35

december 2013

international

construction

OEM

New technology

>

Designing more efficient construction

machines starts with their component

parts, a sector where there are changes

afoot.

Chris Sleight

reports.

New

technology

I

t would be easy to see the construction equipment industry

as conservative and unsophisticated, with the design of

machines rooted firmly with steel structures, diesel engines

and hydraulic power. But it is an industry that is increasingly

embracing new materials, new technologies and more

sophisticated components, not to mention a more sophisticated

approach to design.

Why? The drivers of greater fuel efficiency, greater productivity

of the finished machines, greater reliability and preferably lower

cost mean manufacturers and their component suppliers have to

look at new approaches to design.

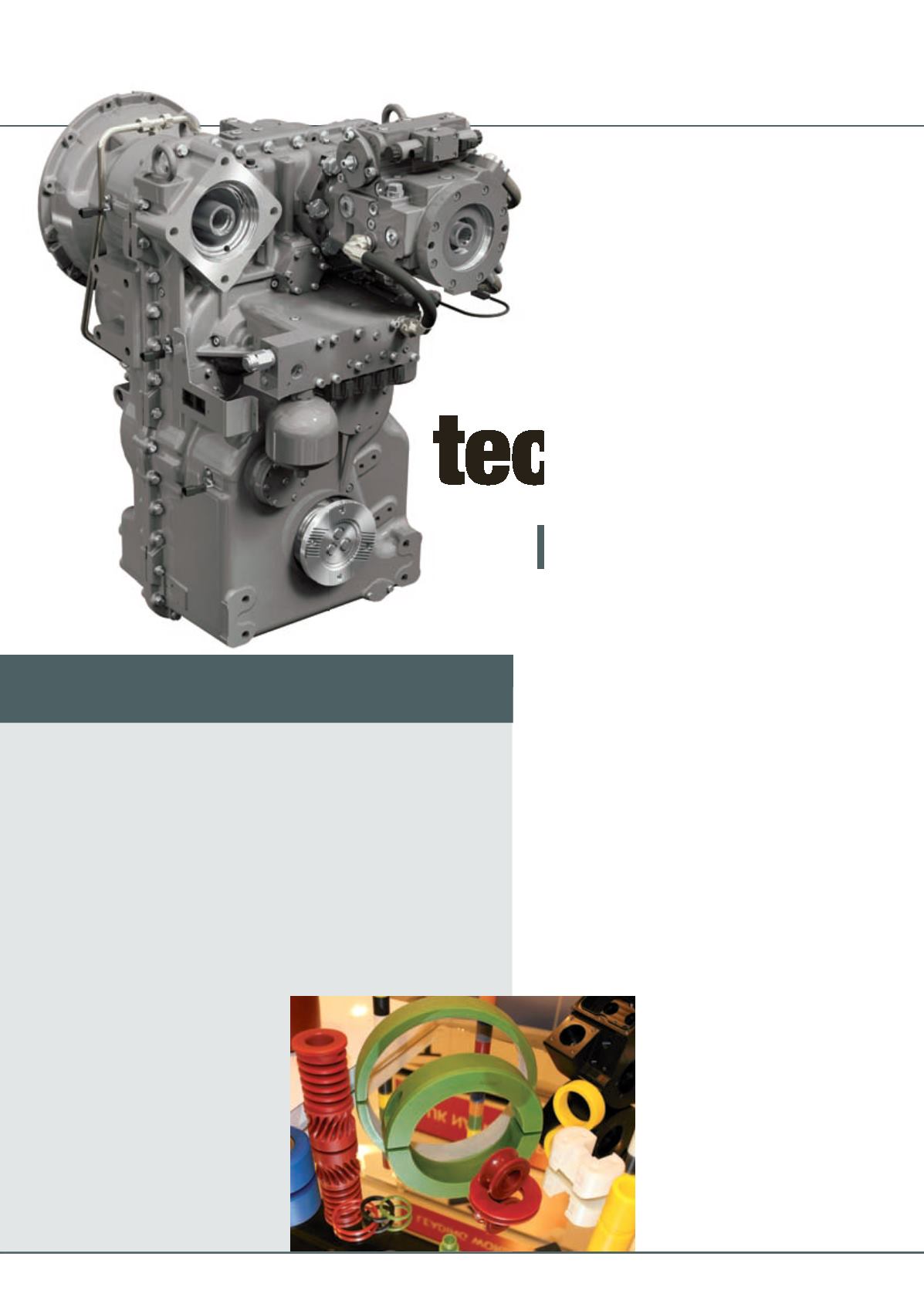

One example of this is the development of hybrid hydro-

mechanical variable transmissions (HVTs), such as the R2

system jointly developed by Dana and Rexroth, and unveiled

at this year’s Bauma exhibition. Combining a hydrostatic drive

(Bosch’s speciality) and mechanical drive (Dana’s forte) into a

single unit means it is possible to reap the advantages of both

technologies. The hydrostatic drive is good at low speeds, where

mechanical systems are inefficient, while the mechanical system

is better at delivering high speeds.

The R2 is designed for loaders, graders, industrial lift

trucks, reach stackers, forestry skidders and other off-highway

applications with a 135 to 195 kW engine. Dana Rexroth said

it achieved fuel savings in the drivetrain of up to -25% when

compared with the same loader fitted with a conventional torque

converter transmission.

Jeroen Decleer, managing director of Dana Rexroth

Transmission Systems, said, “The R2 is

a truly innovative transmission platform

that combines Dana’s and Bosch

Rexroth’s deep knowledge of powertrain.”

Another advantage is that the R2

provides step-less acceleration (i.e. no

gear changes), while physically it is more

or less the same size as a conventional

torque converter.

One way of looking at what devices

like the R2 do, is that they break the link

between engine speed and vehicle speed.

This means the engine can be run at a

steady speed at its most efficient point in

terms of revs, torque, fuel efficiency and

Alternative materials

Nylon has many uses in construction machinery

T

he use of polymers in construction equipment is by no means limited to cosmetic touches

and weight-saving body panels. In fact Leicester, UK-based Nylacast has been supplying

various functional nylon products to industry OEMs for more than 35 years.

One of the classic applications is for wear pads in telescopic booms. The ability to impregnate

nylon with a lubricant – or other additive – has advantages according to construction sales

engineer, Dan Wilson, “Usually we produce something that has a longer life than the traditional

component, so it becomes a fit & forget part that lasts the life of the vehicle,” he said.

There are other advantages besides removing metal-on-metal contact. The nylon is light, so

that translates into more useful load capacity for the boom because the dead weight is reduced.

The lower friction also means there is less fuel consumed in moving the boom in and out.

Another key product is Nylacast’s bushings, which replace older materials like phosphor

bronze. The company says its solution can provide as much as 25 times longer services life.

“Cost can be a challenge if you are up against a cheap casting, but that might be something

that requires a lot of maintenance over the life of the machine. We offer something that has a

better service life and that makes like easier

for OEMs and dealers, because they’re not

always out in the field fixing things,” said Mr

Wilson.

And although the company makes products

for generic applications, it likes to get involved

from the outset with OEMs.

Group CEO Mussa Mahomed said, “We tend

to be involved with the customer from the

design stage, looking at all factors from early

on, so we understand. Clearly there are lots

of polymer manufacturers, but from our point

of view, we are different in that we work in

design and solutions, so we are the first call in

lots of cases.”

The R2 HVT

is its latest

powersplit

system

from the

50:50 joint

venture

between

Dana and

Bosch

Rexroth.