University Lecturer,

Dr Techn Saku

Suuriniemi

It is already some time since you carried out this research. Were there any

other actions taken?

Yes, there was another master’s thesis on this subject.

Has there been further research on this in other universities after your

study?

No, I am not aware of other research on this subject.

Have there been technical developments that could change

the situation? Would the results be different if the tests

were repeated today?

No. The biggest issue was control of the reflection of the

waves. This reflection is a law of nature and we know the

behaviour of waves. There are no new means to control

those in job-site conditions.

Do you think this could change in future? Could

there be technology that makes this approach

possible in practice?

At this moment I do not believe so. I think there would

have to be a new, different basic principle. We should

see the situation from the target’s

point of view. For example, if we

could create tension in the concrete

just around the reinforcement

bar, it would effectively break that

connection and the concrete would

lose its strength.

deep in the material, with surface

wetting alone being insufficient.

Another challenge was that high

moisture levels causes a high

power density on the surface.

When the material is dry, the

radiation penetrates deeper but

the power density is lower.

IN ACTION

Microwaves move in principle

like waves on water. We know

how waves reflect in a swimming

pool when conditions are

suitable, and microwaves can

also be reflected, depending

on the material. The problem

here is that a magnetron can

be damaged by such reflected

radiation, even though it had

just emitted that very radiation.

Steel causes a much stronger

reflection than concrete.

In suitable circumstances,

reinforcement bars may carry

the waves further and when the

power level is sufficiently high,

there may be sparking around

the steel.

Not all concrete is the

same. Cement may be

similar, but the sand

and gravel used can

consist of different

minerals and this

can change the

behaviour of

the microwave radiation on the

surface of the concrete.

How the radiation is absorbed

in the object depends on a

number of factors, with the

presence of rebar being one of

the most important ones. The

above mentioned type of concrete

is another. The positioning of

the magnetron in relation to the

object block is also important,

especially the distance between

the block and the magnetron and

the direction of the radiation.

In jobsite conditions it is hard

to get perfect positioning. If

safety issues are in control, there

still is the reduced efficiency.

This creates an issue with power.

