41

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

DECEMBER 20

13

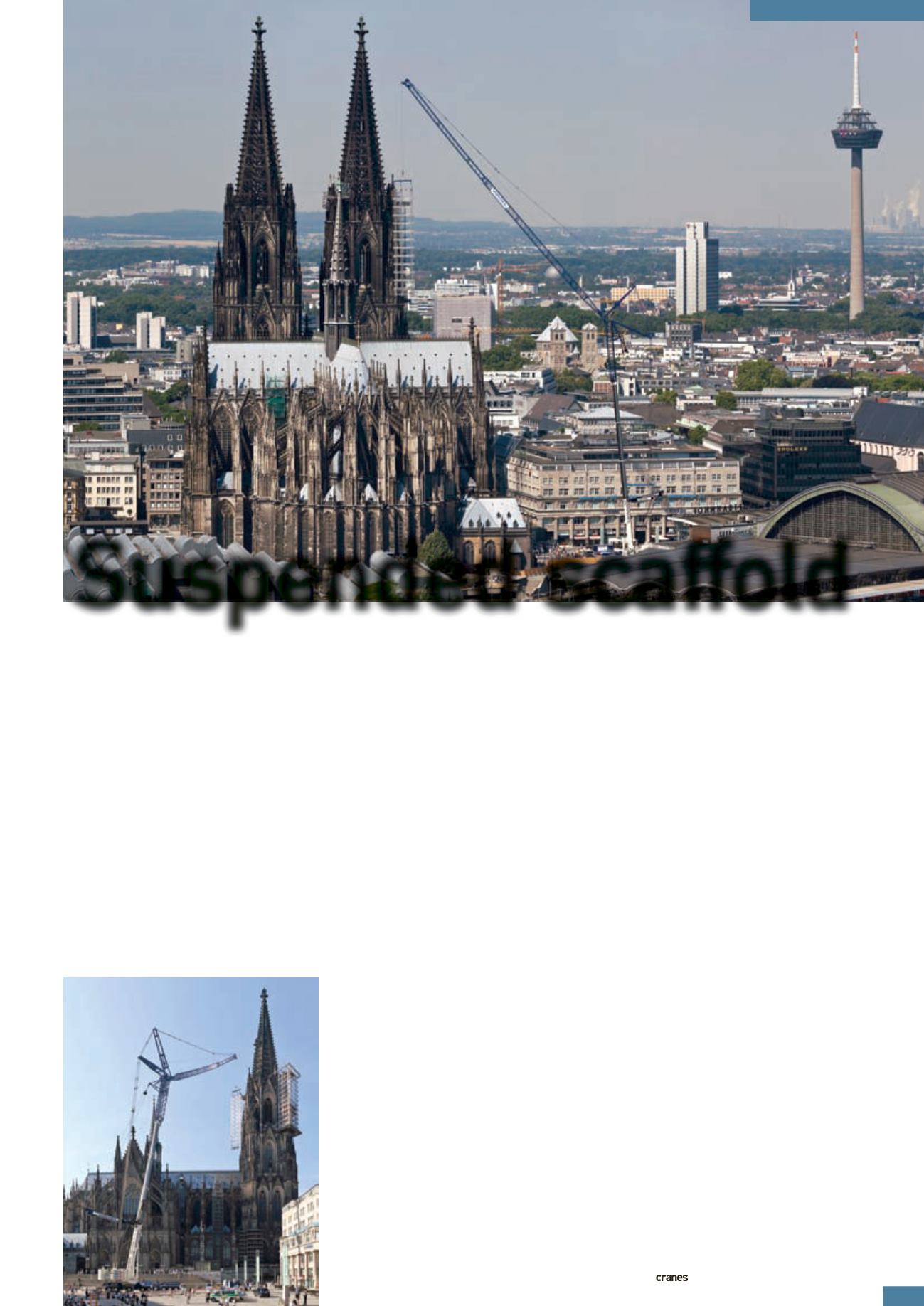

Specialist lifting contractor Wasel in Germany helped to carefully dismantle a hanging

scaffold structure from the ancient Cologne Cathedral in Germany.

IC

reports

on with regard to the erection site for

the crane. The first area of choice was a

position on the pedestrian side on the south

side of the cathedral. This area, however,

was dismissed as a set up site because

the engineering records of the area had

been lost when the Cologne City Archive

collapsed in 2009. It was impossible to

make correct engineering calculations to

erect the crane.

After discussions with the cathedral

administration department and with local

authorities and institutions in the city, the

crane was eventually erected on the station

forecourt at Cologne Central Station.

The site posed several challenges, as

Jürgen Oprée, technical manager at Wasel,

explains, “In the run-up to this job, the

assembly gave us some headaches. We had

to consider station evacuation plans in

our assembly schedules and also had to

keep the escape and rescue routes free at

all times.”

Around 280,000 passengers use Cologne

Central Station every day. A result of

this meant that the crane crew were only

permitted to block certain areas of the

station forecourt needed to assemble the

boom only at night.

Further difficulties presented to Wasel

H

eavy lift company Wasel from

Bergheim in Germany overcame

several challenges to dismantle two

hanging scaffold structures from the north

tower of Cologne Cathedral. One of the

scaffold structures was at a height of

100 metres.

