INTERNATIONAL AND SPECIALIZED TRANSPORT

■

DECEMBER 2013

WIND TURBINE ERECTION

27

New dedication

Alongside redesigns and new additions

to existing cranes, manufacturers are

also designing new models. XCMG, for

example, launched the QUY500W, a

crawler crane specifically designed for

working in the wind power sector. The

crawler can lift a 105 tonne load to a

height of 90 m.

Recent launches from manufacturer

Link-Belt are the 80 ton (72 tonne) RTC-

8080 Series II and the 200 ton (181 tonne)

248 HSL lattice crawler. The manufacturer

also increased the base capacity for the 250

ton (226.8 tonne) 298 HSL.

“The most significant wind project as

of late for Link-Belt has been in California

at the Blattner Energy project in Tehachapi

Pass, north of Los Angeles, in the Mojave

Desert,” Pat Collins, senior product

manager, lattice crawler and telescopic

crawler cranes at Link-Belt, says, “There are

more than 20 Link-Belts working on that

project at various modification yards and

also at individual turbine locations. Nearly

half of those cranes are large Link-Belt 80

to 90 ton [72.5 to 81 tonne] rough-terrain

cranes, and the remainder are smaller

rough terrains and larger capacity lattice

crawler cranes, a 250 ton [226 tonne] 298

HSL and 300 ton [272 tonne] 348 H5.”

Also new to the market is the Terex

Superlift 3800 crawler crane, which can

erect wind turbine hubs up to 3 MW and

110 metres.

The 3800 requires less counterweight

than previous models and, for better

transport, single components weigh less

than 40 tonnes and less than 3 m in width

and height. In addition, the crane has side

outriggers with ground pressure monitors,

a new cab design, and a fall protection

system fitted as standard. It has a maximum

load moment rating of 8,426 tonne-metres.

Making waves

The number of offshore wind farms is also

increasing at a steady rate, even in areas

where the concept had been unpopular. As

a spokesperson from Uchimiya in Japan

points out, this trend is set to increase,

“Recently we worked on an offshore wind

turbine installation project in Kamisu,

Ibaraki Prefecture. Although offshore wind

turbine farms in Japan are not so popular,

>

Variables such as tight radii turns, elevation changes, narrow roads and low clearances on bridges

can be a serious problem for planning transport routes when large equipment is involved. To help

plan these difficult routes, transportation software provider Transoft Solutions uses AutoTURN, a

simulation software that helps plan journey routes to see if they can realistically be made.

The software can simulate rear-steering systems for six specialized vehicle configurations,

including a 19-axle heavy hauler trailer, a wind tower trailer (or Schnabel trailer), a wind blade

trailer, a beam transporter I and II and a booster trailer.

“In Northeast Brazil, wind farms are in coastal regions and the roads there are made of sand

dune soil,” a company spokesperson from Transoft Solutions explains. “Some of the bridges the

special transport trucks have to cross are only rated for loads up to 36 tonnes and components,

like the nacelles, weigh much more than this. The truck drivers also have to deal with oncoming

traffic and navigating narrow roads.”

“Modelling the vehicle swept path

accurately is important to ensure designers

can plan safe and efficient routes for the super

loads,” Transoft’s Steven Chan adds.

