22

JULY-AUGUST 2013

d

&

ri

EXCAVATORS

New Hidromek 50

tonne heavyweight

Hidromek has added a prototype 53.2 tonne excavator to its offering, the HMK 540

LC HD. The machine has been designed to operate on demanding sites such as large-scale

construction projects and quarries.

Standard equipment includes a 3 m

3

(106 ft

3

) bucket with a breakout force

of 29,900 kgf (293 kN). The maximum

digging depth is 7.1 (23.3 ft) m and the

maximum digging reach is 11 m (36.1 ft)

at ground level. Components include an

Isuzu AH – 6UZ1X engine and Kawasaki

hydraulic pump that offers an automatic

boost function, resulting in increased

lifting capabilities, lower cycle times and

higher breakout forces.

The cab is Hydromek’s Gen Series,

which is pressurised to prevent the

ingress of dust and dirt. A rear-facing

camera is standard and other features

include Opera Control System, a fully

automatic climate control system, a USB

port to play music, cool box and storage

compartments for personal items. The

new addition means Hidromek’s excavator

range now spans the 14 to 54 tonne

classes.

to weigh-up is how quickly buying such a

machine will pay-off. Yes, fuel consumption

is lower, but the extra on-board technology

inevitably means a higher purchase price.

This balance is something manufacturers

are highlighting. For example, speaking at

Bauma, Volvo Construction Equipment

president Pat Olney said any machine the

company produced would have to provide a

strong business case for its customers.

“Our focus is on fuel efficiency and

viability for the customer. We continue

to research hybrids and we have a lot of

experience in the group through Volvo Bus,”

said Mr Olney.

He added, “When we bring something to

the market, we want to make sure it is viable

for our customers. We think we have some

good ideas, but we’re not ready to talk about

them yet.”

The company exhibited a prototype hybrid

wheeled loader at the 2008 ConExpo-Con/

Agg exhibition, using an electric motor

alongside a traditional diesel. However, it

did not go on to put the machine into full

production.

HYDRAULIC ‘HYBRIDS’

This question of costs and benefits to the

customer is what prompted Caterpillar to go

down a different route in developing what it

describes as a hybrid. Although the dictionary

definition of ‘hybrid’ would imply a machine

with a combination of energy systems

on-board, Caterpillar takes a broader view

and defines its hybrids as anything that can

recover waste energy.

The company’s 336E H is a 36 tonne class

excavator featuring a hydraulic accumulator

to capture waste energy. But as Caterpillar

global product manager for large excavators

Ken Gray explained, there were other

departures from traditional excavator design

on the machine to cut fuel consumption.

“We have historically designed excavators

around a hydraulic pump speed. We have

designed this machine around a 1,500

rpm engine speed, which is the lowest fuel

consumption point. You compensate for

that with a larger displacement pump to get

all the hydraulic power you need, and you

electronically control that to make sure you

don’t lose performance and response."

