41

IN ACTION

d

&

ri

NOVEMBER-DECEMBER 2013

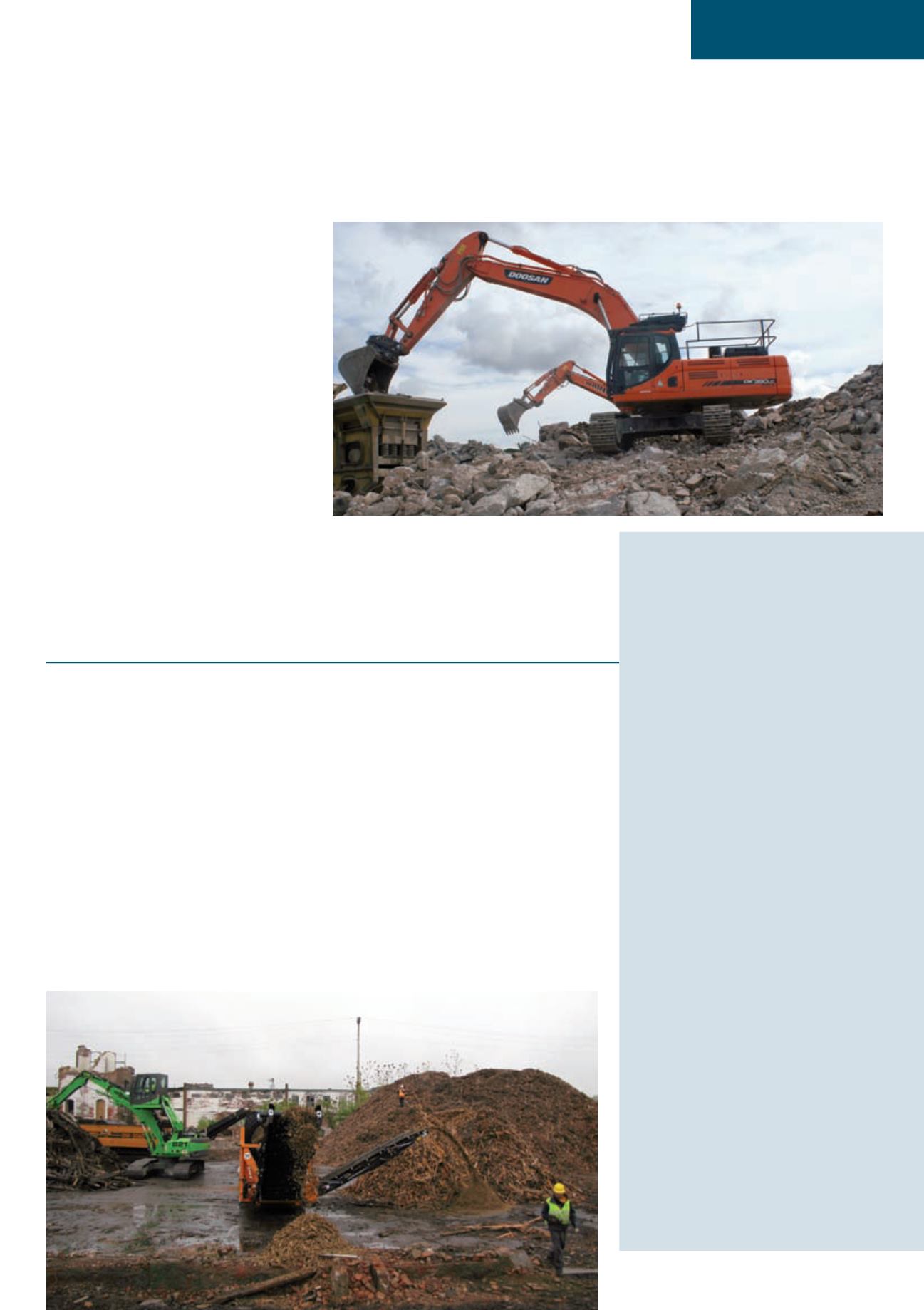

Doosan debuts

with Wring

W

ring Group is currently working

on the site preparations for

a temporary campus facility

that will house 1,000 workers that will be

employed on the construction of two new

nuclear reactors at Hinckley Point C power

station in Somerset. The site was formerly the

home of a British Cellophane factory acquired

by Innovia Films in 1996 that had lain derelict

after the plant finally closed in 2005.

