30

ACT

SEPTEMBER 2013

PRODUCT FOCUS

SUPER CRANES

to liquefied gas. Of special interest to

Chunjo is the crane’s Variable Position

Counterweight (VPC) system, which

ranges from 28 feet fully retracted to

95 feet fully extended. It minimizes the

crane’s footprint and ground preparation.

Jerry Maloney, global product director,

says the market for heavy lift cranes is

strong.

“The market is still busy, and this is even

after the Fukushima Dai-Ichi Nuclear

Power Plant disaster slowed down the

expansion of new nuclear facilities

construction,” says Maloney. “Power plant

construction continues to grow, as does

work at fabrication yards for offshore

platforms and work in shipyards.”

Super AFRDs

Bigge Crane & Rigging entered the super

crane market in 2012 with its AFRD,

which the company claims is the world’s

largest capacity crane at radius. The ARFD

has a 7,500-ton capacity with 300-feet

of main boom and a 4,000-ton capacity

with 560-feet of main boom. Bigge has

produced two of the new models.

Gedge Knopf, major projects regional

sales manager, says that one machine is

working at Plant Vogtle in Waynesboro,

GA and the other is working at VC

Summer in Jenkinsville, SC.

Bigge declined to say whether more

AFRD units are in production.

The features that distinguish this crane

are high-speed performance machinery

for slewing, hoisting and booming,

exceptional capacity at radius, automatic

self-leveling, state-of-the-art safety

features, modular components for ease of

assembly and economical transportation.

Knopf says the market for the AFRDs

has been mainly for large, modular

construction.

“I also see the market for these cranes

growing over the next decade,” says Ryan

Parker, Bigge marketing manager. “We

still might not even know what industry

that may be, but as our world grows, so

does the need for super high capacity

cranes. It’s why we’ve continued work and

development of these cranes, as we look to

the future for their expanded use.”

