53

LIFTING

SITE REPORT

DECEMBER 2014

ACT

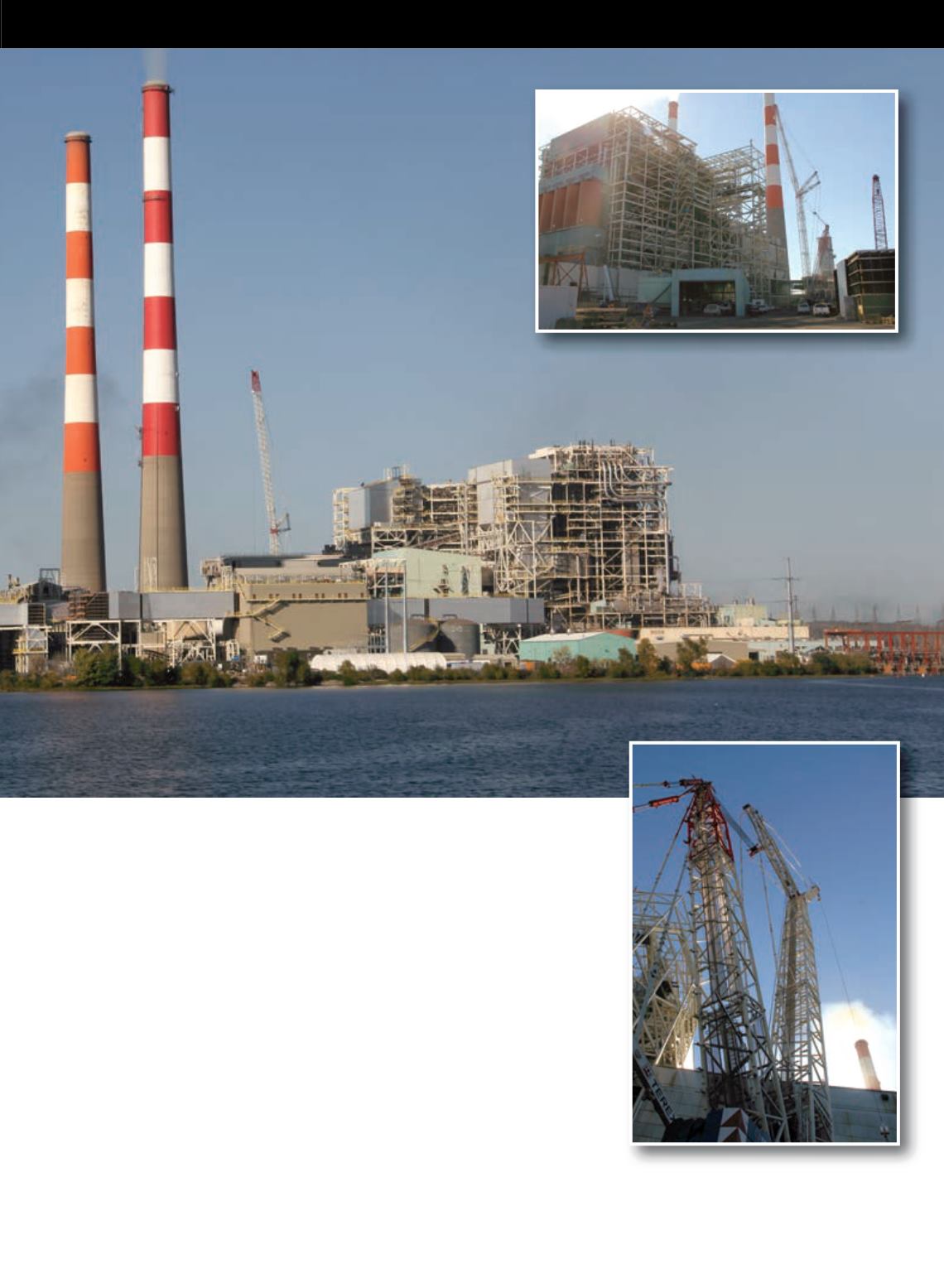

boom lengthof 215.6 feet, abackmast of

118 feet, 716,500pounds of counterweight

on thedolly, and364,000pounds ofmain

counterweight tomake the lifts.

Makingone-to-twopicks aday,

Mazzarese stressed itwas important not

to thinkof theSuperlift 3800 as a cycle

machine.

“This is aheavypickmachine,”he said.

“Itmight take sevenminutes tomake this

lift as opposed to twominutes, but you

have to think inbig terms. Thebigger the

machine, theygo slower.”

Working together

It took49 trucks to transport the crane

toLaCygne and four and ahalf days to

assemble it in late July and earlyAugust.

Once itwas built, itwashitwithwind,

thunderstorms and9 inches of rain in the

first fivedays on-site. After the initial

setback, theproject started rolling right

along. The cranewas projected to finish

uponNovember 15.Once it’sdismantled

andpackedup, theSuperlift 3800will

head to anotherpowerplant inNew

Mexico for its thirdofficial job.

