HAULERS

Truck upgrades

It is powere by a Cat C7.1Tier 4 Final

emissions-compliant enginewith a power

output of 186 kW.

The machine also features a rear-view

camera and a cab designed with a roll-

over protective structure (ROPS).

Meanwhile scraper maker K-Tec

Earthmovers said customer demand had

driven its latest releaseof a fully integrated

scraper system, which it claimed can double the amount of

material hauledwith the same construction power unit.

Its 1233ADT scraper adds a hitching system on its rear tail, to

accommodate the attachment of a further scraper.

The company added that an operator is able to use responsive

joystick control functionality inside the ADT to first load the

lead scraper, and then fully load the rear scraper.

A digital display screen is also included in the cab for visual

operating details, tracking load count productivity.

The company said its ADT train scrapers result in a significant

advantage in earthmoving, offering the ability to travel at more

than 30mph (48 km/hour) down haul roads, which improves

cycle times.

As self-loading andunloading haulers, scrapers canbe used for

precision grading and dumping; be push-loaded for enhanced

loading time; or even be top-loaded via excavator for heaped

hauling.

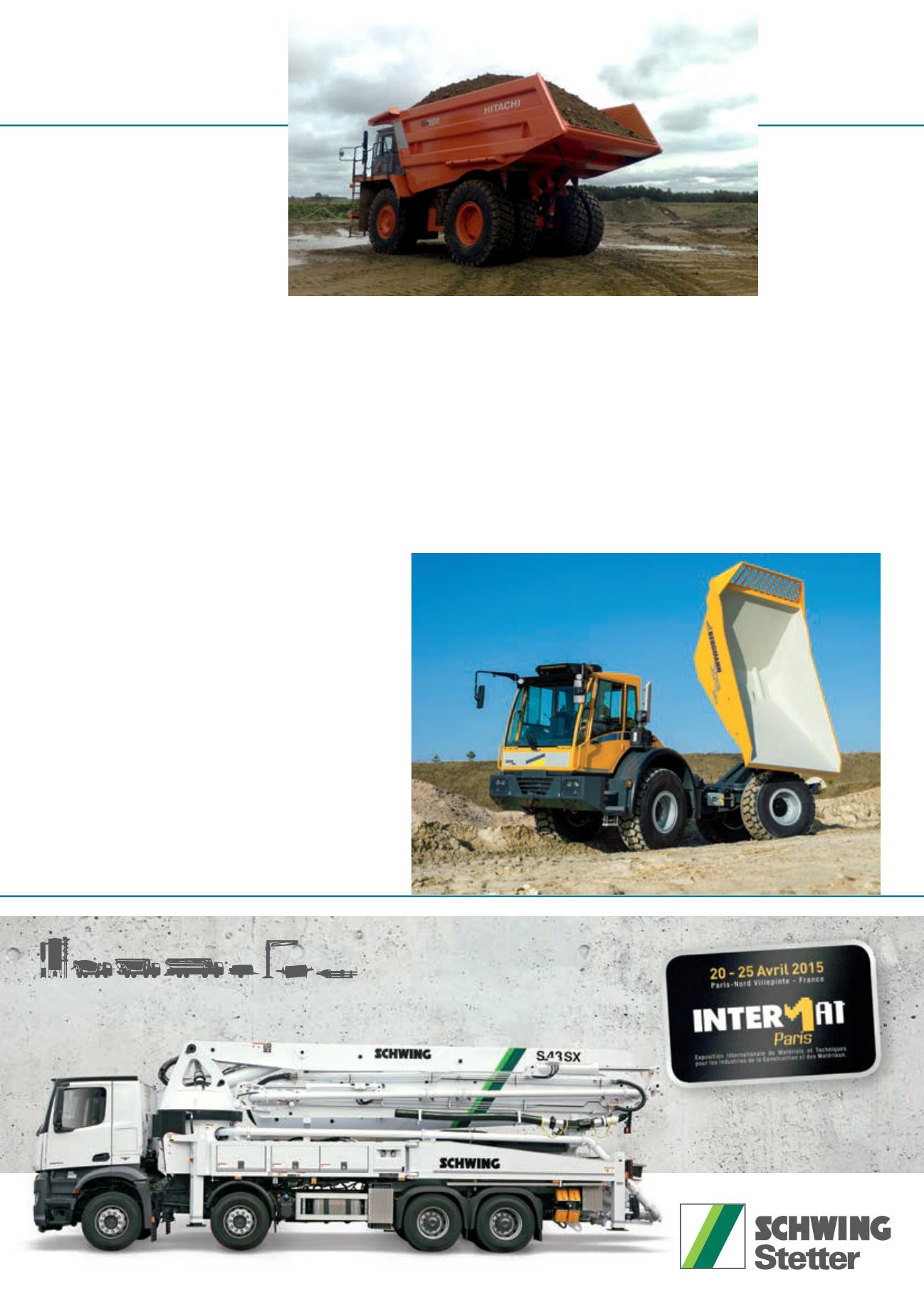

RigidHauler deal

Hitachi Construction Machinery is one of a number of

manufacturers offering rigidhaulers as part of its range.

It has suppliedBaltic energy companyEesti Energiawith11of

its EH1100-5models for use on a shale extraction operation at

theNarva quarry, near theRussian border.

Hitachi has supplied the haulers from its factor inCanada. It

had to prove its equipment could carry a nominal payload of

63.5 tonnes as part of the deal inEstonia.

The project included a calculation of the capital cost of the

machine and a guaranteed buy-back after a number of years.

At the opposite end of the earthmoving spectrum, Terex has

unveiled its Stage IIIB/Tier 4Final-compliant range of nine and

ten-tonne site dumpers.

Featuring 55kW JCB EcoMAX turbo-charged diesel engines,

the newTA9 andTA10models are said to offer users increased

fuel efficiencywithout anyexhaust after-treatment requirements.

The units are said to emit among the lowest emissions for

comparable payloads, as well as delivering a lower cost of

operation and efficient cycle times.

Among their key features are Liquid Crystal Display (LCD)

dashboards, complete with hour meter, coolant temperature

gauge and fuel level readout.

Early warning alerts help to prevent costly downtime and

enhance operator safety. In addition, a user readout panel

provides real-time machine information, while Engine Control

Unit (ECU) technology manages performance data to improve

reliability.

iC

SCHWINGGmbH

ϕ

Heerstrasse 9– 27

ϕ

44653Herne, Germany

ϕ

Tel.:+492325 - 987-0

ϕ

Visit us on the INTERMAT

Stand E6– E048

Recordbreaking engineering

Bergmannwill be releasing

its latest tipper truck, the

3012, at Intermat next month.

Hitachi has

supplied a

number of

EH1100-5 rigid

dump trucks,

to an energy

company in

Estonia.