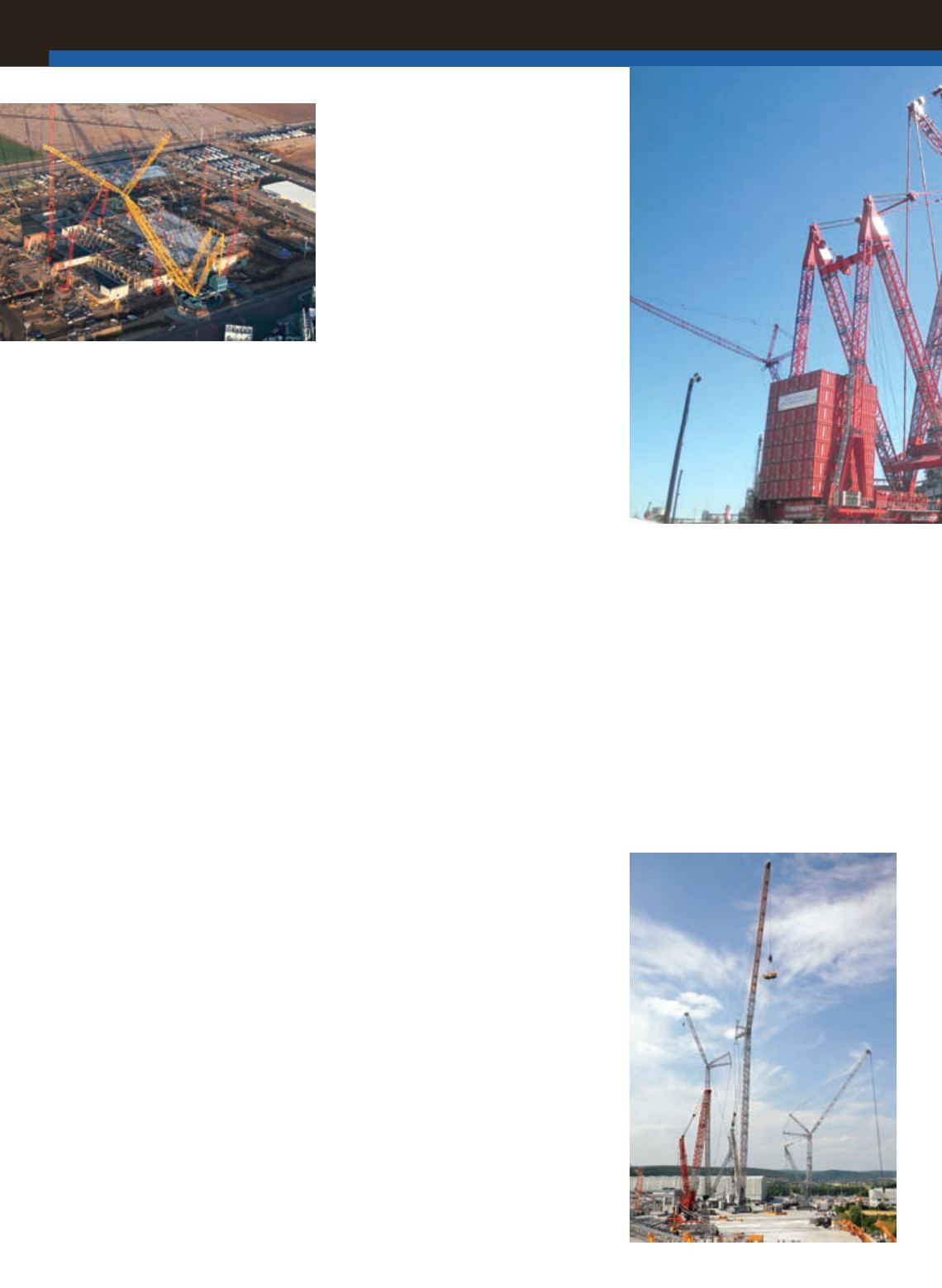

Mammoet Vice President Guus Stigter

says the market for his company’s PTC

cranes is impressive.

“We have one PTC 140 working at an

offshore fabricating yard in Ingleside, TX,”

he says. “It has been erecting sections of an

offshore spar, with each section weighing

about 2,500 to 2,800 tons.”

With a capacity of 3,500 tons, the crane

was set to complete work in Ingleside in

the fall and then move to another job.

Another Mammoet PTC 140 had been

working in the U.S. at a new steel mill

in Louisiana. That crane was moved to

a refinery along the Gulf Coast where it

removed an old coker unit and installed

a new one. The next job for the crane is

in Ponca City, OK to install coke drums

weighing about 500 tons each.

“Knock on wood, the market for these

cranes has been good,” says Stigter. “The

forecast looks very promising. There are

many projects on the books or in the

decision-making process to start moving

forward early next year. There are two

or three grass roots projects starting in

Louisiana and Pennsylvania. Most of these

are modularized and these lifts will exceed

1,500 tons. We feel comfortable saying that

there’s plenty of opportunity for these large

machines in the U.S.”

As well, the PTC 140 can be modified to

become the PTC 200, meaning that it can

be upgraded from 3,500-tons capacity to

5,000-tons capacity.

“In this case we are able to do a few

tricks, strengthening a few critical pieces

and recertify these cranes to 5,000-ton

capacity,” he says. “But at the same time,

it’s not about who has the biggest machine

it’s about the best fit for the job. That’s

how we look at it for our clients. It’s about

determining the right value for the job.”

Sources at ALE, which is based in

Staffordshire, United Kingdom, report that

the market for super heavy lift cranes is

In July, the Liebherr LR 13000 was

erected in its maximum lattice boom

configuration. The combination of the

120 meter main boom and the 126 meter

luffing jib produced a lattice boom system

with an overall length of 246 meters and

an overall height of 248 meters.

“continually active as clients see benefits

in new solutions offered by innovative

equipment in particular.”

ALE entered the super heavy lift

market in 2008 when it launched the

AL.SK190. The crane has the capacity to

lift approximately 4,816 tons and can be

relocated onsite fully rigged.

ALE has produced two of these cranes

that have worked around the world,

including at an oil refinery in Port Arthur,

TX.

In 2012, ALE announced it would build

a 5,600-ton capacity (5,000 metric tons)

AL.SK3050 to support construction

work at an industrial project in Brazil.

A Mammoet PTC 140 works at

an offshore fabricating yard in

Ingleside, TX. It has been erecting

sections of an offshore spar, with

each section weighing about

2,500 to 2,800 tons.

After working at its inaugural job at a

construction jobsite in Arizona, the Sarens

SGC-120 went to work in China.