WIND TURBINE ERECTION

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

DECEMBER 2013

24

of a crane needed to build the biggest

wind turbines requires too many trucks

for transportation and too much time

for erection.

In these particular cases, tower cranes

are a serious contender, as Hans-Martin

Frech, Liebherr Werk-Biberach, explains,

“The space needed for the erection of a

tower crane is only around 40 % of the

space needed for other lifting appliances.

Fewer transport vehicles with lower weights

are also required.”

For this niche market, Liebherr offers,

among others, a new model, the 1000 EC-B

125 Litronic flat-top crane, introduced

in April 2013. “The 1000 EC-B 125 has a

lifting capacity of 125 tonnes in the six-

fall version or 100 tonnes in the four-fall

version,” Frech adds, “It is ideal for short

radii of 31.5 m and 36.5 m and for erecting

hub heights of more than 120 m.”

the Northeastern states of Brazil have the

greatest wind potential in the country. In

the southern part of Brazil, the state of Rio

Grande do Sul also has great potential.”

Following the devastation of the nuclear

accident at the Fukushima Daiichi Nuclear

Power Station, Japan is also experiencing

a boom in the wind turbine industry. A

spokesperson from crane rental company

Uchimiya, explains, “Wind energy has

become increasingly popular in Japan as

a new source of electric power with a less

harmful influence on the environment.

This is true particularly after the nuclear

accident at Fukushima Daiichi Nuclear

Power Station.

“We have worked on a number of wind

turbine installation projects, such as the

Arita wind farm in Wakayama and Nishime

wind farm in Akita. On these sites our

cranes included the 650 tonne capacity

Kobelco 7650 and the 550 tonne capacity

Tadano AR-5500M all terrain.”

Remote locations

The race for developing increasingly higher

and larger wind turbines seems to be

coupled with the trend of installing wind

farms in ever more remote areas, including

weaker wind regions, up mountains or in

forests. This poses a number of challenges

for those involved in the installation

process. Carsten Bohnenkamp, director

of special application tower cranes at

Potain, explains, “Remote locations make it

difficult or even impossible to transport a

large mobile crane or crawler crane on site.”

As Bohnenkamp points out, this

could be a potential problem, especially if

forecasts of nacelles weighing between 60

tonnes and 100 tonnes by 2018 come true.

The challenge is that the sheer size

The new generation of wind turbines and the trend of installing them in challenging environments

is having an effect on the design of specialized trailers. To adapt to the needs of wind turbine

installation providers, Tii Group has introduced a number of new products for the industry. First is

the Scheuerle rotor blade adapter, which is designed to navigate tight corners or obstacles, such

as trees or buildings. In addition, the rotor blade adapter can change the position of the rotor blade

when on steep hills or narrow winding rows. The adapter has an angle inclination of up to 60

degrees. Maximum rotation angle is 110 degrees and it is fitted with a wind sensor.

“The rotor blade adapter can be mounted and transported on both a pulled platform trailer

combination as well as self propelled modules,” Christopher Rimmele, Tii Group sales, says. “It

has maximum stability due to a hydraulically-operated, sliding counterweight in longitudinal and

horizontal directions depending on the rotor blade position. In addition to this it also has radio

remote control with display of wind speed, transverse gradient, blade position, ballast position.”

Also from Scheuerle is the wind tower bolster for moving turbine tower sections. It can

be mounted on Scheuerle platform trailers, including the InterCombi, InterCombi SPE, SPMT,

Scheuerle-Kamag K25, or on platform trailers from Nicolas.

“The new wind tower bolster has a lifting and slewing function which is moved by radio or

cable-remote control,” a company spokesperson explains. “In tight bends, the bolster moves the

wind tower up to 750 mm in a parallel position upwards or to one side so that one end of the wind

tower segment is lifted up by 15 degrees. In

addition, the wind tower can be turned to the

right or left.”

The wind tower bolster has a maximum

payload of 80 tonnes and can transport tower

sections with a diameter of 2.8 to 5 metres.