“Then we have the ACS adaptive control

valve, which is there to optimise the flow

that is available. We need to put hydraulic oil

where we need it, when we need it in exactly

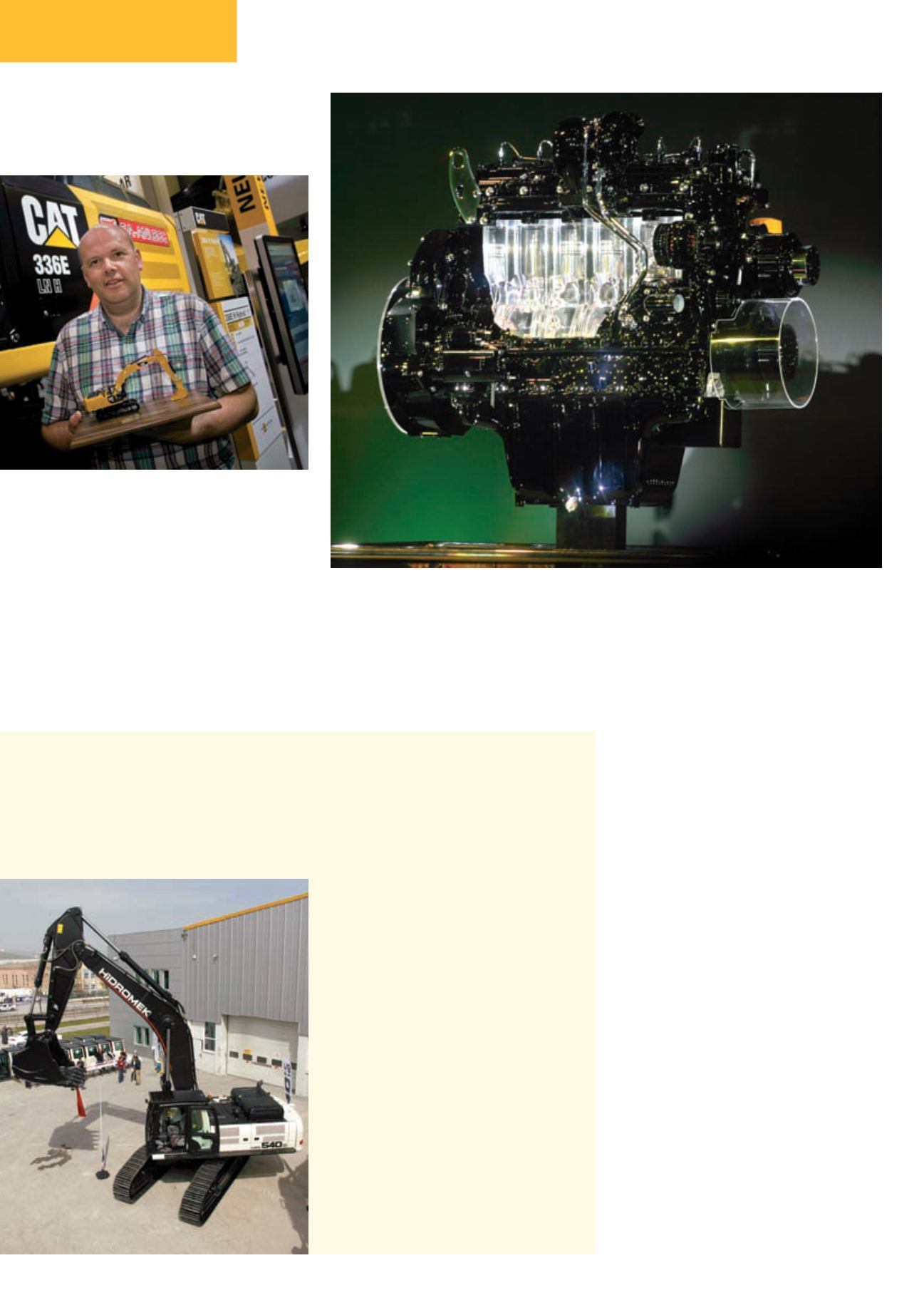

JCB recently launched the new Ecomax 672 diesel

engine for its JS330 and JS360 excavators – the first

6 cylinder diesel it has ever produced. Initially it will

only be available for developing markets

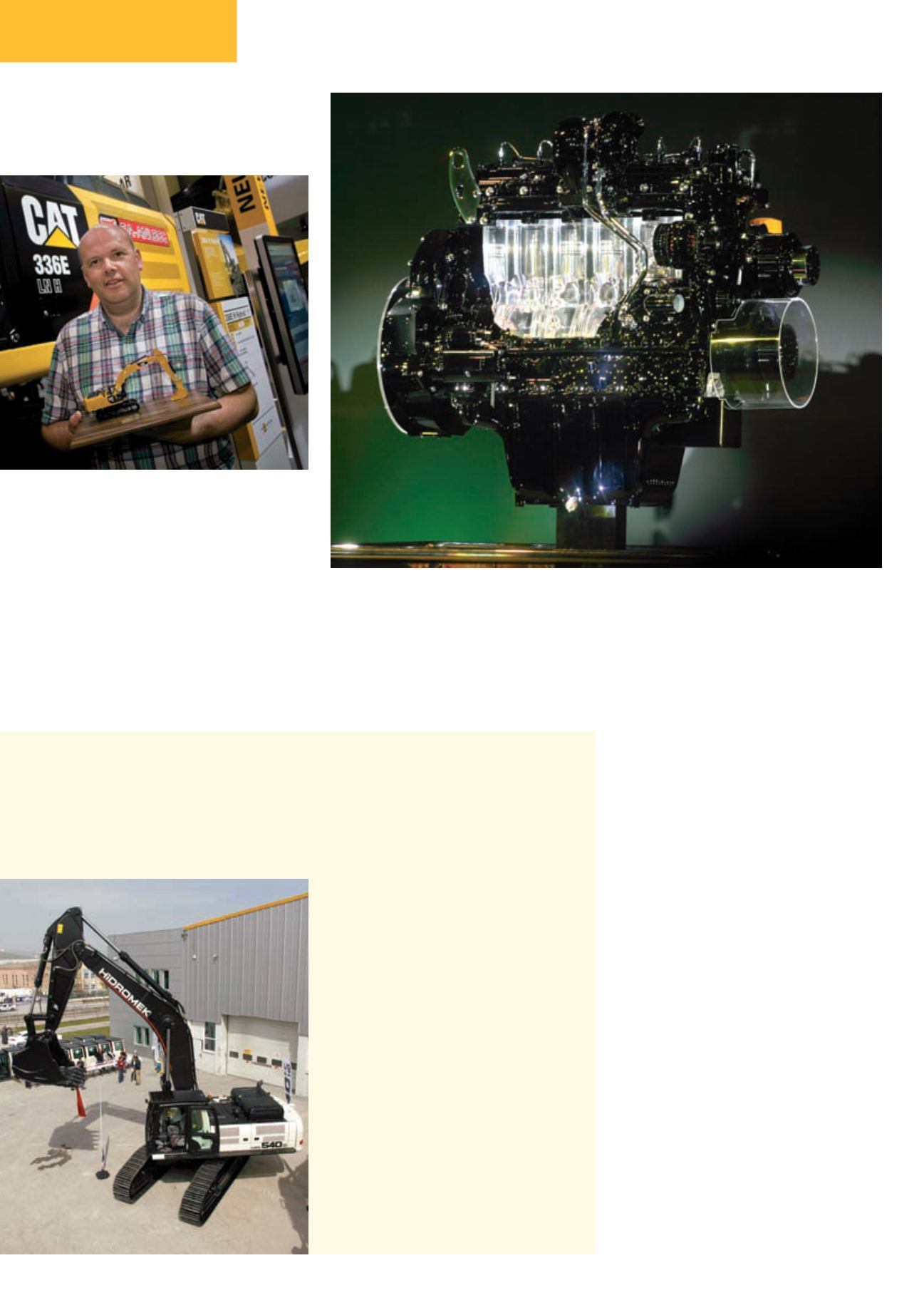

Sten Antonsen, owner of Norwegian contractor

SA-Anlegg took delivery of Caterpillar’s first 336E

H excavator. The order was placed just two days

after the machine’s launch announcement in October

last year, months before it would be commercially

available

>

25