39

PRODUCT SUPPORT

INDUSTRY FOCUS

OCTOBER 2014

ACT

Restoring an old crane is

one thing but restoring a

badly damaged new crane

was quite the challenge

for Certified BoomRepair.

crane structure itself including thebooms

andboom lift and extend cylinders is

incredibly toughand sufferednodamage.”

CertifiedBoomRepairhada strong

relationshipwith the company that bought

the salvaged crane.

“They trustedCertifiedBoomRepair to

provide the structural repairs andpeace

ofmind required to tackle aproject of this

size,” saidSmith.

Nuts to bolts

The repair and restorationprojectwas

deeply complex. It required complete

teardownof the engine and transmission,

complete rebuildof forward frame rails,

both cabs, counterweight assemblyand

re-wire to factory specifications.

“Every componentmounted to the frame

railshad tobe removed,”Smith said. “This

includesbrackets,wiring,motormounts

B

ack in2011, abrandnew

Link-BeltHTC8675wasbeing

delivered from the factory in

Kentucky to itsnewowner inTexas. But as

bad luckwouldhave it, the lowboy trailer

the cranewasbeinghauledongot intoan

awful predicament. It became stuckon

live railroad tracks.Withnowhere togo,

anoncoming trainwasnot able to stop in

time and struck the crane and trailer.

“Very fortunately, noonewashurt,”

saidMikeSmith, president,Certified

BoomRepair, Tampa, FL. “Although the

frame rails andvirtuallyall thehardware

forwardof the front outriggerboxwas

destroyed, aswereboth cabs, theLink-Belt

A trainwreck

Certified Boom Repair performed all the

straightening andweldingwork and then had

it third-party inspected and certified.

Surveying the damage, the

technicians and engineers

at Certified Boom Repair

realized that the crane could

be repaired.

transmissionmounts, andallwith the

notion that theyhad tobe re-installed

back to theway it cameout of the factory.

Countlesspagesof notes, pictures taken

andhoursof reverse engineeringwere

crucial to the successful rebuildprocess.”

The frame railsweremadeof 100,000

PSI yield steel. Theyhad tobe sent toa

specialist in theNortheast tobe formed to

the correctmeasurements.

“We trust themwithour steel breaking

for cranebooms aswell as frame rails,”

saidSmith. “Theprocessof forming the

steel accuratelywas critical to theprocess

andasusual theydidan excellent job.”

As forpartsneeded fromLink-Belt, he

said therewere some suspensionparts,

motor and transmissionmounts aswell

as electrical parts.CertifiedBoomRepair

also installednew suspension, tires and

steering componentson the crane and

provided supportwith the logisticsof the

certificationprocess.

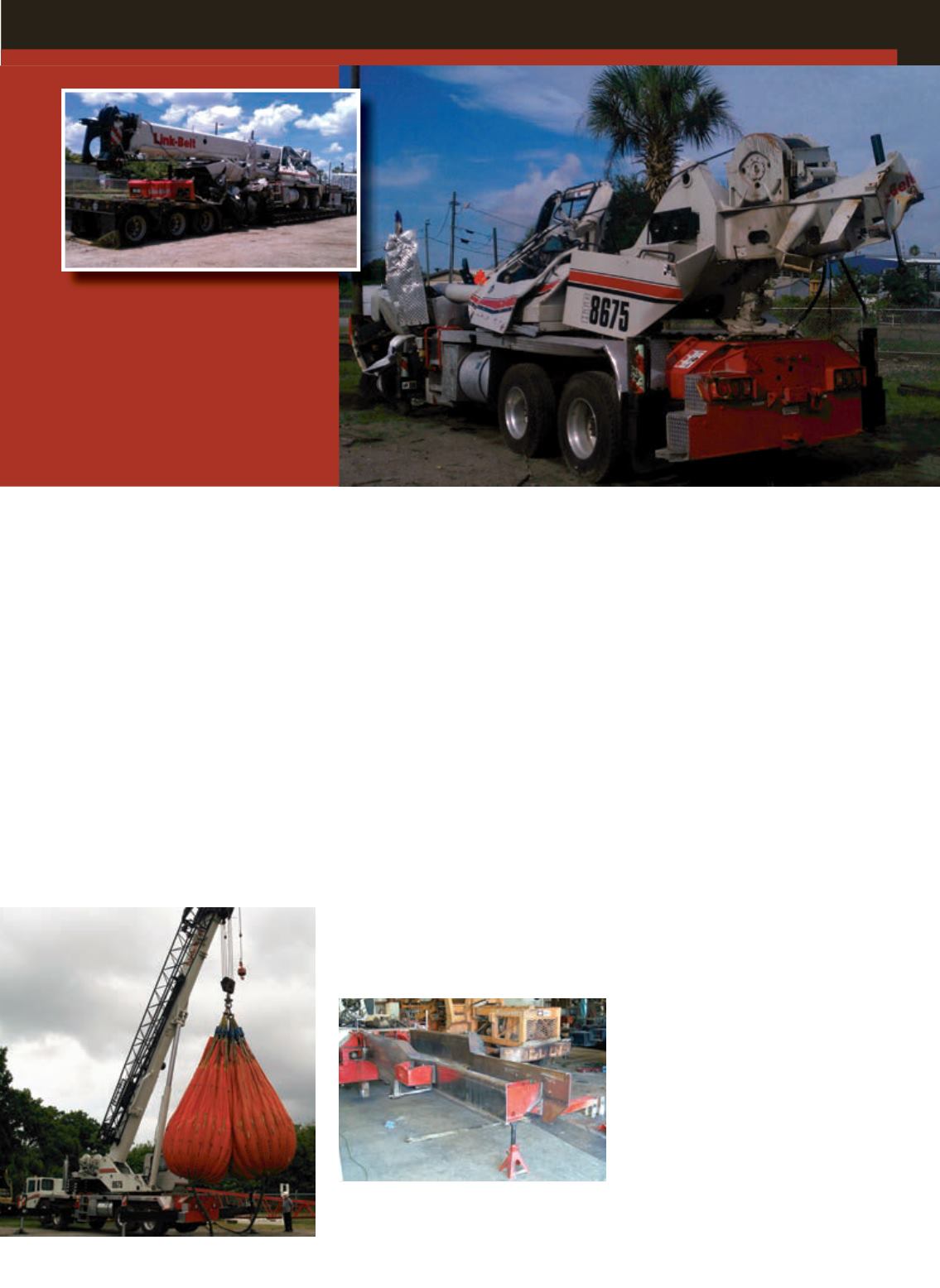

After the cranewas repairedand

restored, a third-party inspection, load

test and recertificationwas conductedby

DennisO’Rourke, founder andpresident,

NationalCraneServices,Orlando, FL.

“This crane is inamazinglygood

conditionandhandledall operatingand

load test requirements, includinga50-ton

lift, aswell as anywe’ve ever recertified,”

saidO’Rourke.

Formorephotosof the repair, visit

.

■

Thorough third-

party inspection

and testingwere

performed to

make sure the

cranewas able

to lift its chart

capacity.