30

SITE REPORTS

devastated that New Zealand city).

As is normal in demolition projects, access

to the site is being strictly controlled, with no

access permitted for unauthorised permits – it

does have to be said, however, that the owners

of the building are often to be seen on site in

normal day-to-day clothing, ignoring PPE

requirements. This is one feature of working

in the region, explained Rob, that GTS has

had to become accustomed to, and is just one

of a number of local conditions that jibe with

working practices encountered in western

Europe for which allowance has to be made.

The BurJuman II structure was totally

closed before work commenced, with ECC

constructing a temporary boundary wall

between it and BurJuman I shopping area as

the latter side of the mall is to remain open

to customers throughout the period of the

demolition and rebuild. In addition, the main

contractor isolated all services to the structure

prior to GTS coming on site.

There was a substantial requirement for

temporary access in the form of loadbearing

decks and gantries, and structural support

back-propping at numerous locations across

the site. Specifically this included scaffold

birdcage access to rooflight locations for

removals works to be carried out, a scaffold

surround for the plant room for demolition

purposes, scaffold crash deck and screw jack

propping to the soffit of the overhanging slab

beam formation in the roof demolition area.

Back propping is required from the basement

to ground level and to the soffit of the first

floor, and GTS had to make a scaffolding box

chute from the third floor to the second floor

and on down to the first floor level for efficient

material transfer through the building.

The most notable scaffold structure on the

site was an engineered bridge between the

front and rear ‘wings’ of the mall arranged

around the central atrium, which have different

roof heights. The original plan called for the

excavators that would break the roof slab to

be lifted up by the tower cranes and switched

from one to the other. In the event, this was

not possible and GTS had to come up with an

alternative method of getting the machines

from one side to the other – hence the bridge.

