EQUIPMENT

64

international

construction

july-august 2013

JCB

JCB has entered the six

cylinder diesel engine

arena with the launch

of the Dieselmax 672,

and has also introduced

other new machines.

Lindsay Gale

reports.

J

CB has announced its entry

into the six cylinder diesel

engine arena with the launch

of the JCB Dieselmax 672, the

result of a UK£ 45 million (US$ 69

million) development programme.

To date, the company has built

more than 250,000 four cylinder

units since production began, and

the new engine is the next logical

step in its engine development

programme. It will be produced on

a dedicated line at the JCB Power

System’s facility in Derbyshire, UK.

The Dieselmax 672 is based on

its 4.8 litre four cylinder engine,

providing a high commonality of

parts, and will be available in four

ratings – 140 kW, 165 kW, 190

kW and 225 kW, with a maximum

torque of 1,200 Nm.

“The move into six cylinder

engine production is a historic

moment for our business and a

natural step to take and we look

forward to setting new standards in

performance and fuel efficiency.”

iC

Machine updates

Reduced emissions for excavators and loaders

A

t the same event that the new engine was announced, JCB

showed off a number of machines, including additions to its

latest generation of JS excavators that meet the requirements

of the Tier 4 Interim/Stage IIIB emissions legislation.

The new machines were the tracked 17 tonne class JS160LC and

22 tonne class JS220LC, and the wheeled 16 tonne class JS145, all of

which are powered by JCB’s Ecomax four cylinder diesel. In addition,

the company unveiled two Isuzu-powered models, the 24 tonne class

JS240NLC and38 tonne class JS360LC.

Also on show for the first time were two new wheeled loaders, the

8.2 tonne 411 and 9.6 tonne 417, the use the Tier 4 Interim/Stage IIIB

compliant 4.4 litre JCB Ecomax engine that delivers 93 kW in the 417

and 68 kW in the 411. The 411 sports a 1.2 m

3

capacity bucket as

standard, while the 411 is a 1.6 m

3

bucket capacity machine.

Firing on all six cylinders

According to JCB, the new engine

will offer a substantial saving in

fuel consumption of up to 8% over

engines previously used in its JS

excavator range. It is the result of a

two-year development programme

and already has undergone more

than 50,000 hours of testing, much

of which was done in the field.

It initially will be available as a

Tier 2/Stage II unit for machines

being sold into less regulated parts

of the world, such as Russia, Brazil

and China.

The first machines to see the new

engine will be the company’s JS330

and JS360 tracked excavators.

Other machines will be offered

with the JCB engine option as time

progresses.

According to Tim Burnhope,

JCB’s innovation and product

development officer, a Tier 4 final/

Stage IV version should be available

by mid-2015.

Of note is the fact that JCB’s

Ecomax engines meet the current

engine emission requirements

without the use of a diesel

particulate filter or selective

catalytic reduction.

Emissions compliance is achieved

through the use of exhaust gas

recirculation, a variable geometry

turbocharger, common rail fuel

injection and a highly efficient

combustion process.

JCB chairman Sir Anthony

Bamford said, “In a relatively short

space of time we have become a

major producer of engines. Today

more than 70% of JCB machines

are powered by our engines.

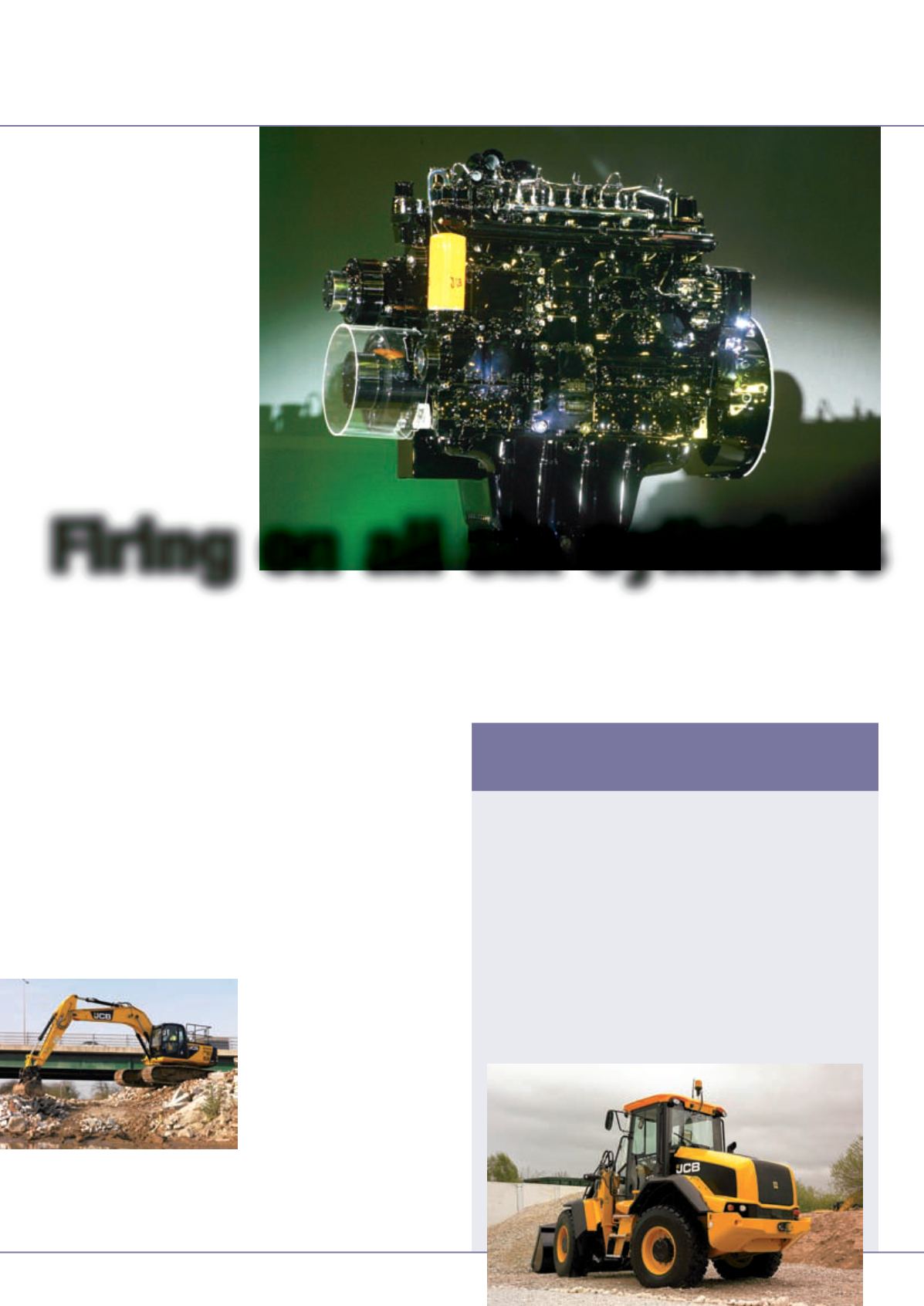

JCB’s new six cylinder

Dieselmax 672 diesel

engine was unveiled

at the company’s

Rocester, UK,

headquarters

The JS220LC is one of two tracked

excavators that now conform

to the latest engine emissions

regulations through the use of an

Ecomax 4 cylinder engine