29

d

&

ri

NOVEMBER-DECEMBER 2013

Liberty Industrial faced a major challenge when it won the contract to demolish the

Boodarie HBI plant located in a remote region of Australia.

D&Ri

reports on the

project, which was shortlisted for the 2013 Industrial Demolition Award

T

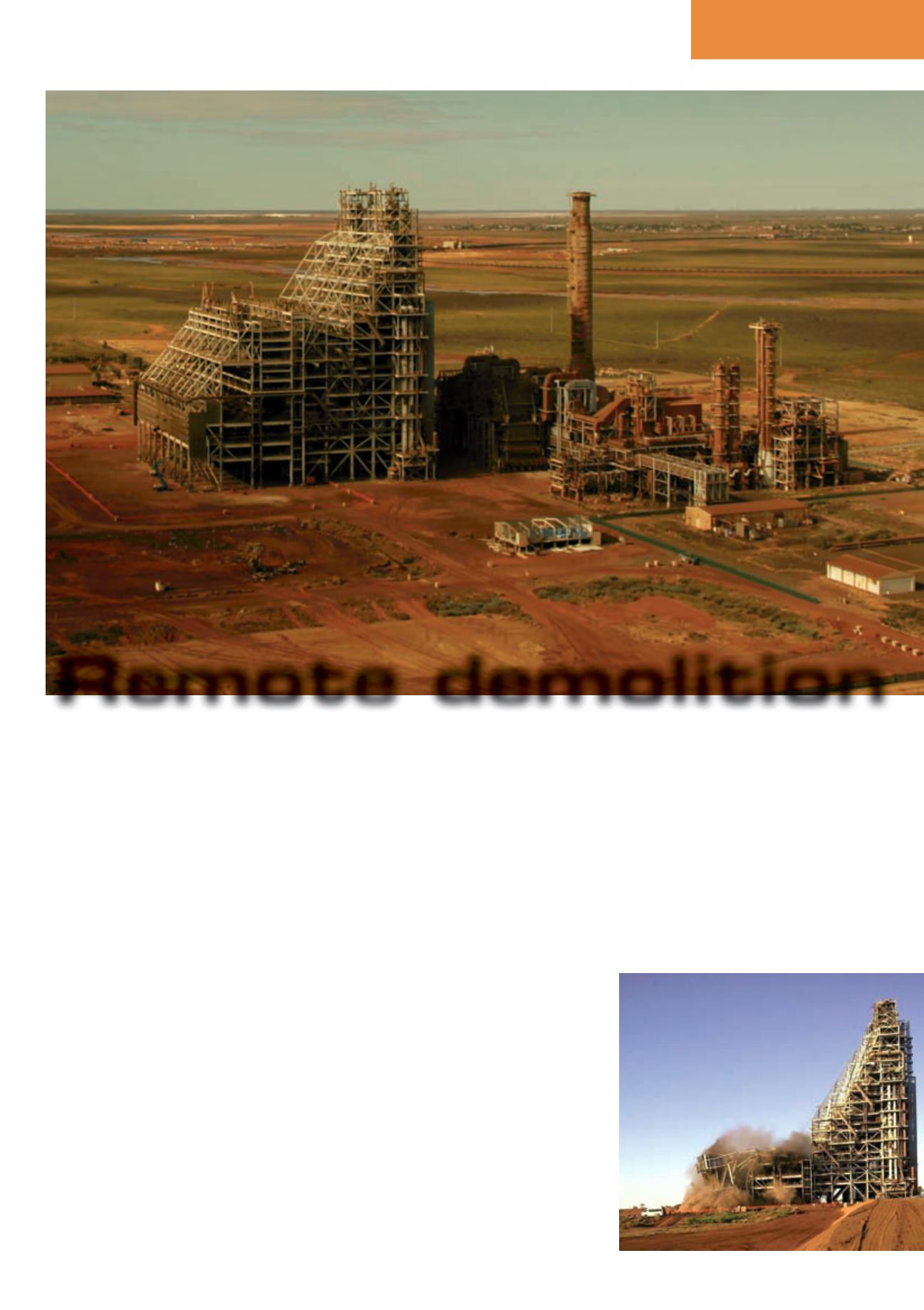

he Boodarie HBI plant was an iron ore

processing facility and one of the largest,

most complex demolition projects

undertaken by any demolition company in

the southern hemisphere over the past 15

years. HBI (Hot Briquetting Iron Ore) was

designed to make briquettes out of iron ore

fines. Located in Port Hedland – one of the

most remote regions of north western Australia

– the site was built to withstand cyclones and

earthquakes. The main HBI site (Stage 1) and

the Beneficiation plant (Stage 2) encompassed

the entire ‘Boodarie Closure Project’. With

structures that towered 100 m (328 ft) high,

and comprising over 25,000 tonnes of steel, the

Liberty Industrial demolition team demolished

the main HBI site with precision within the

first 12 months, and the Beneficiation Plant

within the next seven.

The main HBI site consisted of three main

structures: a 65m (198 ft) high briquette

structure, the 100 m high reactor structure, and

a 40 m (132 ft) high gas plant. Liberty utilised

its fleet of excavators including the largest

demolition excavator in Australia – a 230 tonne

Liebherr 994 complete with the largest set of

extreme weather on the planet, including

winds that can top 250 km/hr (155 mph). The

structure was built to withstand a Category

Five cyclone, so it was built to withstand

extreme conditions.

