OEM

New technology

so on, without having to stray into the

low speeds where diesel engines do not

perform well.

Dana itself has been working on the

Spicer PowerBoost System, a new line of

integrated hydraulic-hybrid powertrain

concepts which capture energy that would

normally be wasted in the drivetrain and

hydraulic systems. The company says this

could reduce fuel consumption by -20%

to -40% depending on the application

and duty cycle.

It added that Spicer PowerBoost could

also reduce total owning and operating

costs by increasing productivity, reducing

maintenance, and allowing for the use of

a downsized engine.

Aziz Aghili, president of Dana Off-

Highway Driveline Technologies, said, “In an era when

equipment manufacturers are finding it difficult to identify

incremental gains in efficiency, Spicer PowerBoost offers a

tremendous leap forward in productivity and reduced costs that

easily fits into existing design envelopes.”

The heart of the system is a hydraulic accumulator, which

captures waste energy. This can then be access as required, for

parts of the cycle such as accelerating from a full stop, lifting a

load, or driving into a stockpile and so on.

It can also be configured to minimise idling by shutting off

the diesel engine and accessing power

captured in the accumulator

for vehicle operations that

consume low amounts of

energy, such as inching,

light working conditions,

and low travel speeds.

Deep seated development

Heating, cooling and new safety systems form KAB

S

eats with a heater function and ventilation system are among the advances from KAB

Seating, part of the US-based Commercial Vehicle Group.

The company said that operators would feel the benefit of KAB HV seats which are

designed to combat extremes of temperature. The heater system is designed to warm up the

joints to prevent muscle ache in cold weather, while the air cooling system worked to overcome

the unpleasant effects of overheating such as sweating and skin irritation.

As well as the heating and cooling technology, it has KAB Kool – the application of a special

fabric coating that actively draws heat away from the body surface if the operator begins

to overheat. It also returns any stored heat back to the subject if the surface temperature

subsequently drops. KAB said the net effect was to manage the surface temperature of the seat

more effectively, providing a more comfortable environment.

Among other developments is the KSS inflatabelt. This is an airbag folded into the sash

section of the three-point belt, which pins the operator to the seat and preventing excessive

movement in the event of a crash or roll-over. Developed for the automotive industry, it is

already in use on some US vehicles.

The more familiar seats in KAB’s range are the 500, 600 and 800 Series air and mechanical

suspension seats for construction machines, which are available in configurations including

three-point harness, four-point harness and a pod with integrated joysticks.

It also has the Compact Series of air and mechanical suspension seats for smaller machines,

and a further development from this, the Sentinal seat, which carries over features and the

design flexibility of bigger units.

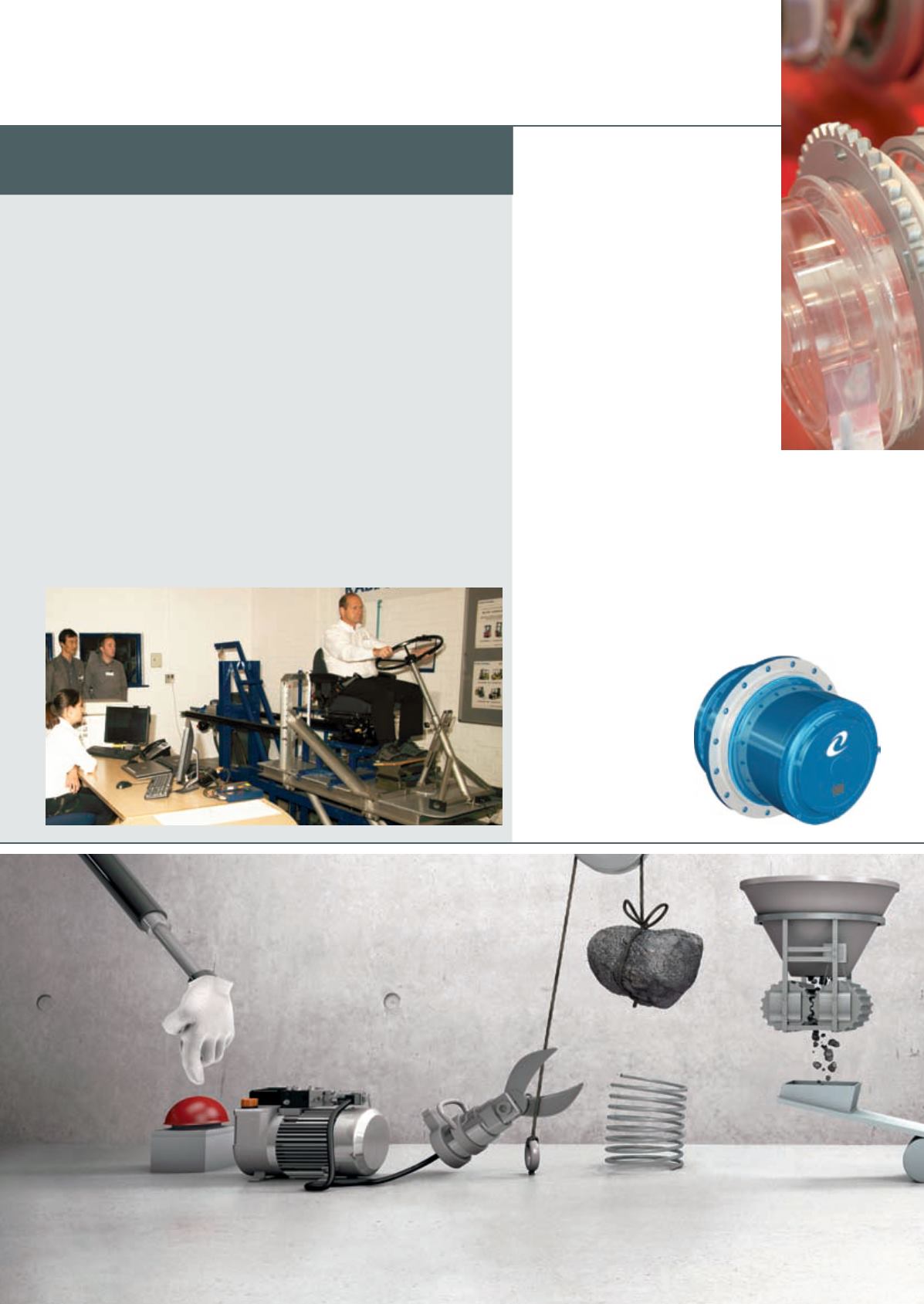

Comer’s new PGRF-11003

heavy duty track drive for

tracked mobile equipment.

The principle is simple. It doesn’t matter which project

you have coming up. Our professional know-how is

here to support you right from the start. From the early

stages of planning and development we create individual,

industry-specific and sustainable hydraulic solutions.

Your advantage: more flexibility, more efficiency, more

reliability and innovative technology. Make it simple:

Contact us. The sooner, the better.