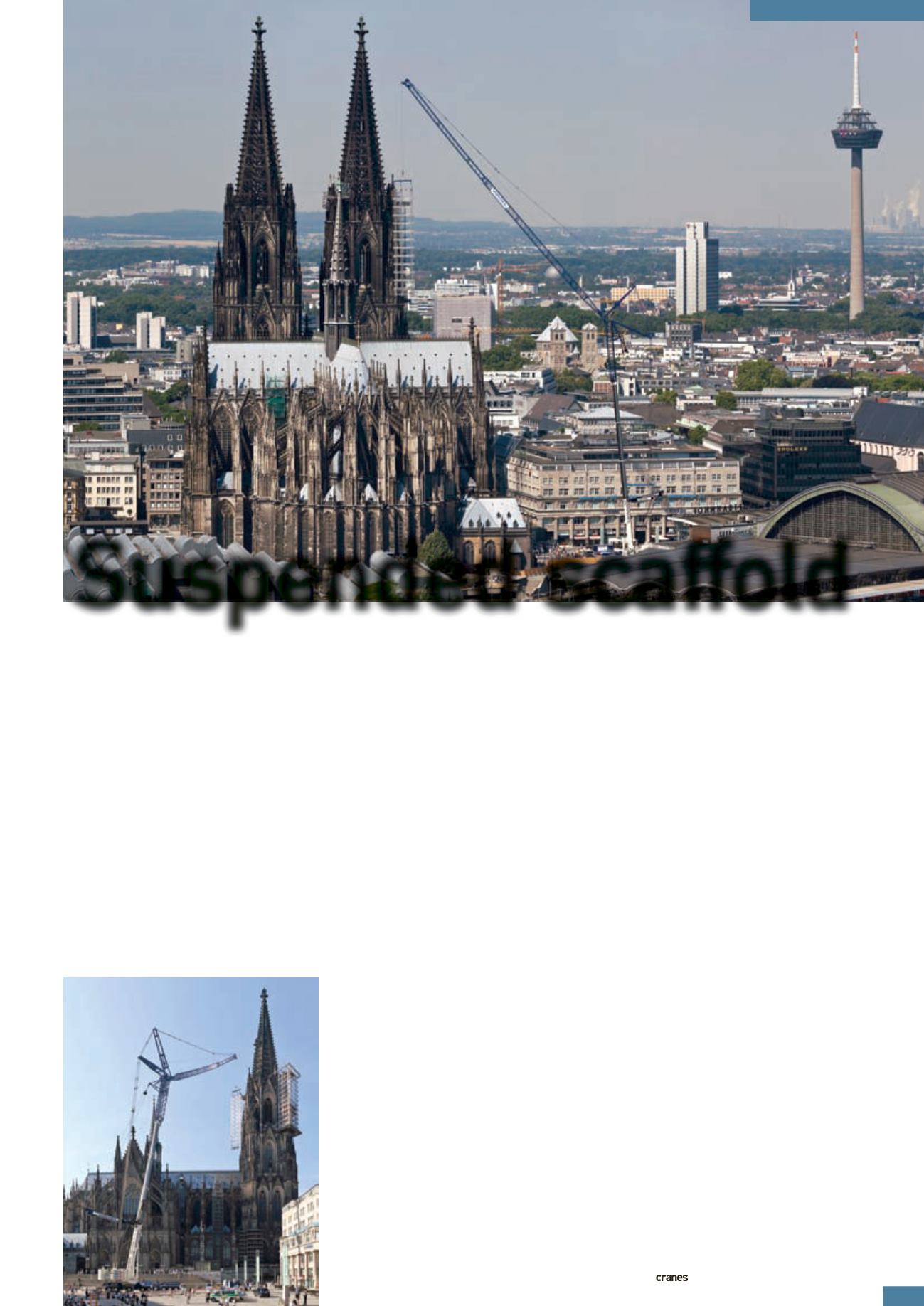

To carry out the tasks, Wasel used a

750 tonne capacity Liebherr LTM 1750-9.1

wheeled mobile telescopic crane configured

with a maximum hook height of 154 m.

One of the aluminium scaffold structures

had to be removed in three sections.

Challenges for the project began early

SITE REPORT

during the project included a small

assembly site of 90 m. This meant the

boom had to be assembled in a suspended

position. It took eight hours to configure

the basic crane with supports, telescopic

boom guys and a telescopic boom

extension, including pivot section.

Part of the job for the team involved

separating the sections of scaffold. Once the

sections were separated the LTM 1750-9.1

was able to lift the scaffold off the cathedral.

The sections measured 7 m wide and

33 m tall. The scaffold sections were then

lifted between the cathedral towers and

positioned in front of the main entrance

of the cathedral. A Liebherr LTM 1070-

4.2 helped with the final positioning of

the sections. Jürgen Oprée explained the

difficulties encountered during the process,

“When we were threading the rear

scaffold out, in some cases we had just

15 centimetres between the load and

the cathedral.

“Just a few years ago a job like this

wouldn’t have been possible in this

manner,” explained Oprée, “from a

technical aspect, maybe, but certainly

not within the short time frame.

In total the task took four hours

to complete.

■

Suspended scaffold

The team separate

the sections of

scaffolding so it can

be lifted off

the cathedral

The first scaffold section is

suspended from the hook of the

LTM 1750-9.1