To minimise the inherent risks associated

with the demolition of the HBI structures,

Liberty made use of the Extreme Loading

Remote demolition

SITE REPORT

The HBI plant at Boodarie was located in one of

the most remote regions of north-west Australia

grapple attachments ever made by Embrey’s

Australia at 14 tonnes, an EX1200 Hitachi and

a series of 70 tonne, 46 tonne and 36 tonne

Volvo processing excavators all equipped

with the latest Genesis shears and grapple

attachments from Embrey’s

This high profile project was a landmark

facility for the Pilbara region of Western

Australia, and one that was within client BHP

Billiton Iron Ore’s top 10 world-wide risks due

to the presence of significant quantities of the

highly reactive material, direct-reduced iron

(DRI). DRI has the ability to generate hydrogen

gas when exposed to water or heat. This posed

a significant risk to the demolition team, as

quantities of DRI remained in confined spaces

such as pipe work or vessels.

APPROACH TO DEMOLITION

Commencing in May 2011, the main Stage 1

structures had to be on the ground by early

November, as November to April is cyclone

season in the Pilbara – potentially dangerous

conditions for demolition activities. The plant

was situated in the middle of the cyclone belt,

in an area that experiences some of the most

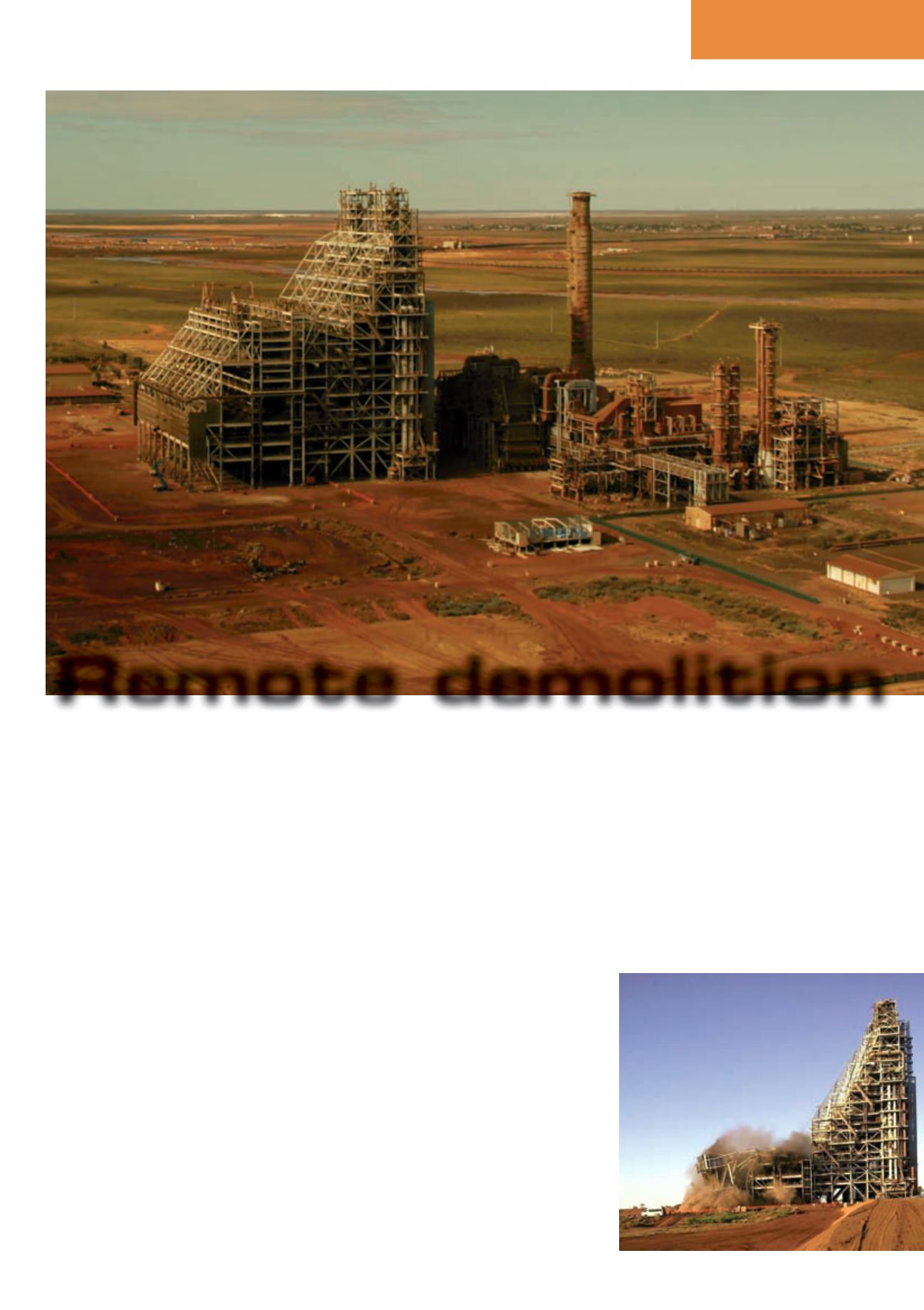

The briquette building

falls after cutting

weakened the structure

and excavators pulled it

down