SIMULATION PLANNING

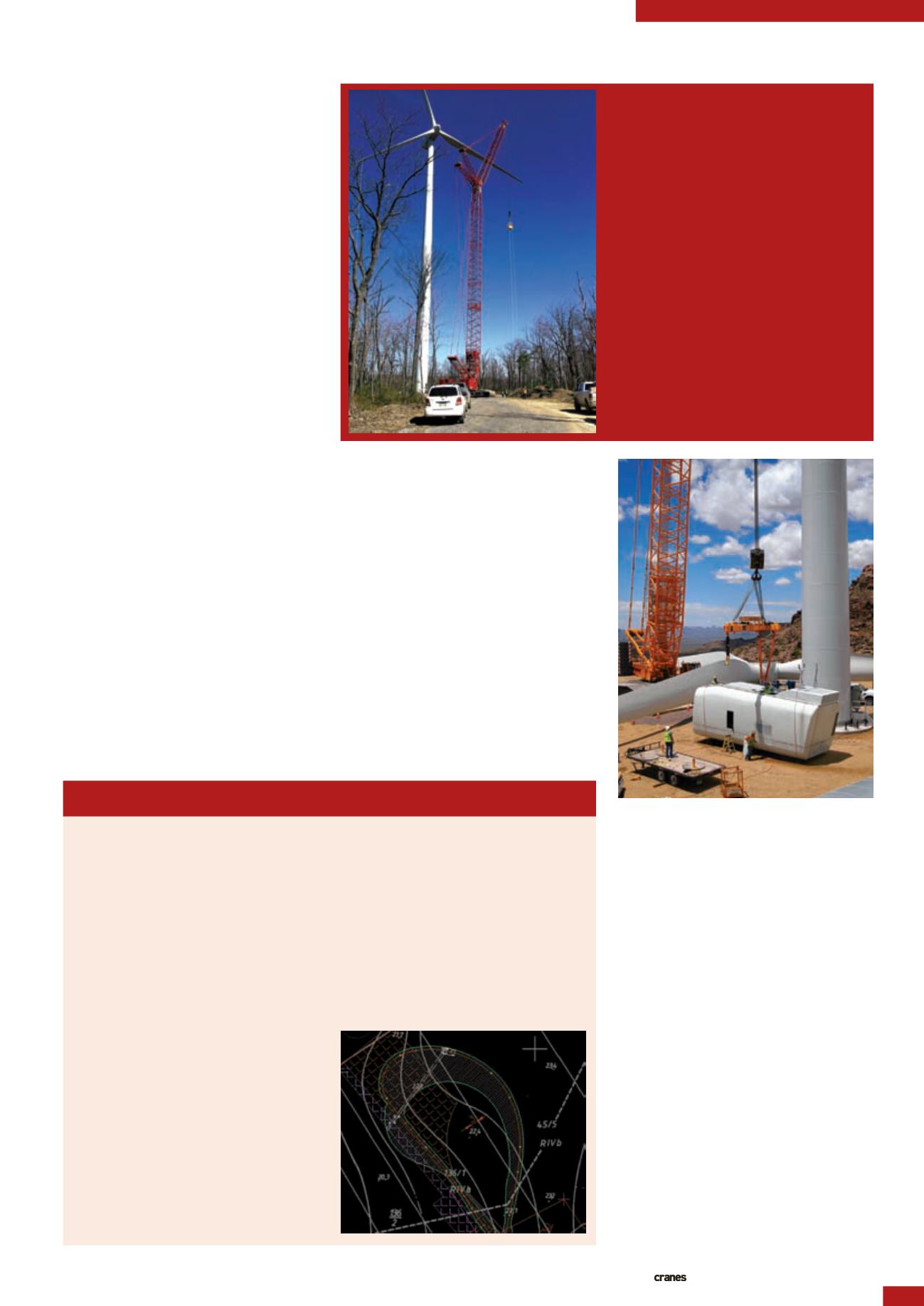

Buckner Companies at the Kingman wind

farm in Arizona, USA. A Liebherr LR 1600/2

in SL3F configuration, a main boom of 84

metres and an 11 m wind jib. The crawler

was used to set 2 MW turbines weighing 86

tonnes on 80 m towers

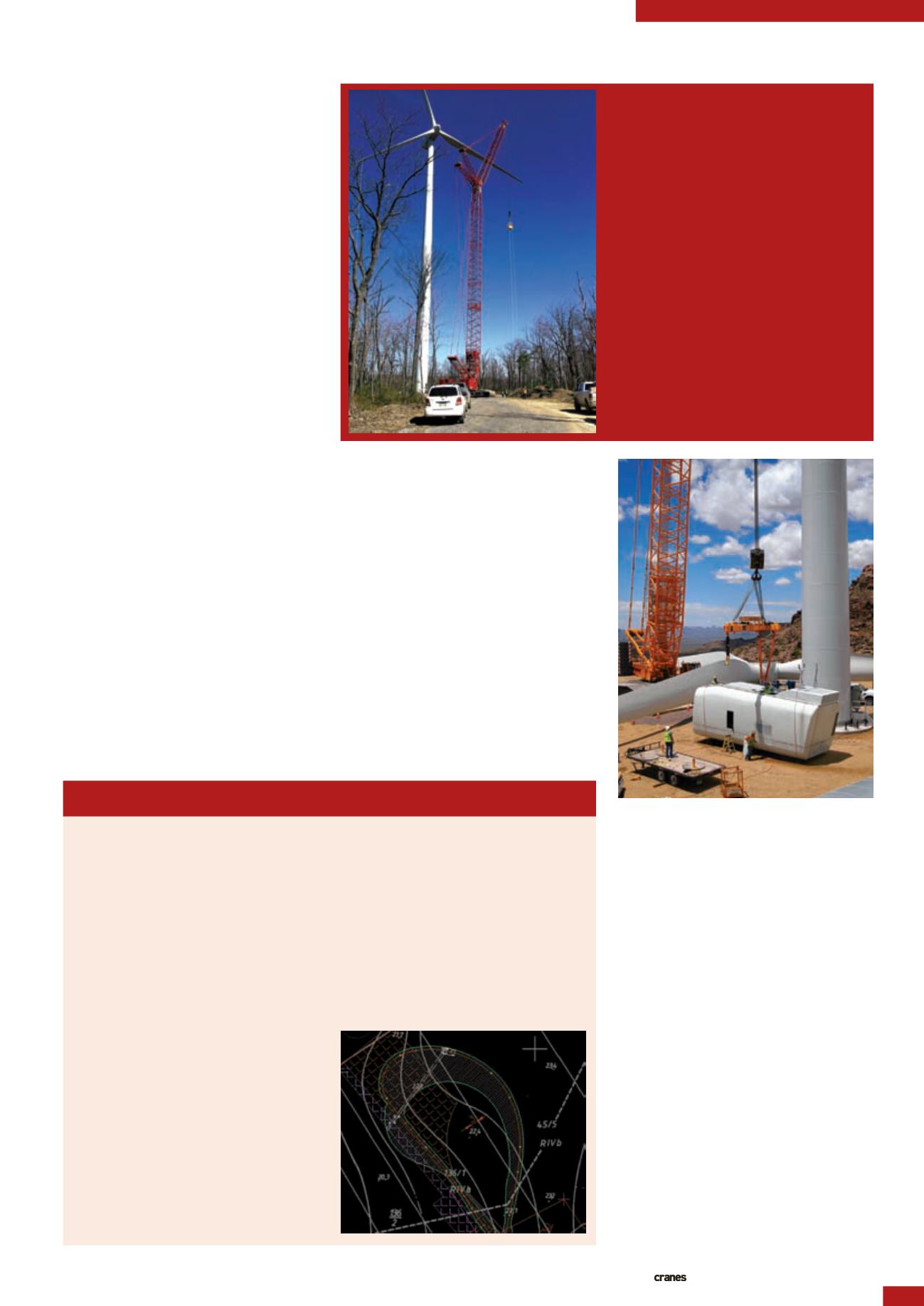

Lomma Crane & Rigging, based in New

Jersey US used a 660 ton (600 tonne) capacity

Manitowoc 18000 crawler crane with a

98 metre boom and a 300 ton (272 tonne)

capacity 2250 crawler with 91 m boom to erect

wind turbines at Sandy Ridge Wind Farm in

Tyrone, Pennsylvania, USA.

In total 25 Gamesa G87 wind turbines,

standing up to 101 m tall, were installed at the

farm. Challenges during the project included

sub zero temperatures, powerful winds,

difficult terrain and large amounts of snow.

Steve Burkholder, Lomma’s heavy lift manager

at the Pittsburg, Pennsylvania, location, said,

“Despite the challenging conditions, our

Manitowoc cranes operated smoothly the

entire time.”

Sandy Ridge Wind Farm has the capacity to

generate 125 GWh of electricity a year.

Once the variables were entered into

AutoTURN, engineers from Próxima

Engenharia evaluated the vehicle swept

path and the in-swing and outswing of

the turbine sections and blades on the

route to wind farm sites

we expect this to increase and to become a

new source of generating energy, more so

as demand continues to rise.”

To help with this growing trend,

Liebherr-Werk Nenzing developed the

CAL 64000-1500 Litronic, a heavy lift

offshore crane. The CAL 64000-1500 has a

lifting capacity of 1,500 tonnes to a working

radius of 31.5 m. The crane has a boom

length of 105 m and is designed as a crane

around the leg (CAL) so it can rotate 360

degrees around one of the four jack-up legs

of the vessel.

“It is capable of installing 5 MW turbines

and rotors as well as the loading and

subsequent safe installation of the heaviest

foundations down to a maximum water

depth of 50 m,” the manufacturer says.