41

d

&

ri

JULY-AUGUST 2013

V

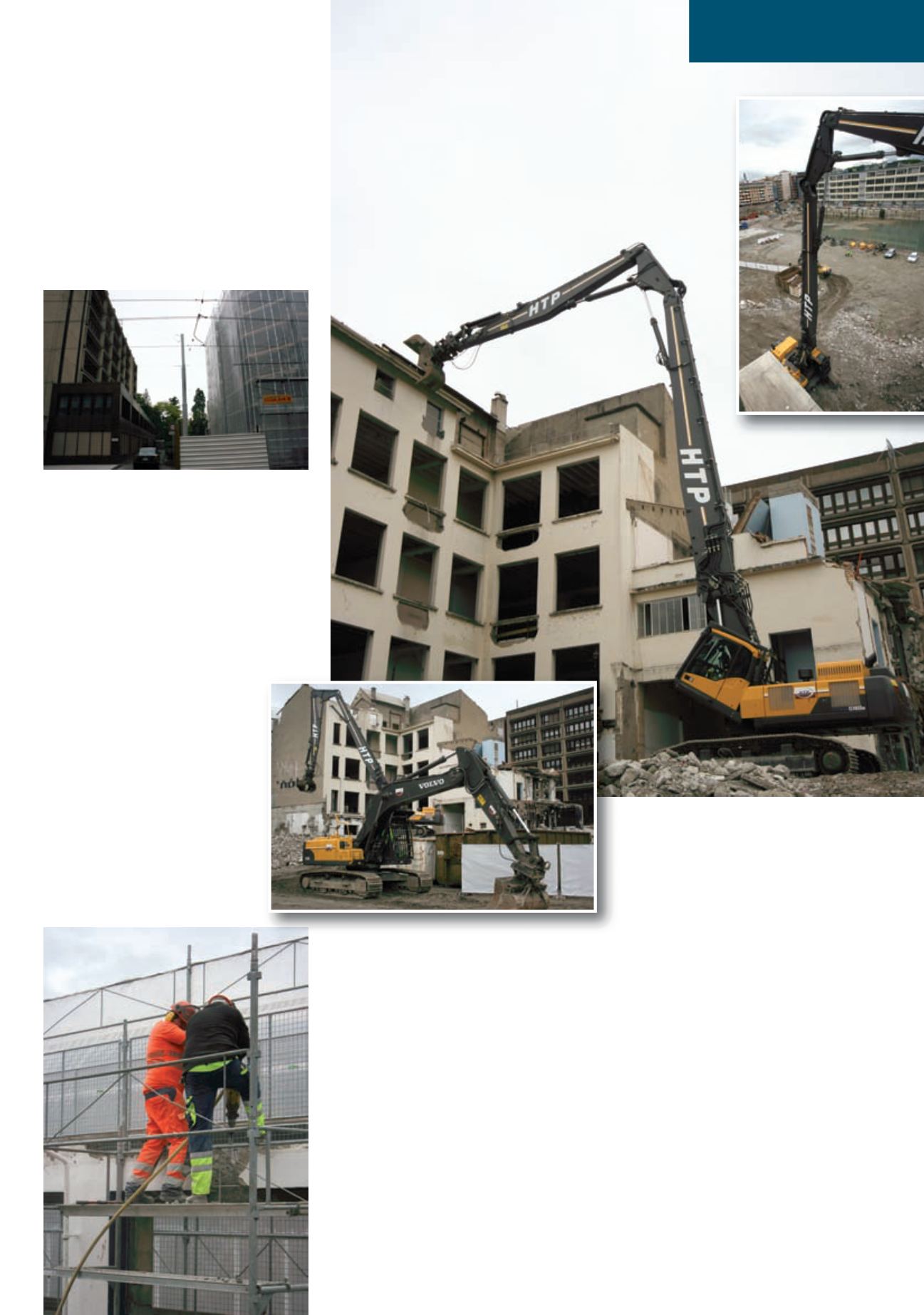

olvo has recently delivered the first

of its Stage 3B/Tier IV Interim

compliant EC480D Series machines

to Swiss contractor HTP SA, based in Vernier,

just outside Geneva, where it will be put to

work on sites around that city. It first moved

onto a site that would allow the operator to

gain experience on a machine its

size (HTP had previously owned a

smaller 30 tonne Hitachi high reach)

and has now recently completed

demolition work to clear the site of

a former government office block

on Geneva’s Rue de stand 20 to

make the site available for future

redevelopment.

The 480D provides a reach of

27 m (88.6 ft) and has an operating

weight of 61.2 tonnes. It has a

maximum forward reach of 16 m

(52.5 ft), can carry a 3 tonne tool

(including any quick coupler) and

can operate over the tracks to a maximum

angle of 15 degrees. The new machine

comes as standard with bucket and boom

cylinder guards, slewing ring protection,

frame mounted FOG guard, micro-mesh

screens on doors and engine cowling, bolt-on

impact protection system, enhanced under-

guarding, full length track guards, a Total

Moment Indicator, a hydraulically retractable

undercarriage for easier transport and a 125

mm (7 inch) camera on the high reach boom

for better visibility and safer operation.

