EQUIPMENT

60

international

construction

july-august 2013

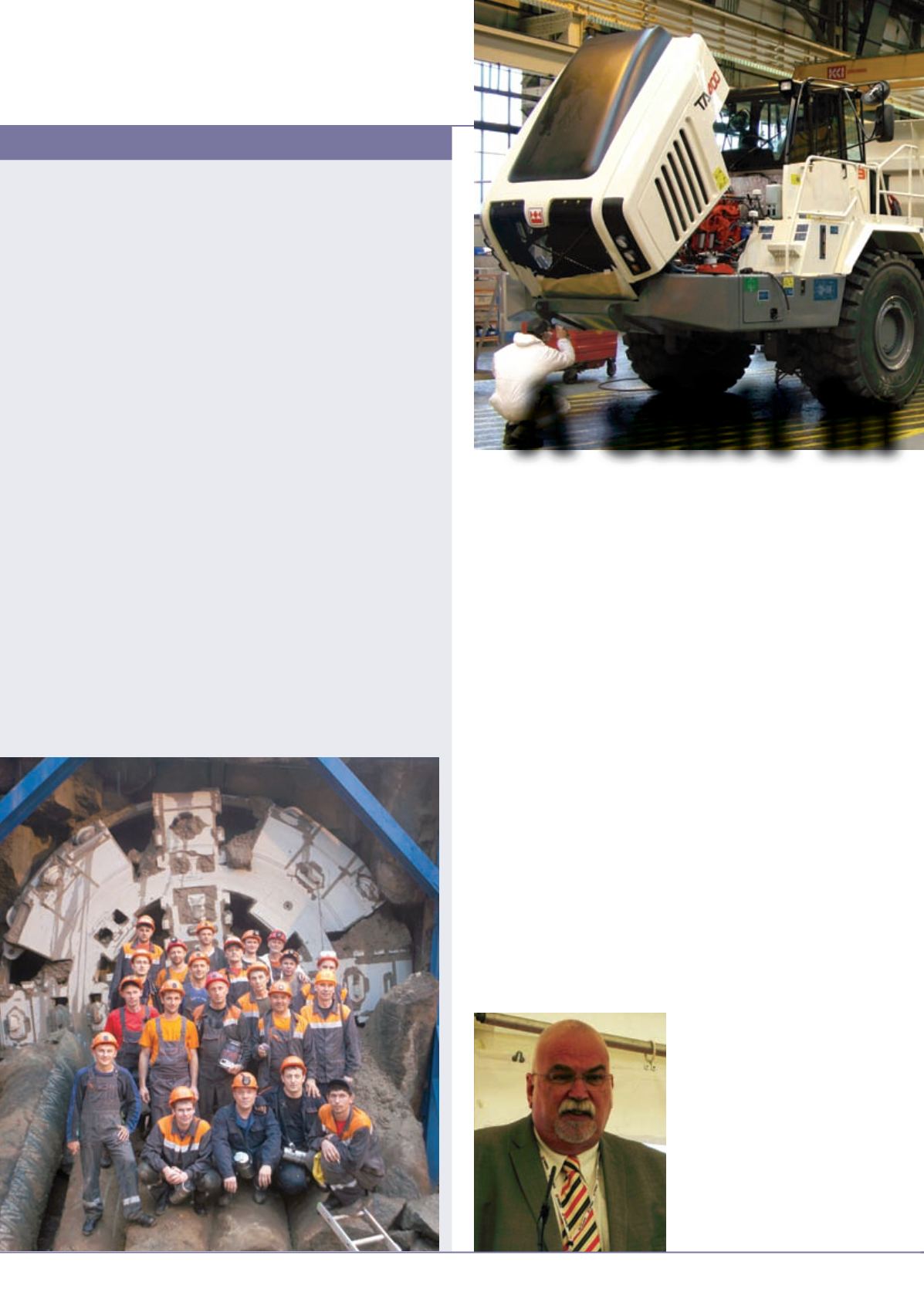

Terex is pushing more and more into emerging

markets with both its articulated and rigid frame

haulers.