KEEPING UP ON SIZE

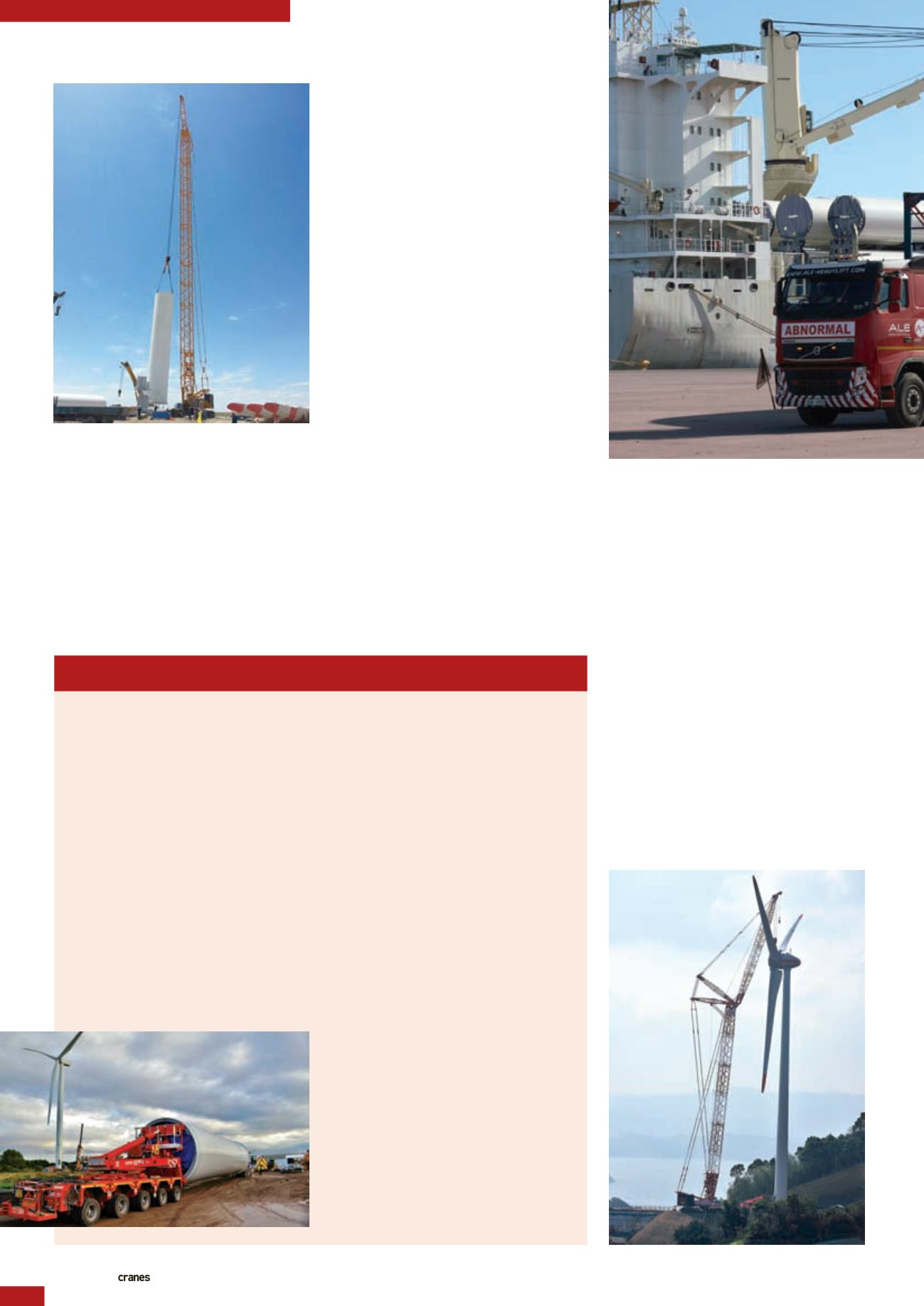

Uchimiya at

work on the

Arita wind farm

in Wakayama,

Japan

All terrain cranes

have also been a

popular choice on

a wind farm area

of Guangdong,

China, where five

XCMG QAY1200

all terrain cranes

are being used

to lift and install

21 units of 2 MW

wind turbines

Plantspeed in the UK transported a

Repower wind turbine base tower section

from Chepstow to Milford Haven on

Scheuerle platform trailers. The 63 tonne

load was 22 m long and 4.3 m in diameter