26

JULY-AUGUST 2013

d

&

ri

EXCAVATORS

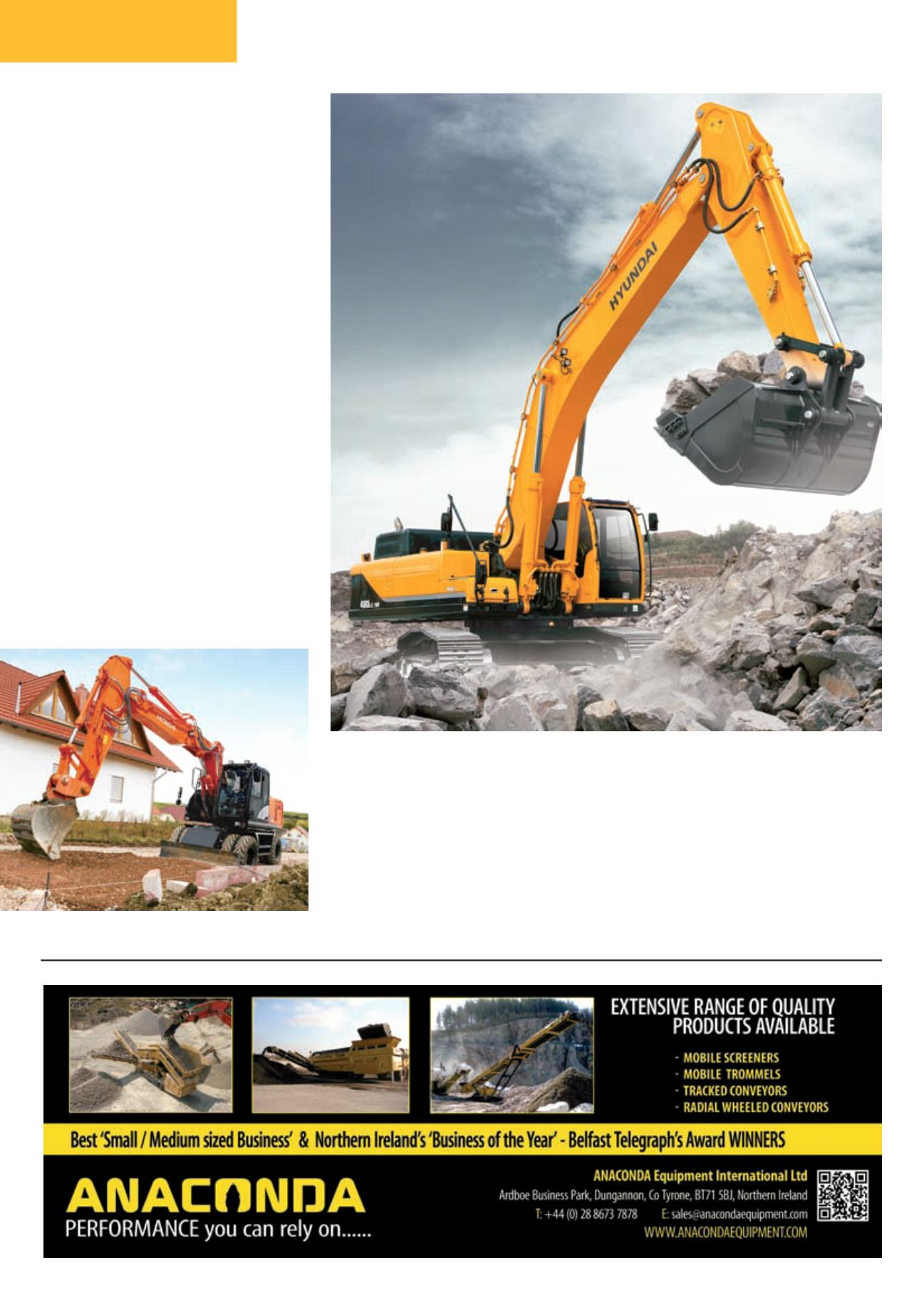

Hyundai’s latest generation

of excavators is the Robex

9A series, which feature a

new ergonomic cab design

as well as the latest

low emission engines as

required in Europe and

the USA

This year has seen Hitachi update its range of wheeled

excavators

expect to see on some of its other excavator

models in the near future – components

suppliers to the industry are starting to offer

off-the-shelf packages that include similar

fuel-saving elements.

Bosch Rexroth’s new Virtual Bleed Off

(VBO) system for example, is designed to

provide just the right amount of hydraulic

flow to a hydraulic circuit. Not only does this

save fuel, but the company said it also makes

for more comfortable operation and faster

response.

Doosan has already adopted VBO for

its DX340LC-3 and DX380LC-3 Stage IIIB

compliant crawler excavators, where it is

branded as D-Ecopower technology. A 26%

improvement in productivity and up to

12% in fuel savings is being claimed for the

electronic pressure-controlled pump and

closed centre hydraulic system, depending on

the mode selected.

HYBRID FUTURE?

Although it is early days now, hybrid

technology looks to have a place in the

excavator designs of the future. Clearly there

are competing technologies, and the market

will decide which is best. It may be that

different technologies work better in different

applications.

As a final note on the hybrid question,

Liebherr exhibited an interesting concept

machine at Bauma incorporating numerous

systems into a 40 tonne package. The R 9XX

concept crawler features both electrical and

hydraulic systems to capture and store waste

energy, and Liebherr says it would make a

160 kW diesel engine viable, whereas a

standard power unit for a 40 tonne machine

would normally be well over 200 kW.

As well as capturing slew brake energy,

Liebherr has devised a system to grab waste

energy used to lower the boom and stick.

Hybrids will become more attractive

options if fuel prices go up because fuel

efficiency will become a bigger part of the

equation when it comes to working out the

whole-life cost of a machine, and Liebherr’s

concept R 9XX demonstrates that there are

more areas on an excavator where waste

energy can be caught and re-used.

But as hybrids become more and more

available, it is always going to be a wise move

to weigh up the increase in purchase cost

against the fuel savings that can be achieved

to work out how soon the pay-back will come

(if at all).

■