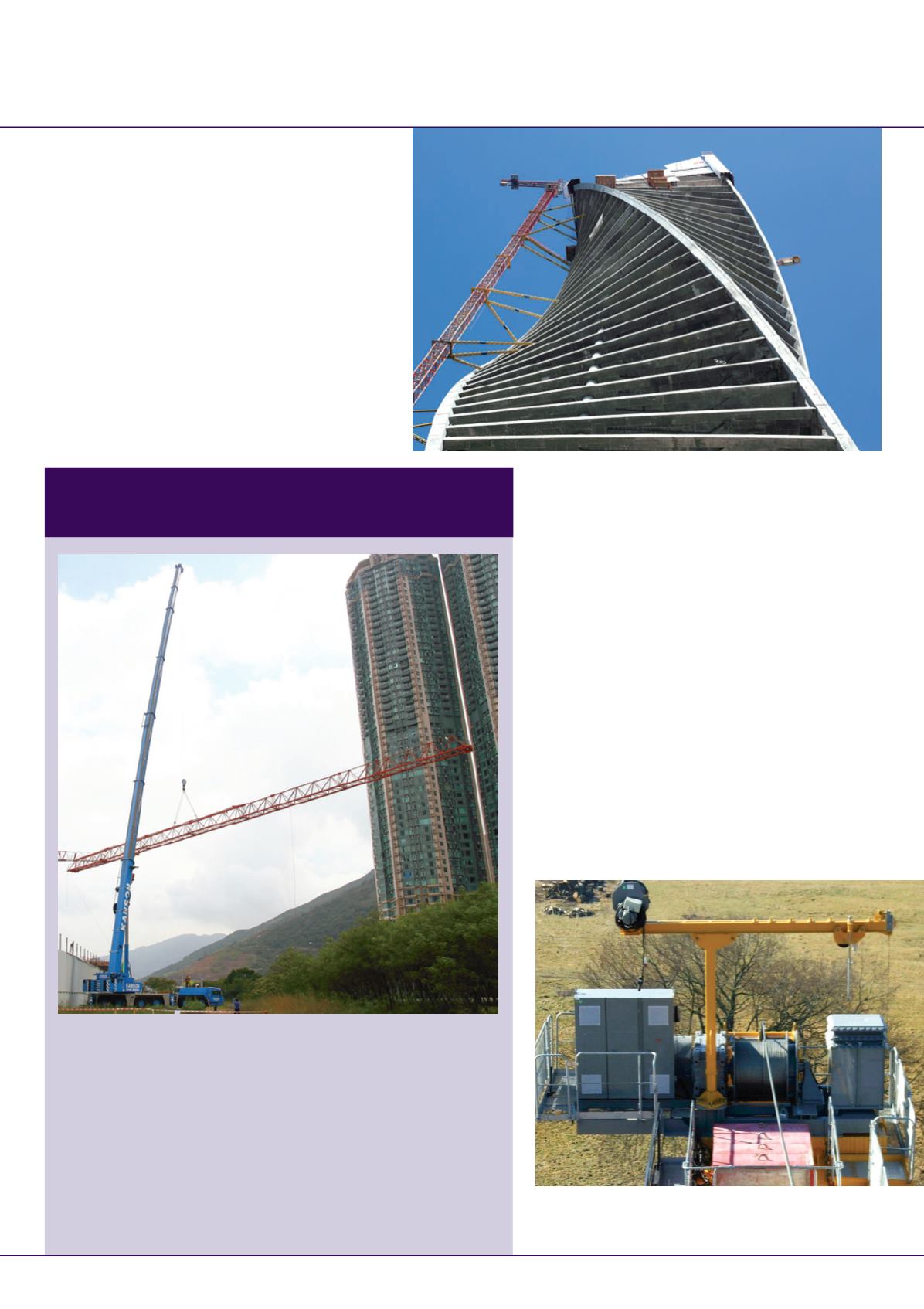

Local rental company Kanson Crane & Heavy Transport bought a Grove GMK6300L all-

terrain crane to help with tower crane assembly and high-rise construction jobs.

The new 300 tonne capacity model added to Kanson’s 50-strong fleet and filled a gap

in the company’s portfolio, according to company founder Nelson Kan.

“The Grove GMK6300L has a long boom perfect for tower crane erection. We also have

considerable work to do on high-rise structures as well as replacement of old buildings

in Hong Kong. The 6300L will be the ideal solution for all these applications.”

The crane has a seven-section, 80 m boom is the longest in its class, designed for

challenging lifts without the need to rig the jib.

up to 225 m/min, making it the first to break the 200 m/min

barrier, according to the company. The latest new winch to be

introduced is the 270 LVF, a 200 kW-rated unit which can

handle loads of up to 40 tonnes in four falls at a maximum

speed of 162 m/min.

Collaboration

Keeping to tight schedules and avoiding potentially costly

project overruns are key challenges on high-rise developments.

Manufacturers are demonstrating that they are prepared to work

closely with contractors to make sure the right tools for the job

are on site at the right phase in construction.

The fabrication of concrete elements plays a central role in the

construction of most skyscrapers, and formwork companies are

constantly working to improve the efficiency with which the

core and floor slabs of a building can be put in place.