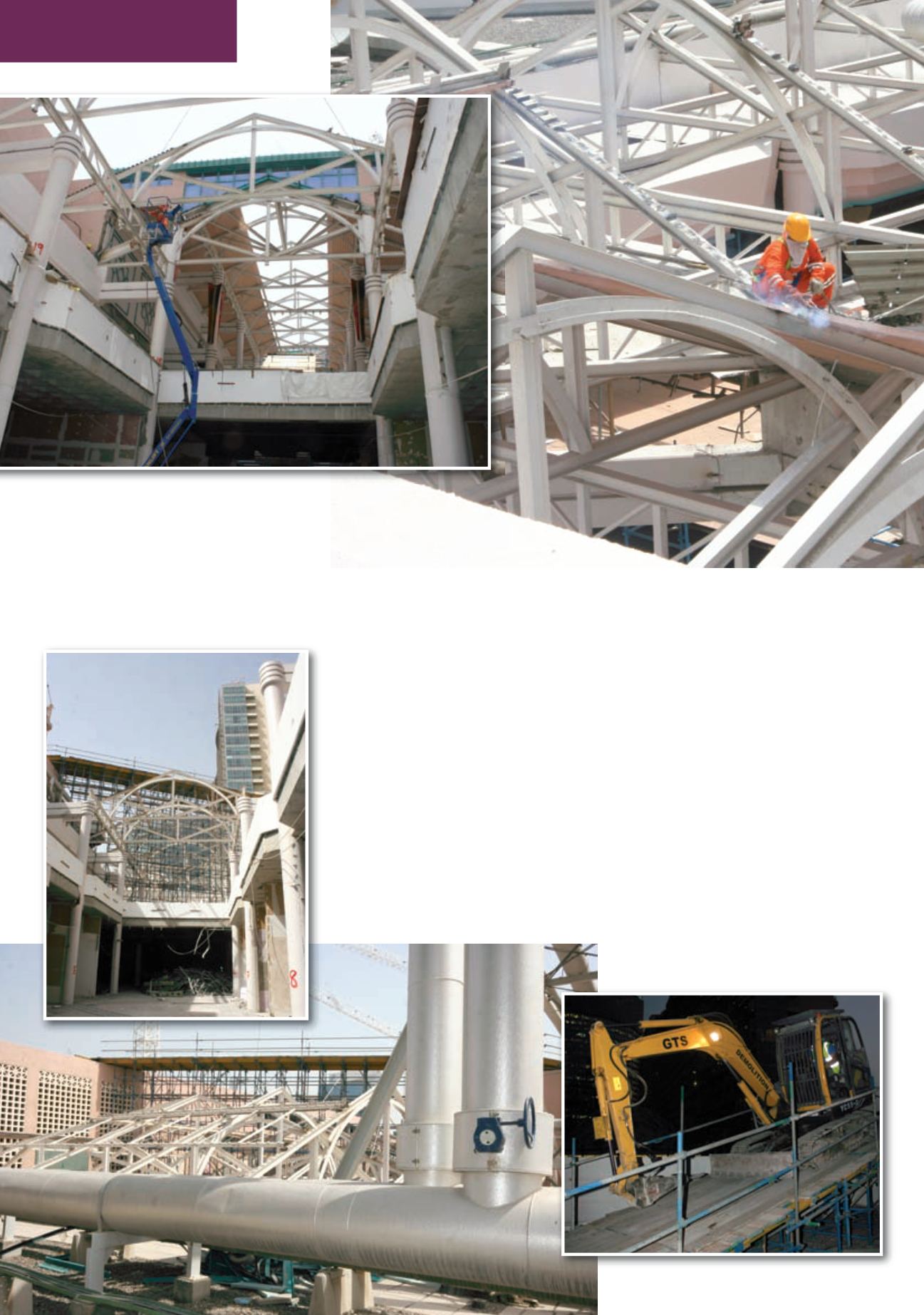

Workers cutting

the beams to allow removal of

the steel structure of the atrium roof

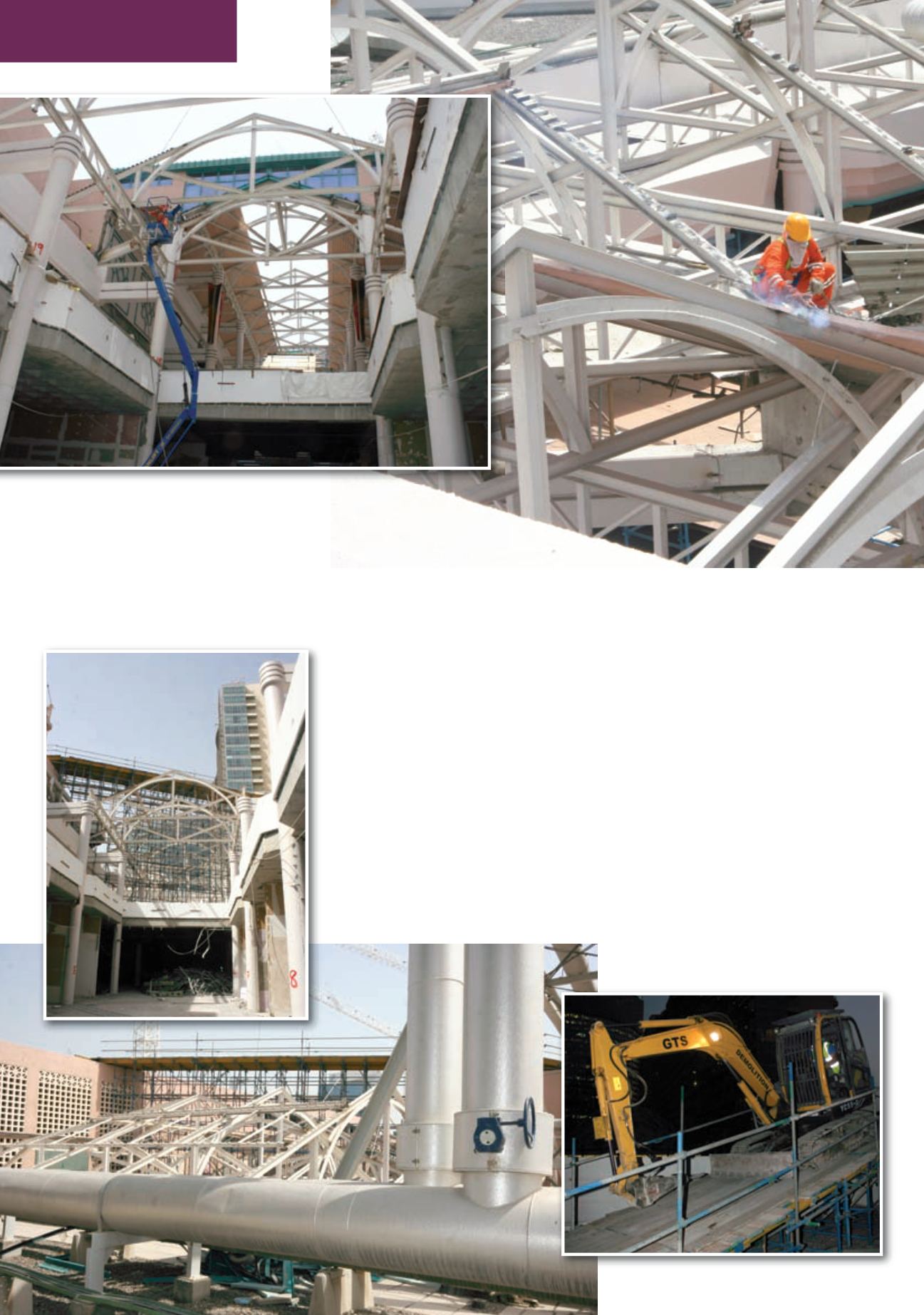

An engineered scaffold bridge has had

to be built to allow midi excavators to

cross one roof level to the other

JULY-AUGUST 2013

d

&

ri