Wring was brought in to clear the

buildings, which it achieved by the end

of 2010. The company is now removing

the substructures and foundations of the

demolished buildings as part of the current

land remediation contract. By the end of

the work, Wring is expecting to have sorted,

recycled and removed more than 250,000

tonnes of material from the site.

Four new Doosan machines are working

on the site, with pride of place going to the

first Tier4 Final/Stage IIIB compliant 39 tonne

DX380LC-3 to be supplied to a UK contractor.

It is working alongside three from a batch of

six new DX225LC machines also acquired by

the company. The DX380LC-3 is powered by

Sorting is king

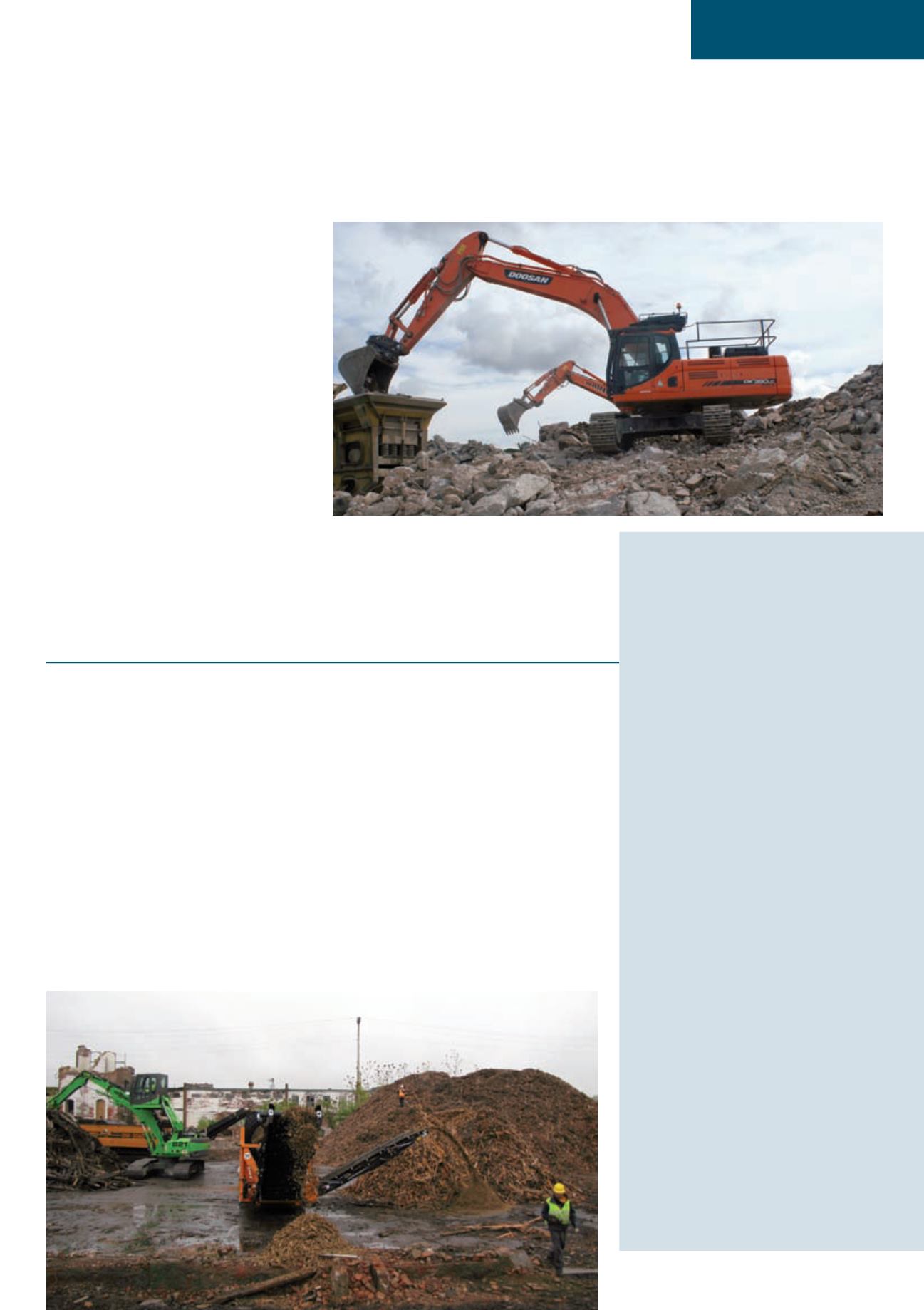

Costello Dismantling has recently completed

the demolition of the 55,742 m

2

(600,000 ft

2

)

Quaker Fabrics textile mill in Fall River in

Massachusetts, USA. The demolition resulted

in the generation of 100,000 tonnes of mixed

waste, with Costello recycling all but 2,000

tonnes that had to be sent to landfill.

Costello used a recently acquired

Sennebogen 821 material handler equipped

with a magnet grapple to feed two mobile

shredders, also recently acquired, to process

the timber waste. According to president Dan

Costello: “We look very carefully at each job

to identify those materials that are most easily

handled and recyclable; the highest and best

use opportunities for each type of material.

We have tailored our equipment fleet and

our personnel training to be disciplined

between the different markets for materials.

The thing we learned early on was the need

to meticulously manage the infeed,” Costello

explained.

“That mainly involves picking out any

heavy metals before the load goes into the

shredder. This will minimise damage and

minimise downtime on that side of the

operation. The maggrapple gives us the

capability to pull any steel present out of the

wood, then load the wood into the grinder

