TOWER CRANES

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

SEPTEMBER 2013

24

and with a tip load of 10.5 tonnes at 42 m

outreach. The main improvements on the

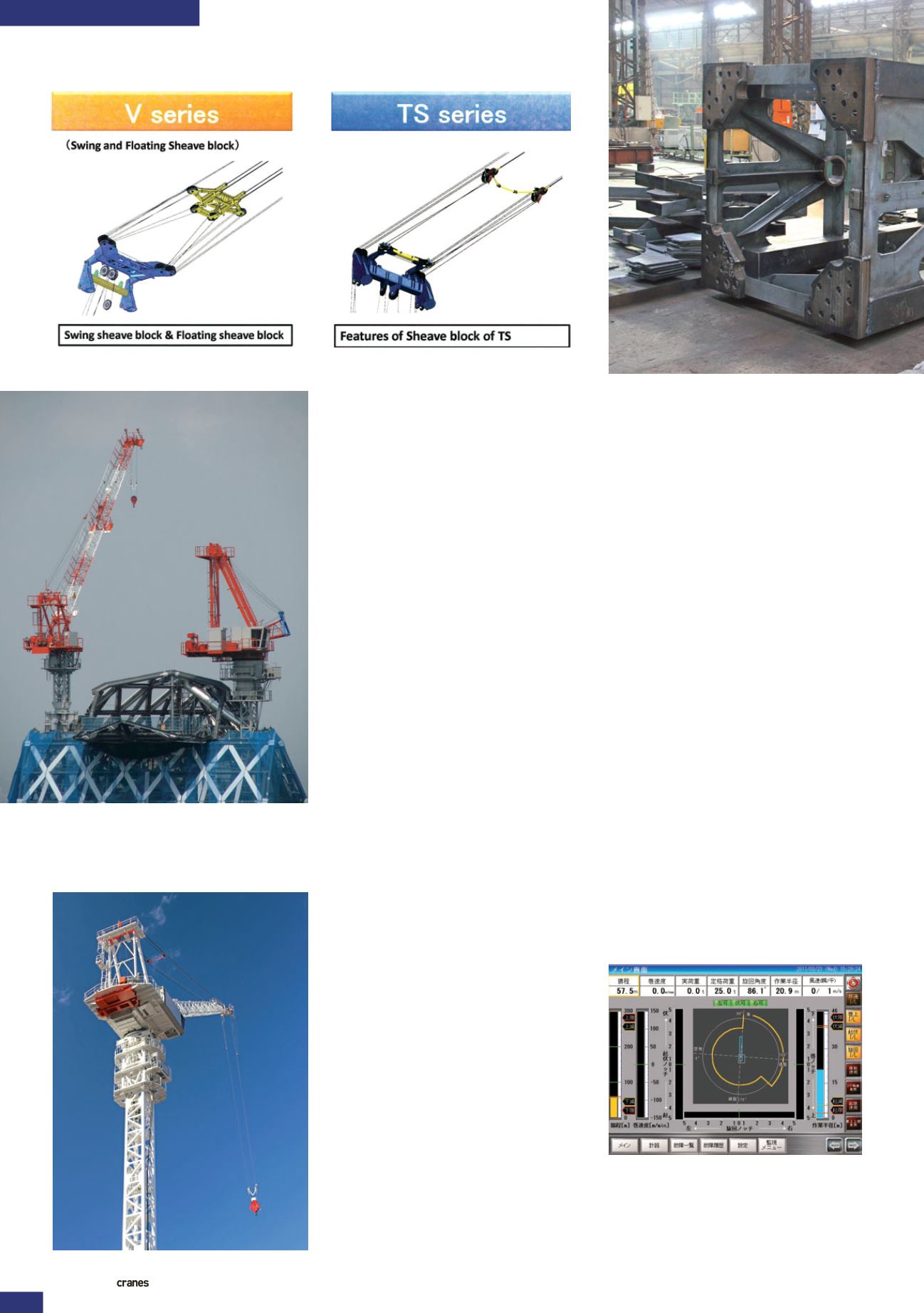

TS series JCC-TS500 include a simplified

floating sheave block design to allow simple

rope reeving and a 1.90 x 1.90 m mast

system, which allows the mast sections to

be climbed through the turntable.

Maximum free standing height has

also been extended to 51 m and a second

hydraulic pump will be used during the

climbing procedure to double the speed of

retracting the hydraulic ram when it is not

loaded.

The already short floor climbing time

of Japanese tower cranes is also reduced

further. On the TS-series the crane upper

will rest on outriggers while the whole

crane, including mast, will be jacked

through the climbing cage at the crane

base section to allow floor climbing in one

climbing process instead of two. The same

mast sections are used for internal and

external climbing as the ratio of external

and floor climbing application in Japan is

still 1:2.

The tail radius of the machinery deck

has also been reduced to 7.10 m to cope

with restricted construction sites.

A mechanical device for detecting the

sway angle of a suspended load is mounted

at the boom head to allow a sensor-based

In the new crane generation a one touch

panel centralises the monitoring of all crane

operating and maintenance information.

