34

SITE REPORTS

JULY-AUGUST 2013

d

&

ri

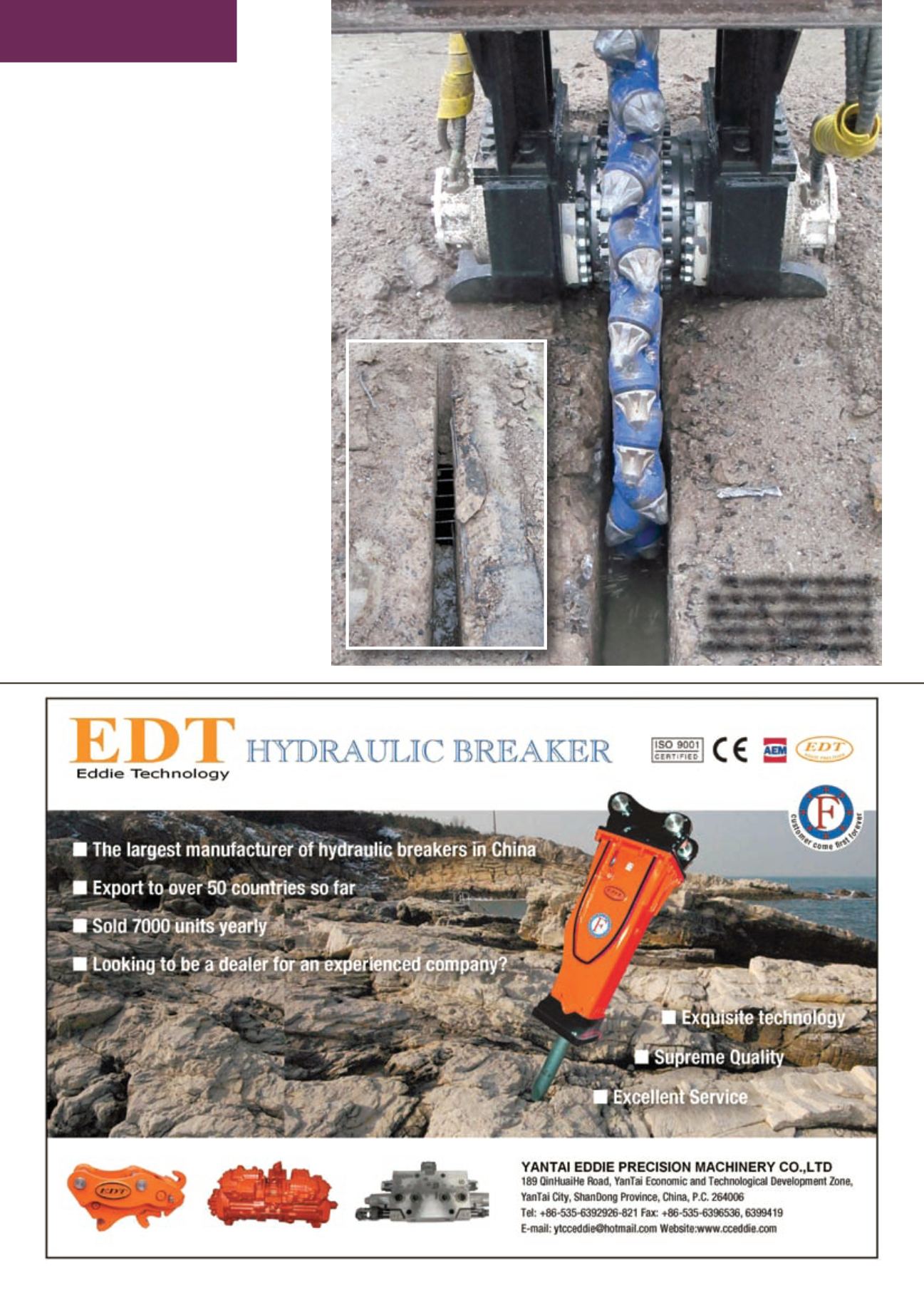

special heavy duty version of the cutter wheel

with very close pick spacing. Demcon fitted

a water spray dust suppression system using

the unlimited water supply from the harbour

and the resulting absence of dust allows other

operations to be carried out in close proximity

to the cutter wheel, speeding up the overall

demolition and construction process.

OPEN MINDS

Although originally designed for shallow

trenching applications, Anders Ståhle,

managing director of SMC, Sweden, was one of

the first equipment suppliers to recognise the

potential for the cutter wheels in demolition

applications. He was aware of the importance

of speed at this project and introduced the

cutter wheel to Demcon.

“The new cutting wheel is a safe and

efficient demolition tool. There are strict

requirements preventing us from allowing

concrete to fall into the water. The cutter wheel

is great because we can use it to cut through

concrete and rebar in a controlled manner.

Reliability has increased and consequently it

gives us better performance,” said Andreas

Svensén, production manager major projects,

Skanska Sweden.

Klaus Ertmer, the managing director of

Erkat said, “if we hadn’t listened to the needs

of our customers and worked with them to use

products like the cutter wheel, we would miss

out on many opportunities to provide unique

solutions to some of the most interesting

challenges facing demolition contractors.”

■

The resulting clean cut through

the slab allows lifting chains to be

fitted and the remaining rebar cut

by torch or by a breaker, with the

sections then removed for recycling