Helen Wright

reports.

T

erex’s 28,000 m

2

off-highway

truck factory in Motherwell,

UK, has seen a US$ 5

million investment in production

line equipment for both its rigid

and articulated dump trucks (RDTs

and ADTs).

Production is poised to increase

in-line with new opportunities.

While the factory can produce up

to six ADTs and two RDTs per day

running at maximum capacity, its

current production target is 400

ADTs and RTDs combined for

2013.

Demand in the mature markets

of North America and Europe may

have softened in recent years, but

sales of both ADTs and RDTs are

increasing in emerging markets, and

Terex is eyeing these opportunities.

John Mlonek, commercial sales

manager at Terex Construction,

said, “We have seen a dramatic

change in recent years – the whole

emphasis has shifted towards

emerging markets.”

Mr Mlonek said the company

was considering opportunities in

the world’s growth markets, and

wouldn’t rule out further joint

ventures. Terex has experience in

this field – last year, it established

a joint venture with Russian

Machines to manufacture

construction and road building

equipment in Russia, and also set

up a joint venture partnership in

China with Sinomach to produce

truck cranes.

“With the mineral wealth of

Africa, Russia and Asia, we have to

think of our options,” Mr Mlonek

said. “It may be in the future that

we will look at joint ventures in

Africa and elsewhere – we are

considering our options.”

The largest ADT model Terex

manufactures is the 40 tonne class

TA400 – part of its Generation

9 range that also includes the

30-tonne class TA300 and

25-tonne class TA250. Terex also

manufactures five RDTs, from 32

tonnes to 91 tonnes payload.

A shift in

John Mlonek, commercial sales

manager at Terex Construction:

“We have seen a dramatic change

in recent years – the whole

emphasis has shifted towards

emerging markets.”

RUSSIA

Metro breakthrough

The first of three Robbins earth pressure balance (EPB) tunnel boring machines

(TBMs) excavating the Moscow Metro has made its breakthrough. As well as

finishing the bore early in late May, the project saw a new Russian record set

by the 6.2 m diameter machine, with an advance of 37.8 m being achieved in a

single day in April 2013 – the greatest ever achieved for a machine in this class

in the country.

Launched in the winter of 2012, the TBM achieved advance rates of 150 m

per week. “The soil condition, crew experience, rigorous schedule, continuous

conveyor, and the reliability of the Robbins TBM are all factors that helped

achieve the record,” said Vadim Bocharov of contractor SK MOST.

The machine will now be disassembled in the receiving station site and

launched on an additional 1.4 km tunnel in the last quarter of 2013. It is one of

several Robbins EPBs on the massive metro project where dozens of TBMs are

operating simultaneously. Two 6.6 m diameter Robbins EPBs are excavating

left and right-hand tunnels, each 2.0 km in length, for contractor Engeocom. A

third machine refurbished by Robbins for Engeocom, nicknamed “Julia”, is also

excavating a 2 km section of tunnel.

Ground conditions in the city are said to be challenging, consisting of fine sand,

gravel, loam, stiff clays and boulders. The EPBs are designed for the conditions,

with active articulation to enable excavation of tighter curves without the risk of

tunnel segments deforming. Two-component back-filling is being used to reduce

the risk of settlement at the densely urban tunnel sites. Mixed ground cutterheads

reinforced with abrasion-resistant wear plate give the option of changing the

carbide knife-edge bits with 17-in (432 mm) disc cutters, depending on the

conditions.

Moscow’s Metro Development Program, unveiled in 2012 by the Moscow

Government, calls for 150 km of new metro lines to be build in the next eight

years. Work thus far has been around the clock, with close to 18,000 workers

and specialists engaged in the projects. Their number is expected to reach

35,000 by the end of 2013.

Terex

■

Robbins

HIGHLIGHT