“AmQuip strongly continues togrow

their projectwork, servingour customers

nationally,” said JimWorkman, regional

manager,AmQuip. “Weprovide a safe

and efficient lifting solution for our

customers. The Superlift 3800 is an

excellent addition toAmQuip’s fleet and

TerexCranes offers the fleet and service

we require.AmQuip andTerexhave a

long standingworkingpartnership in the

industry.”

Terex echoed that sentiment.

“Terexvalues thepartnership it haswith

AmQuip,” saidMarkPhillippi, director

of sales,NorthAmerica, Terex. “It’s great

to see aproject come together like this.

In the end, it’s about our customer’s

results.”

■

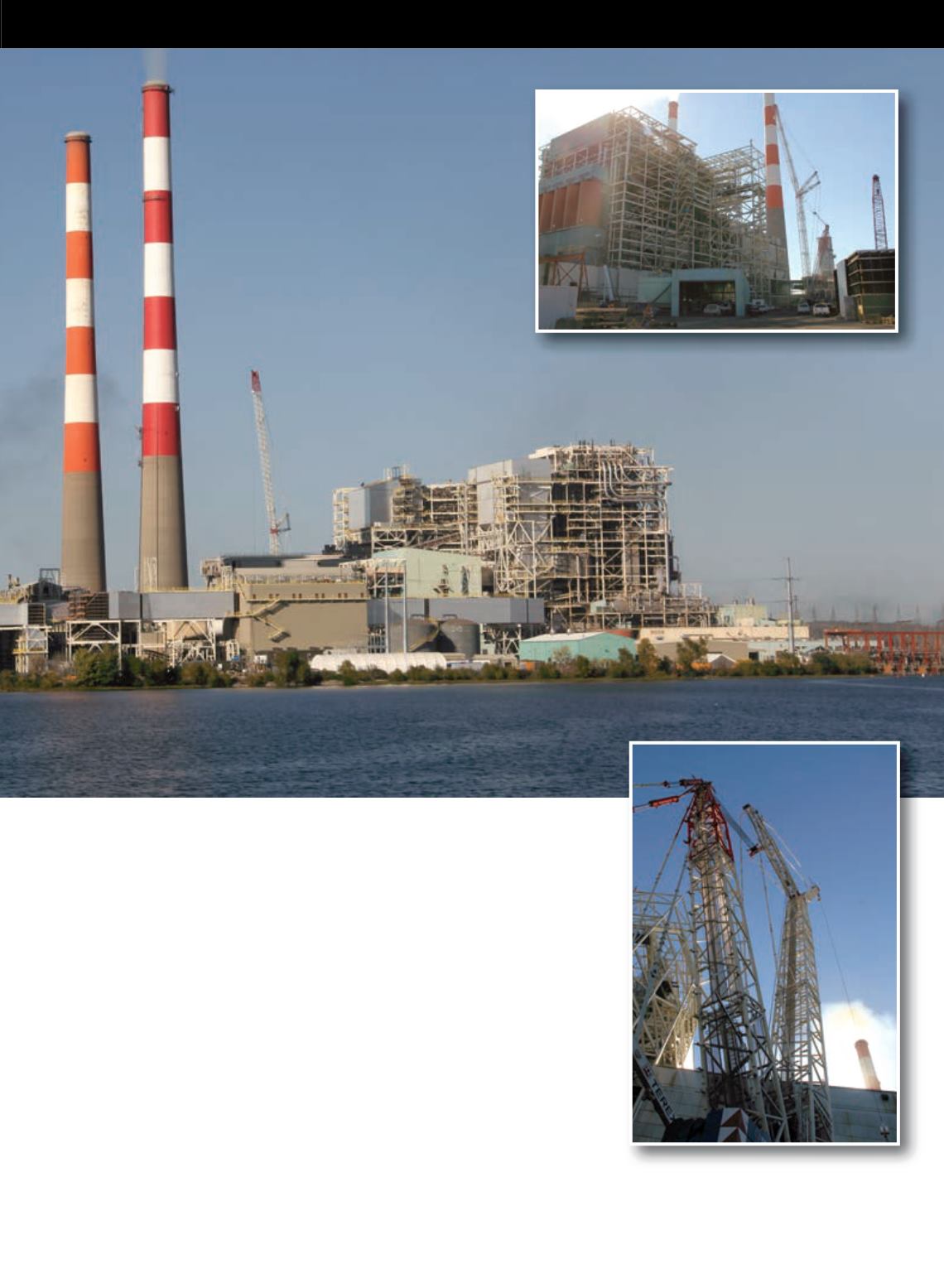

The Terex Superlift3800was taskedwith replacing rusted

ductwork at the La Cygne Generating Station in Kanas.

The Superlift3800 used amain boom

length of 177.2 feet, a luffing boom

length of 215.6 feet, a backmast of 118

feet to complete the lifts.