30

SITE REPORT

NOVEMBER-DECEMBER 2013

d

&

ri

for Structures software (ELS) provided by

Applied Sciences International (ASI). This

enabled three-dimensionally modelling of the

structures and application of the demolition

methodology.

In doing this Liberty was able to refine its

methods and demonstrate to the client the

resulting successful outcome well in advance

of undertaking any physical work. The seismic

impact of the structures was also modelled

to ensure the resulting ground vibration was

within acceptable limits, as an operating power

station was situated some 20 m (66 ft) from

the gas plant and some 80 m (263 ft) from

the reactor tower. Strict safety procedures

ensured zero health & safety incidents over the

complete time-frame of this project.

The first structure to be demolished was

the Briquette building. Given the complexities

of the structure, the methodologies were

constantly analysed and refined to ensure

the structure collapsed as intended with the

application of the required pull force. The

weakening cuts were designed so it collapsed

relatively simply, but ensured that the structure

was sufficiently stable so as to not pose any

risk to the team while preparation works were

underway. The structure was demolished

in two halves. The top section was removed

first, and then the bottom – utilising a similar

process of cutting by skilled oxy-cutting

personnel, hence weakening the structure,

and then applying a pull force to induce the

collapse. After the structure came over, the

DRI consultant inspected it to see the quantity

of DRI that had decanted out of the holding

bins. The structure was monitored for 24 hours

after collapse, allowing oxidisation to occur

and so minimising the risk to workers. Once

deemed safe, excavators began downsizing and

processing the scrap materials. The structure

was monitored throughout the downsizing

process to ensure any areas of DRI were

identified, isolated and treated prior to any

hand oxy-cutting taking place.

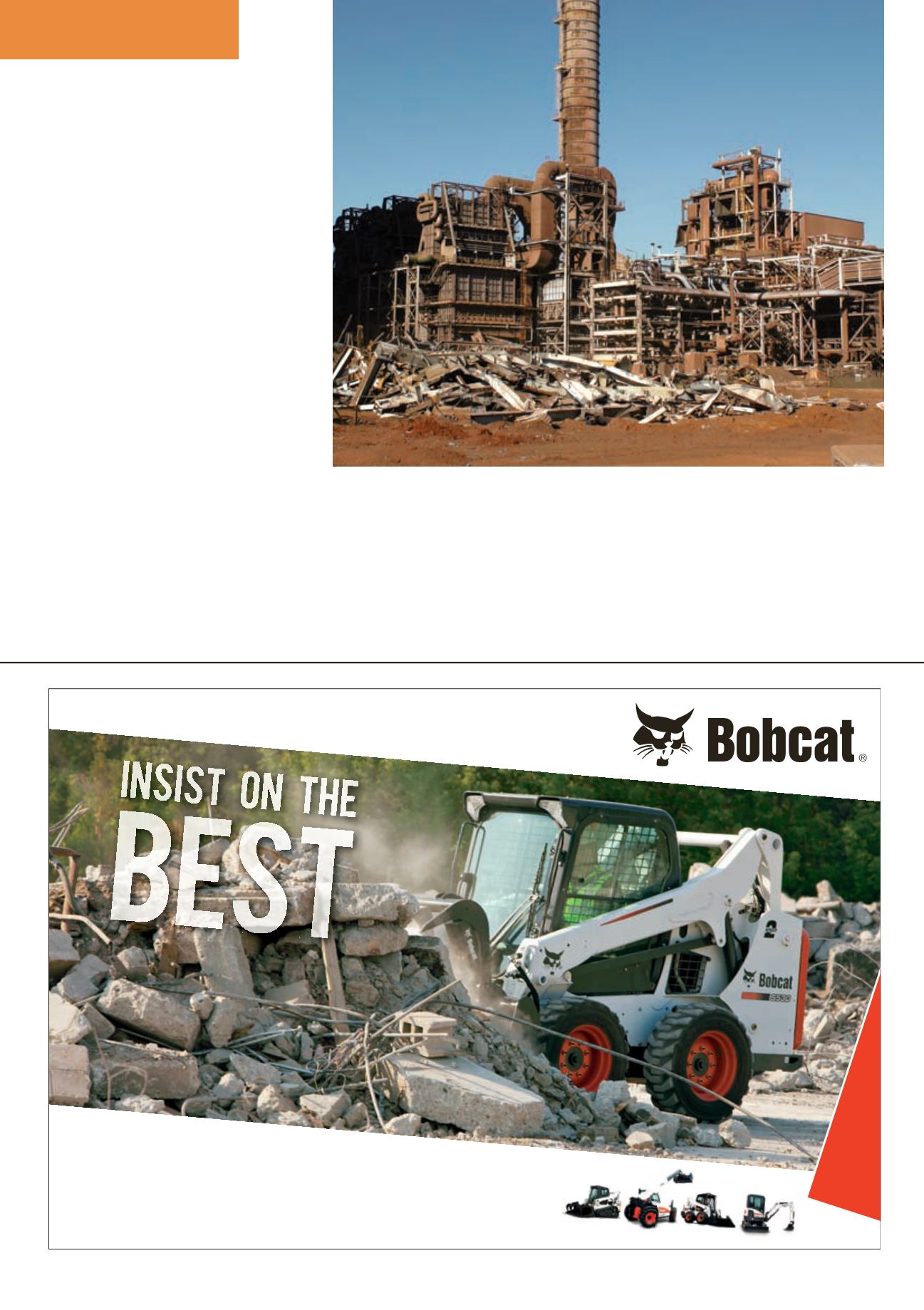

The gas plant was a series of pipe racks,

ovens, reformer structures and columns. It

contained substantial amounts of ducting,

heavy piping and plant equipment. Many of

the structures were collapsed using cut and

pull techniques - this then allowed the 230 and

The gas plant was demolished by excavators

equipped with shears and grapples

bobcat.eu/en/500

The best is now even better. The benefits begin with the larger, re-engineered cab that surrounds you with better

visibility and premium features. The improved lifting, digging, pushing and attachment power helps you accomplish

more and faster. Bobcat protects your machine and simplifies maintenance, helping you stay on the job.

Your Bobcat dealer will help you find the machine that’s right for you.