with the same grapple.”

■

Wring Group’s new Stage IIIB compliant Doosan

DX380LC-3 is the first to work in the UK

demolition industry

Finlay solution

ideal for

Cappagh

UK recycling specialist Cappagh Group has

taken delivery of a Terex Finlay 883 screen

from dealer Finlay Plant South East that

it is currently using at its Stanwell, UK,

site for the contractor’s work at Heathrow

Airport, making reject sand that is used

for pipe bedding and filling.

Cappagh is headquartered in

Wimbledon, UK, and has operational and

recycling centres across the south east of

the UK. The company has made significant

investments to establish Aggregate

Recycling Centres, which are strategically

placed to serve customers across the

region. Designed to recycle construction

waste and maximise the production of

recycled aggregates for re-use within the

company’s own construction projects,

these centres provide an environmentally

friendly, cost-effective and uniquely

integrated service.

According to Michael Ferncombe,

managing director of Cappagh Group:

“Flexibility enables us to meet the

challenges of the evolving utilities and

construction market, and the introduction

of high performance plant and machinery

over the years has been key to us meeting

those demands. We have worked with

Finlay Plant South East for more than 15

years to introduce new plant that makes

a real difference to our operations. We

also benefit from excellent support in

terms of service and spares, to ensure

day-to-day operations run smoothly

and efficiently.”

Costello’s new Sennebogen 821 material handler feeding two grinders to

produce graded fuel products from wood waste

a Doosan turbocharged DL08K common rail

six cylinder diesel that achieves compliance

through the use of DPF and EGR. It offers

an 8% increase in torque, delivers 6% more

power at 213 kW (286 hp) at a lower rpm of

1,800 when compared with the engine in the

previous DX380LC model.

■