We want high temperature in a

small area, this means we have to

bring more power in the material

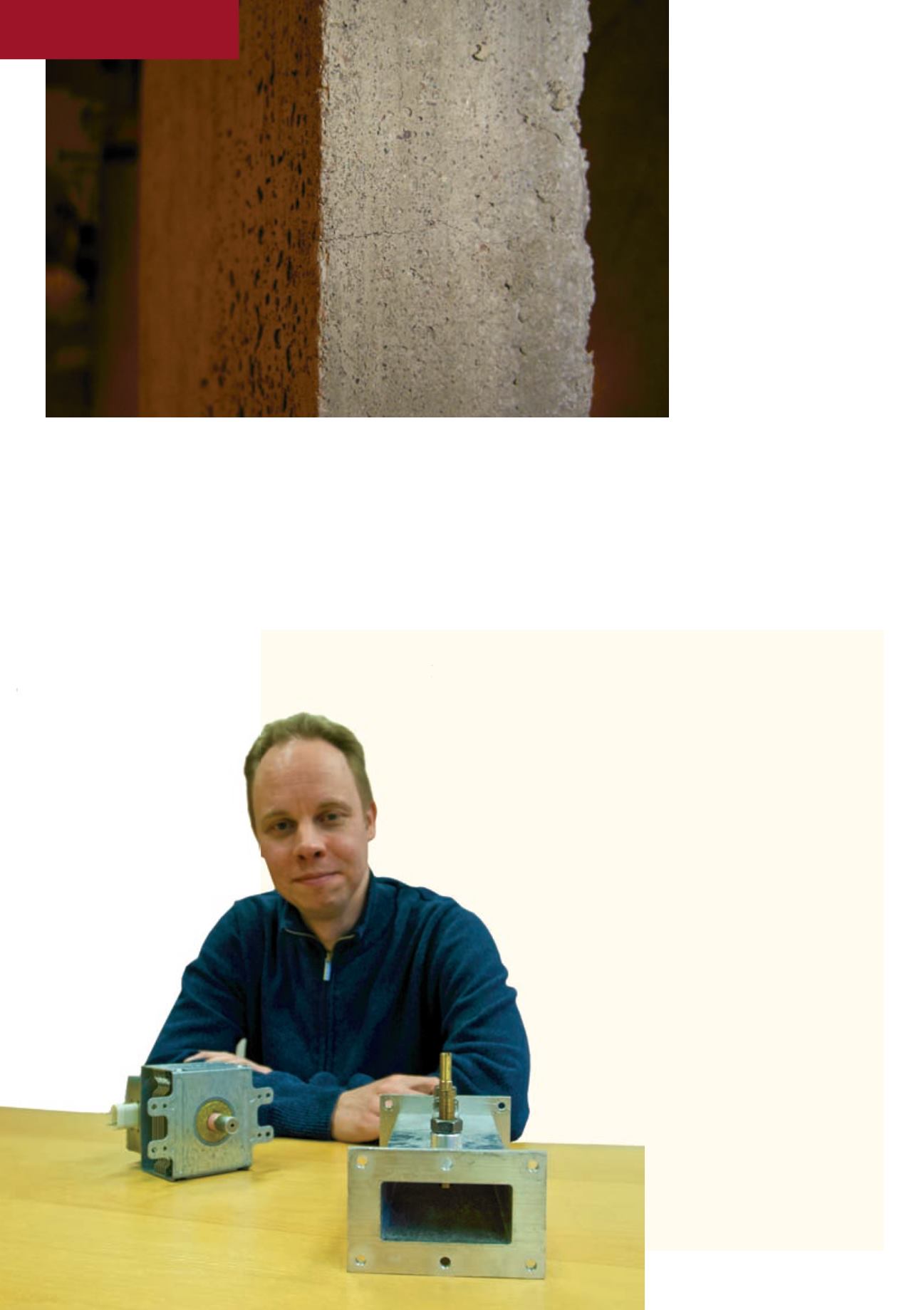

A thinner

concrete

slab with

a clean

fracture and

hot (thus

dry) areas

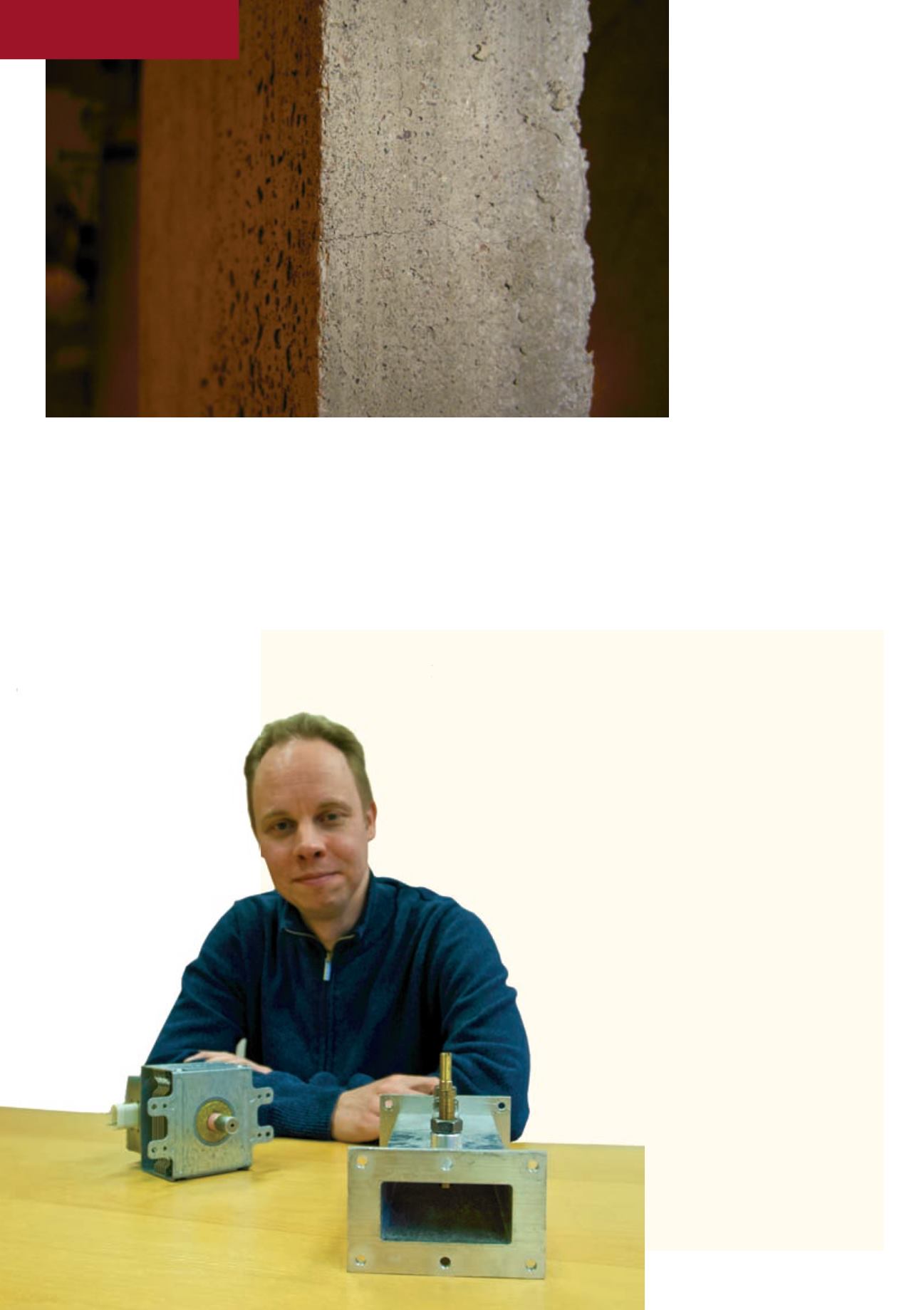

Author Dr Saku Suuriniemi with some of

the equipment used during thr trials

than what leaks out. The target is

massive and the required power

is high. Poor efficiency makes the

power requirement even higher.

To make the situation even

more complicated, the heat

vapourises the moisture and this

makes the heated area expand

faster.

The test proved clearly that

concrete strength was reduced

after microwaving and visible

cracks were also created. The

calculations were correct and

the theory was proven correct.

The disappointment was that

the reaction in concrete was

slow. Heat should be generated

faster. From the test results it

was estimated that in job site

conditions, the power would

have to be in the order of

hundreds of kilowatts and that

naturally there would be practical

difficulties encountered as a

result. For example, radars can

handle that power but there the

circumstances are very different.

The final conclusion of the study

was that the theory works as

predicted but a practical solution

is too inefficient.

■

10

NOVEMBER-DECEMBER 2013

d

&

ri

NEWS REPORT