27

SEPTEMBER 2013

ACT

I

n the crane industry, super heavy lift

cranes get a lot of attention, as well

they should. While your average crane

owner does not own a crane that can lift

in excess of 1,000 tons, much less 7,500

tons, the idea of a crane lifting this much

weight is awe inspiring.

Interestingly, the market for cranes in

this sector – those that can lift from 1,000

to 7,500 tons – is robust, with several

companies around the world producing

cranes that fall in the extra heavy lift

category. The attributes of these cranes

differ, with the manufacturers employing

varying designs and technologies to allow

these cranes to lift such huge payloads.

For the most part, demand for these

cranes is project driven, with nuclear

power plants, refineries and other

industrial applications comprising the

market. Many companies in this market

say their calendars are filled with work

stretching deep into 2014.

The Lampson International Transi-Lift

revolutionized the use of super heavy lift

cranes in the construction industry by

introducing the “over the top” method of

lifting. Transi-Lifts are one of the most

versatile and globally recognized cranes on

the market, says Kate Lampson, marketing

director.

“We are seeing a demand for heavy lift

cranes in the energy sector for new power

plant construction and refinery work,” says

Lampson. “We are also seeing a demand in

commercial construction.”

The Lampson Transi-Lift ranges

in capacity from 350 to 3,000 tons.

The Transi-Lift System is a patented

configuration that combines the heavy

lifting capacities of stiff leg derricks and

ring-mounted lift equipment with the

mobility of a conventional crawler crane.

“Easily adaptable to the lift requirements

of today’s heavy construction industry,

all Transi-Lift models boast precise

maneuverability, adjustable stinger length,

and multiple boom/jib combinations,”

Lampson says. “The Transi-Lift has the

ability to make multiple lifts on a jobsite

without having to disassemble.”

Lampson International has a new model

in production, the Transi-Lift LTL-3000.

It will feature joy stick controls in the cab,

hydraulic hoisting capabilities, a newly

designed enclosed engine compartment,

a 3,000-ton front crawler giving the crane

33 percent larger crawler capacity, a larger

boom cross section and an increase from 1

½ inch wire rope to 2-inch wire rope.

Project driven

Greg Augustine, national sales manager,

crawler cranes, Liebherr Cranes, Inc.,

says demand for super heavy lift cranes is

project driven.

“We are seeing an increasing interest

in cranes of this class; however actual

purchase is often dependent on a

successful project bid,” says Augustine.

“The sting of the last market downturn

is unfortunately still fresh in everyone’s

mind. Cranes in this class are a very

significant investment for any company,

even the very large companies that

typically own and operate these machines.

D.Ann Shiffler

reports

that the market for super

heavy lift cranes exceeds

expectations.

Despite the general uneasiness of this

market, we are very fortunate at Liebherr

to have been able to supply over 30

machines in this class globally.”

Liebherr’s largest heavy lifter is the LR

13000, a 3,300-ton capacity crawler. The

LR 13000 recently completed its inaugural

project at a petroleum refinery in Indiana.

Also from Liebherr is the LR 11360,

introduced in 2006, with a base capacity

of 1,488 tons. Both the LR 11360 and the

LR 13000 are equipped with derricks,

and ballast trays or wagons, in order to

maximize their lift capacities.

