international

construction

september 2013

CRUSHING AND SCREENING

50

Choices, choices

However, the rainy climate and clay

material it handles puts demands on its

screening media, especially when it comes

to avoiding blinding and pegging.

Having had trouble producing

aggregates for a road project from clay-

contaminated materials using traditional

mesh, the company turned to distributor

Elrus Aggregate Systems for a solution.

The recommendation that came back

was to use Major Wire 7/8 in (22 mm)

Flex-Mat 3 Series D Tensioned screen media, and this produced

dramatic results.

“The operation went from not being able to produce at all in

marginally rainy weather to being able to operate through heavy

downpours. We’ve recommended Major Wire’s Flex-Mat 3

screen media before and knew it could stand up to the challenge

of screening sticky, clay-ridden material,” said Matt Armstrong,

dealer representative at Elrus Aggregate Systems.

The self-cleaning media allows producers to increase open

area, create more screening action and eliminate blinding

and pegging problems as the wires are able to vibrate

The Petaquilla Gold Mine near Panama City, Panama is

unusual in that it produces aggregates as well as precious metals.

Contractor Panama Development of Infrastructure (PDI) is

using a range of Sandvik drills, crushers and screens at the facility

for the diverse production requirements.

Equipment on the site includes a Sandvik DX800 drill rig,

UJ440i mobile crusher and QA450 triple deck Doublescreen

mobile screener, supplied by national distributor Grupo Tecún.

David Baralt, general manager and chief operations officer at

Servicios Mineros de Petaquilla said, “We are seeking friendly

suppliers, who understand how their

products are connected to our production.

We strongly believe in Sandvik for the

recognised quality of their equipment

worldwide.”

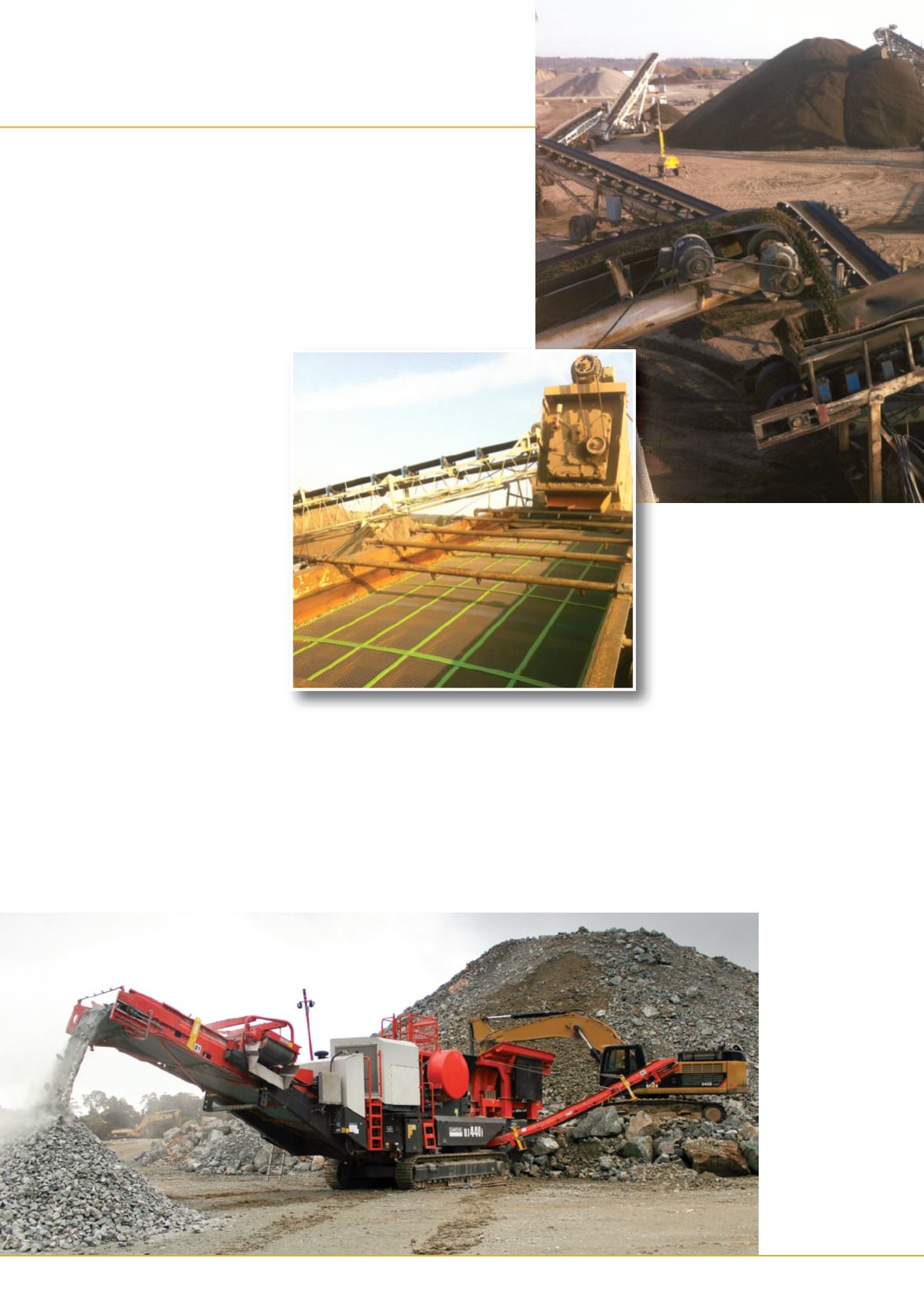

The UJ440i jaw crusher is used to

process Andesite rock from the quarry,

crushing down from 700 mm to

150 mm, at a production rate from

450 to 500 tonnes per hour.

The company also uses a QA450

triple deck Doublescreen, which is able

to achieve a production rate of up to

600 tonnes per hour, depending on the

material, the feed size, and the required

fractions. It can produce four material

sizes, plus an oversize from the grid and

the high production capability is due

to the patented Doublescreen screen

box, which features two independent

triple deck screen boxes. These have

independent drives, that are able to have

their amplitudes and screen angles adjusted depending upon

application.

Components

And the choice of components such as screening media can be

just as important as choosing the right capital equipment, as

Sundre Contracting Co. of Sundre, Alberta, Canada found out.

The company produces more than 30 different product sizes –

from 1.6 mm fine sand to 305 mm screened rock for a range

of customers from road builders, concrete plants and even golf

courses.

Sundre

Contracting’s

crushing &

screening plant

The wash plant, fitted with

Major Wire’s Flex-Mat 3

This Sandvik

UJ440i mobile

crusher is used

to produce

aggregates from

a unique site in

Panama which is

also a gold mine.