The screen shows details for the collision

avoidance system

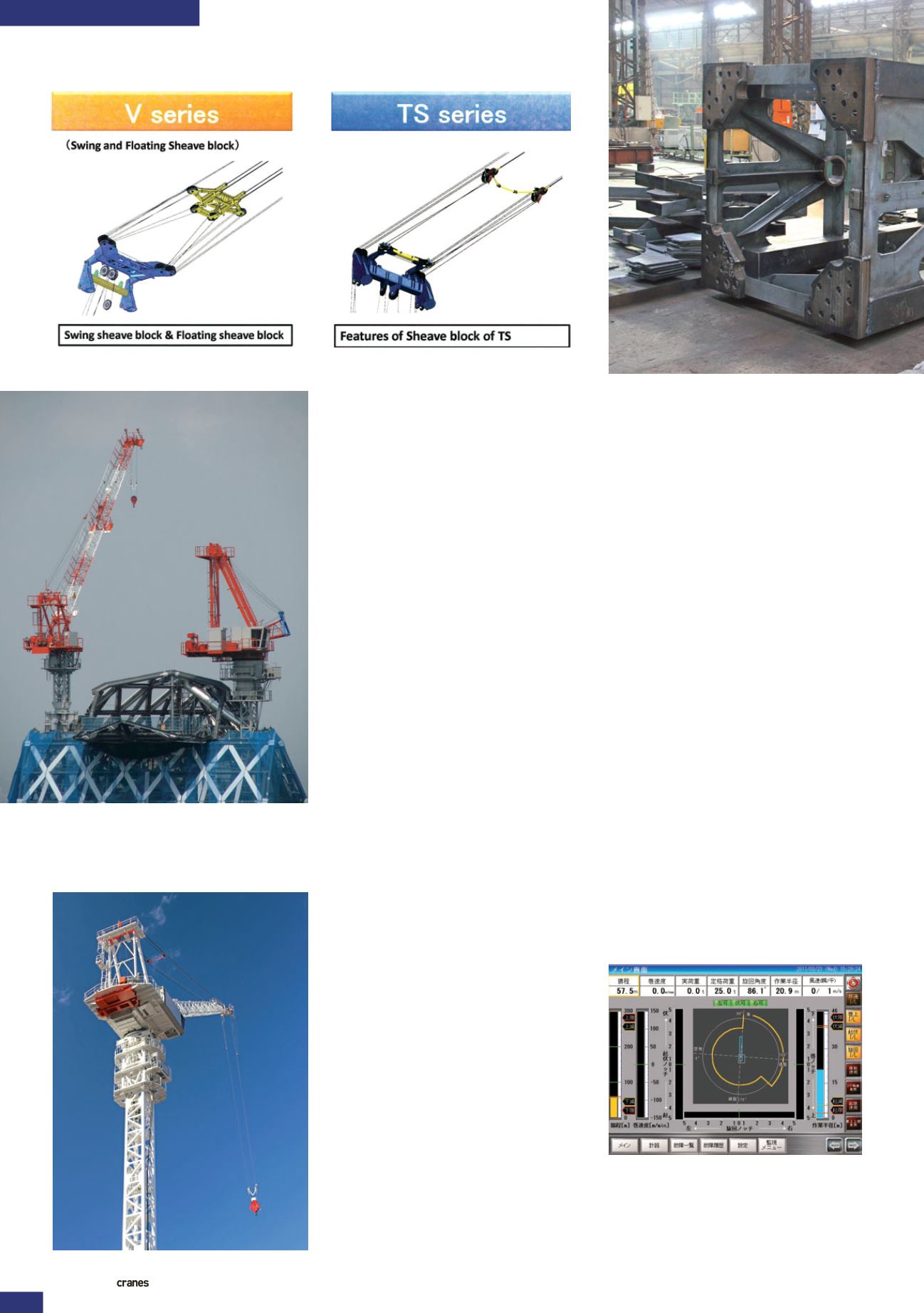

The first JCC-TS500 fully

rigged to its maximum

free standing height on

the IHI test ground in

Yasuura, Japan

drives for all movements, a monitoring

system with touch sensitive display, and

an internet-based remote maintenance

function add to the versatility of the JCC-V

series cranes.

At work

In 2009 IHI supplied three JCC-V720AH

climbing cranes and one JCC-V600 for

the 634 m high Skytree Tower project in

Tokyo. The project pushed the borders of

crane design. The appendix AH stands

for Advanced and High Lift, indicating

the custom-designed extra features for

this spectacular ultra-high climbing crane

application in Japan. Offering a capacity of

32 tonnes at 22.5 m radius, a hook height of

420 m can be achieved at 30 m/min under

full load.

Where the cranes had to operate

at extreme height they were proved to

withstand 100 m/s wind speed with a

mast system 15 % more rigid than the

standard type. In addition, the cranes

had to be installed close to one another.

Booms had to be stored at a steep angle

in the out of service position. A patented

jib restriction device, made up of a second

luffing winch, held back the jib acting

against the main luffing winch. Using the

Slewing Assist Function (SAF) the cranes

were synchronised and moved by on board

computer systems in the out of service

condition to orientate all the jibs in the

same direction following changing wind

directions. A GPS-based three dimensional

collision-avoidance system was also used.

Getting better

To increase productivity, Japanese

construction companies are continuing

to make further improvements in crane

design. At the end of 2012, for example, IHI

announced the JCC-TS (Time Shortening

of Construction) series.

The first example of this new series of

climbing jib cranes, is the JCC-TS500 with

a capacity of 20 tonnes up to 26.5 m radius

Comparison of the floating sheave block of the JCC-V and the new JCC-TS series

The JCC-V60SK helping to dismantle a JCC-

V190SK disassembly crane. On the JCC-V190SK

the blue rigging frame is fitted at the boom foot

section to lower the A-frame by its own means