With a total volume of 2,000 m

3

(70,630

ft

3

), the mixed 3 and 2 storey L-shaped

structure, built largely of concrete and brick,

is in close proximity to a live road at the

front and another modern office building to

the side. This required the construction of a

Swiss first

for Volvo

D Series

IN ACTION

Swiss contractor HTP is the first European company to

put Volvo’s new D Series high reach to serious work

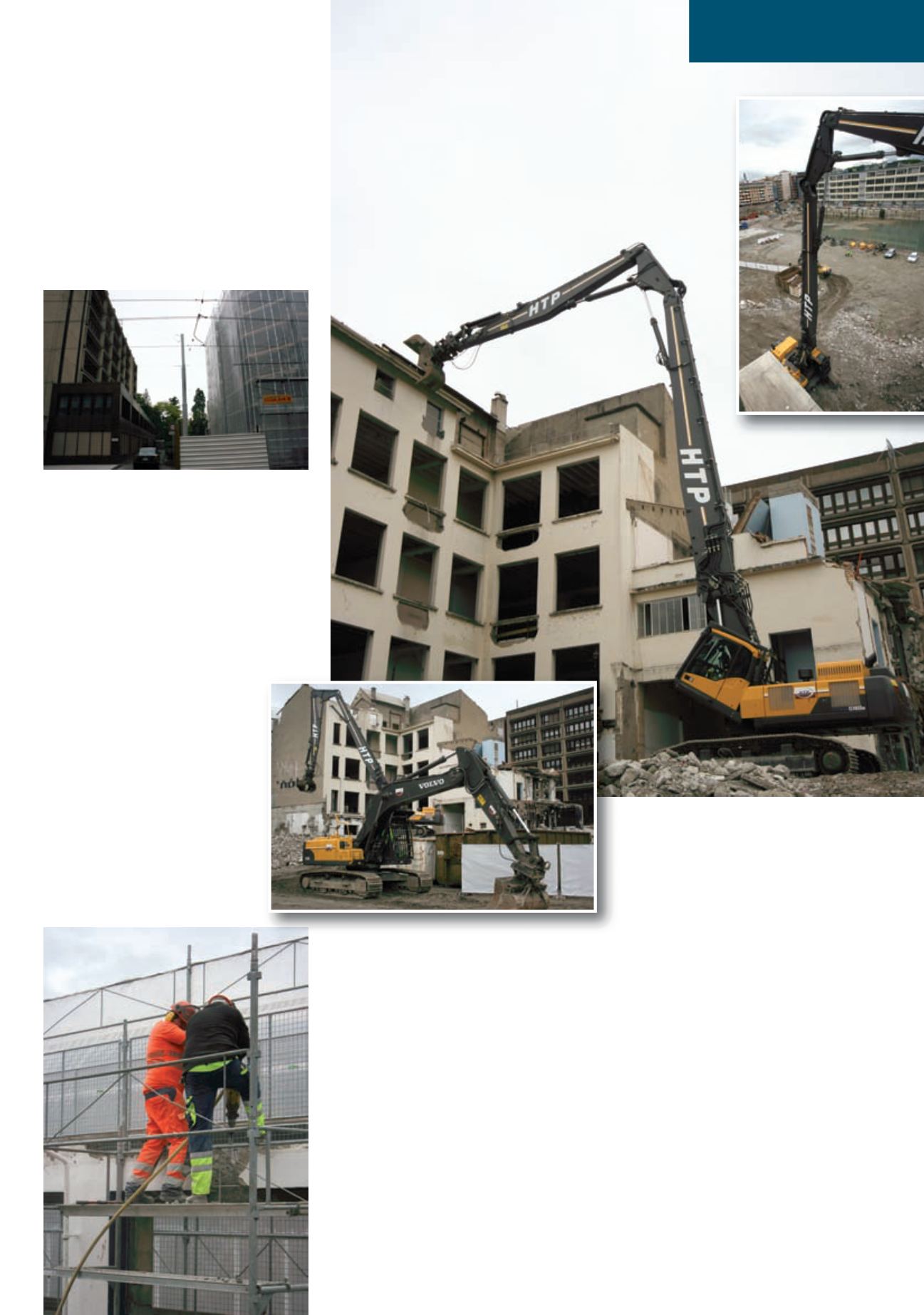

A scaffold protection structure was required on the

front of the office block to protect passers-by from

falling debris

scaffold and screened protection system to

ensure that no demolition debris could fall

outside the site and cause damage. Demolition

of the front and side facades is being carried

by HTP personnel using hand tools, with

the high reach being employed at the rear of

the structure where it can carry out selective

demolition in safety.

Work began on the site in early February

and was expected to be completed by early

June. All demolition waste arising from

the demolition was crushed on site by the

company’s RubbleMaster RM80 tracked unit,

and either used on site as fill for forthcoming

construction or transported away for use

elsewhere around the city.

HTP was formed by Yves Huguenin 15

years ago, and the company has grown over

that time to employ more than 70 personnel,

making use of a 24 machine fleet, which is

largely made up of other Volvo machines of

varying sizes. The high reach is the biggest

machine in the fleet and according to Yves,

will allow the company to tender for contracts

that were previously out of its reach.

■

The front façade of

the building has to be

demolished by hand to

ensure safety

The EC480D HR is, to

D&Ri’s knowledge,

the only production

high reach currently

available with a Stage

3B compliant engine

The new machine joins an equipment fleet

that is 80% Volvo