Peri, for instance, is working with contractor CJSCRenaissance

Construction to ensure that the Evolution Tower, a new high-

rise landmark in Moscow, Russia, gains 4.3 m in height each

week during the peak of construction.

The tower will be 249 m when complete in 2014, and form

an iconic part of Moscow City – a new business district. Each

floor of the tower twists 3

o

in relation to the preceding one,

arranged around the central core of the building, making the

entire structure twist clockwise from its base by more than 150

o

.

Peri engineers developed a crane-independent formwork

system on the basis of its RCS and ACS self-climbing ranges. The

ACS system was used with Peri’s Vario GT 24 wall formwork

for the building core, while customised Uniportal slab tables

were used to form the floor slabs and a diagonally climbed RCS

climbing protection panel and landing platform accompanied

every phase.

Core walls and floor slabs were concreted in one pour, with

each floor divided into three concreting sections. Peri said the

special feature of its solution for the Evolution Tower was the

combined climbing formwork for the vertical core walls and

Potain’s latest winch is the 270 LVF, a 200 kW machine

that can handle loads of up to 40 tonnes in four falls at a

maximum speed of 162 m/min.

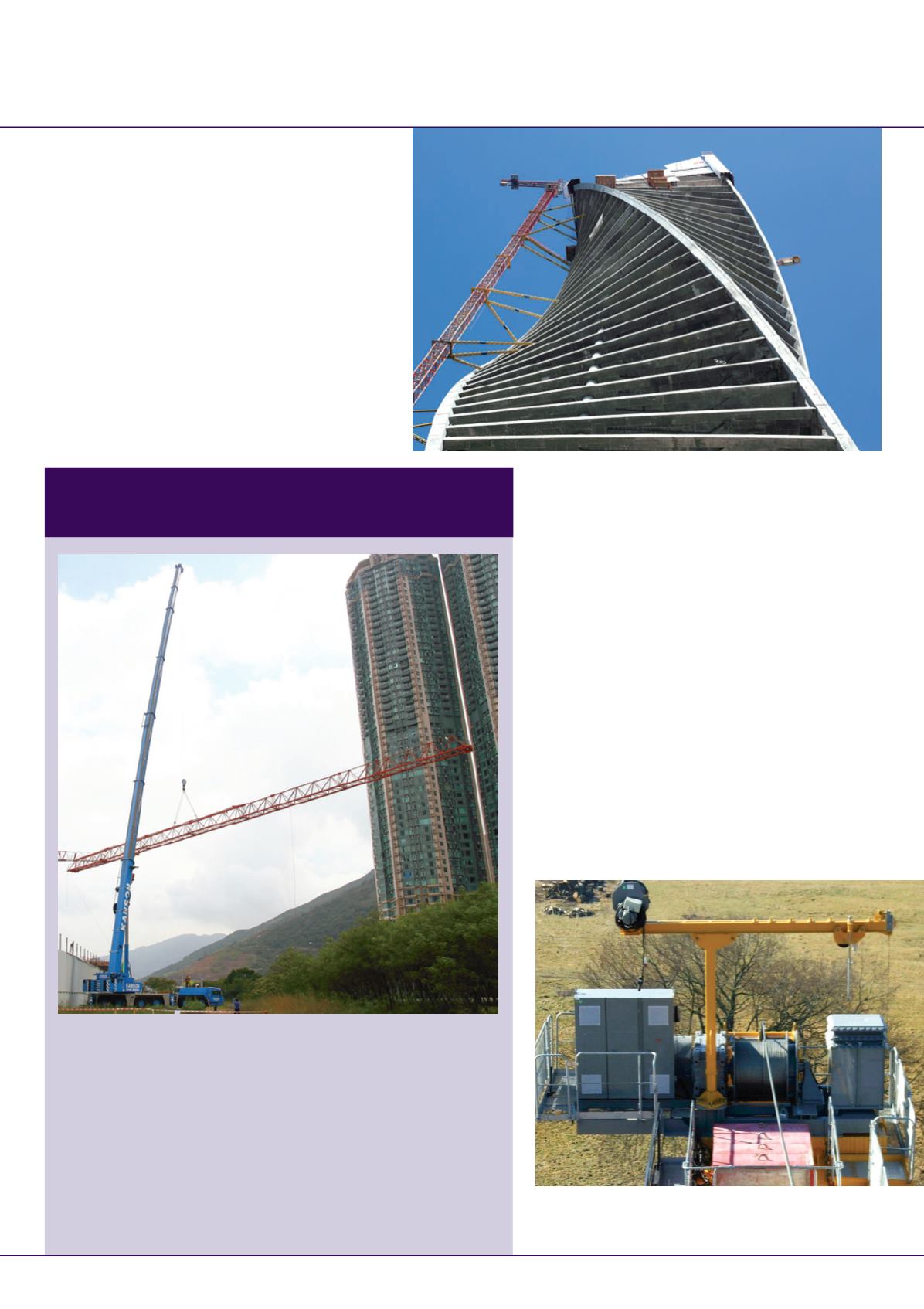

Peri developed a crane-independent formwork concept for

contractor CJSC Renaissance to support construction of the

249 m Evolution Tower in Moscow, Russia.