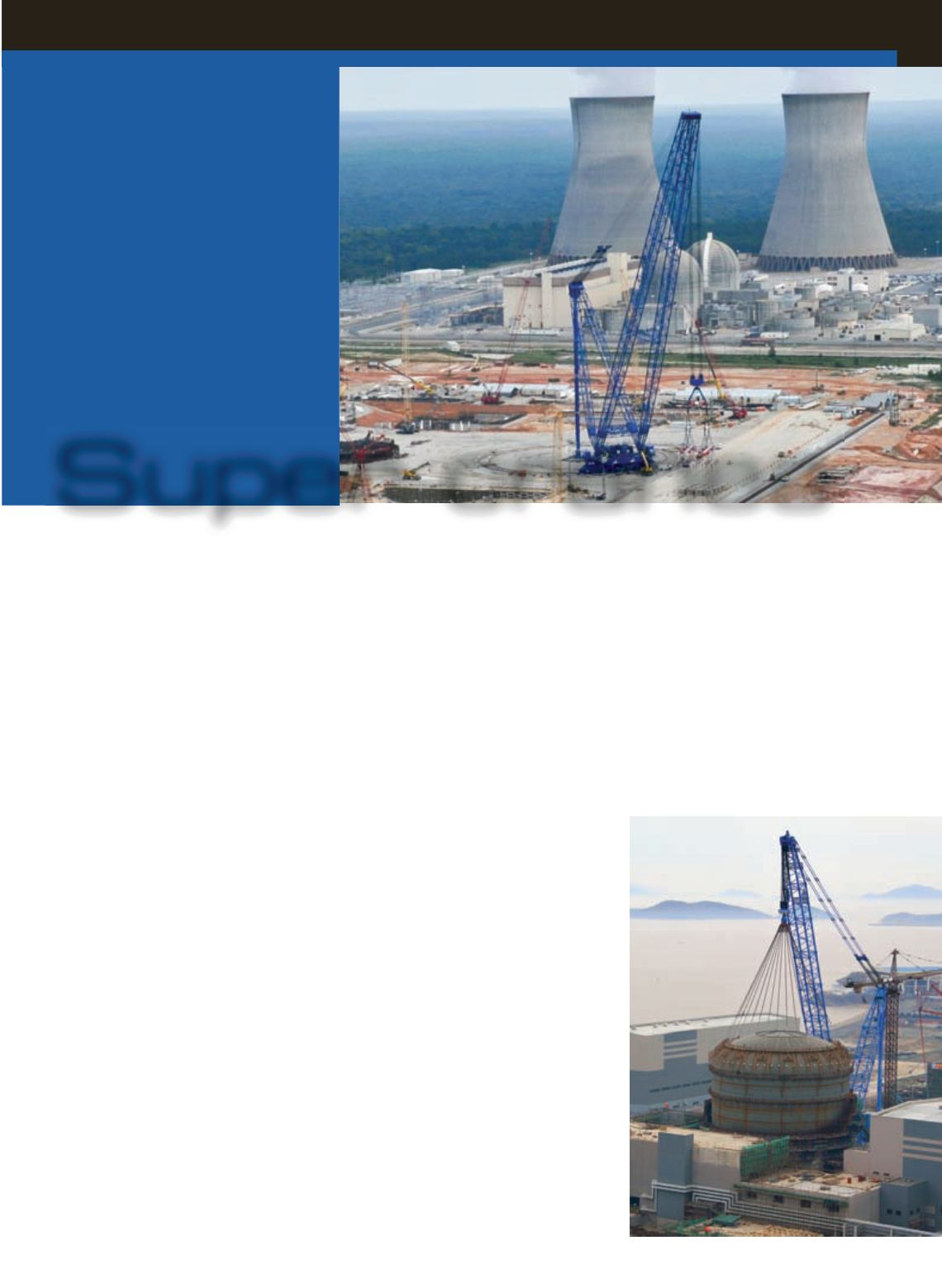

Super cranes

Bigge Crane & Rigging has

its two 7,500-ton capacity

AFRD units working in

Georgia and South Carolina.

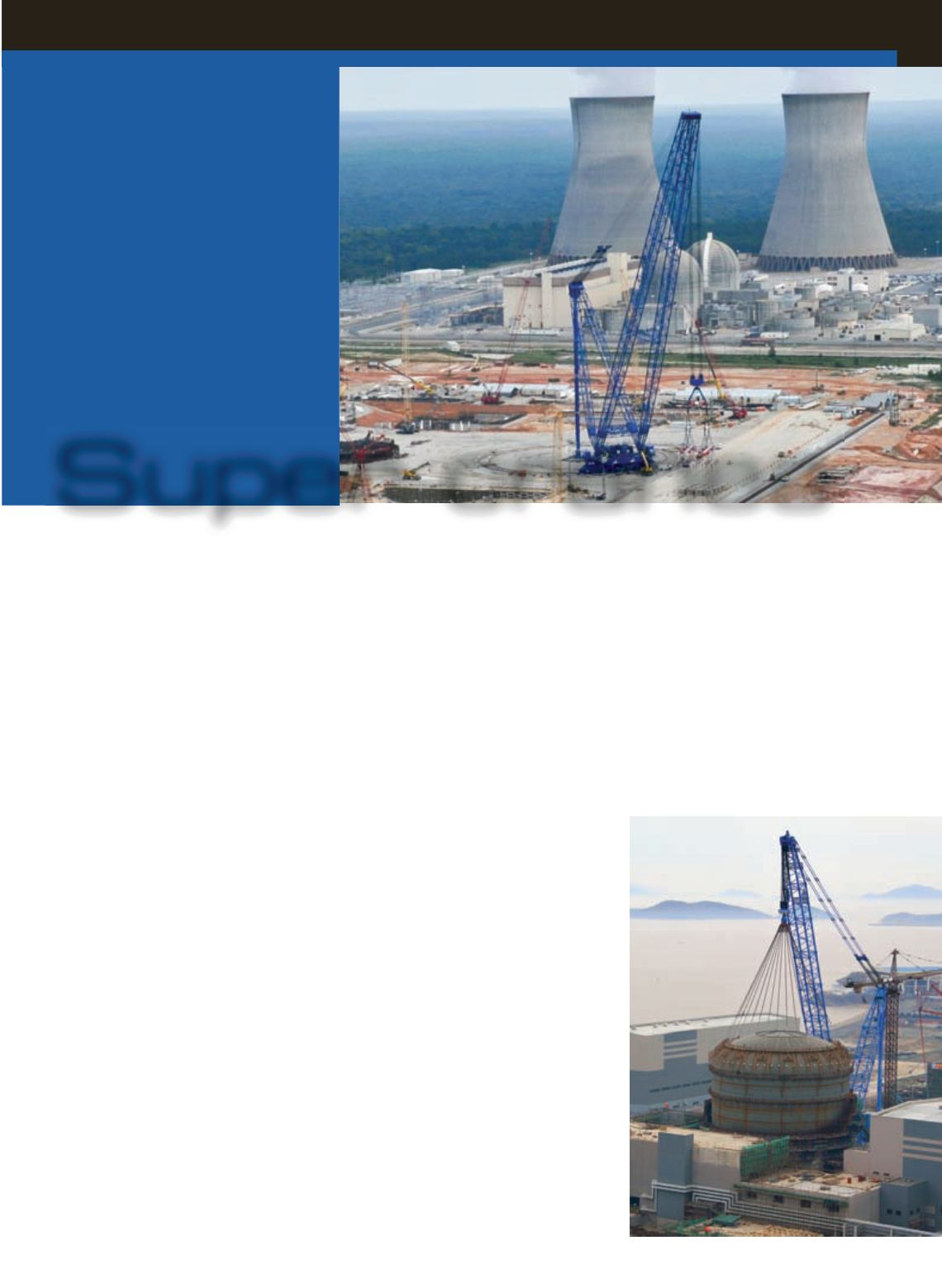

The Lampson Transi-

Lift has been a

mainstay in the super

heavy lift market for

more than 30 years.

Lampson International

has a new Transi-Lift

model in production,

the Transi-Lift LTL-

3000.

SUPER CRANES

PRODUCT FOCUS