10

MARCH-APRIL 2014

d

&

ri

CRUSHING

& SCREENING

Ever greater screening

efficiency

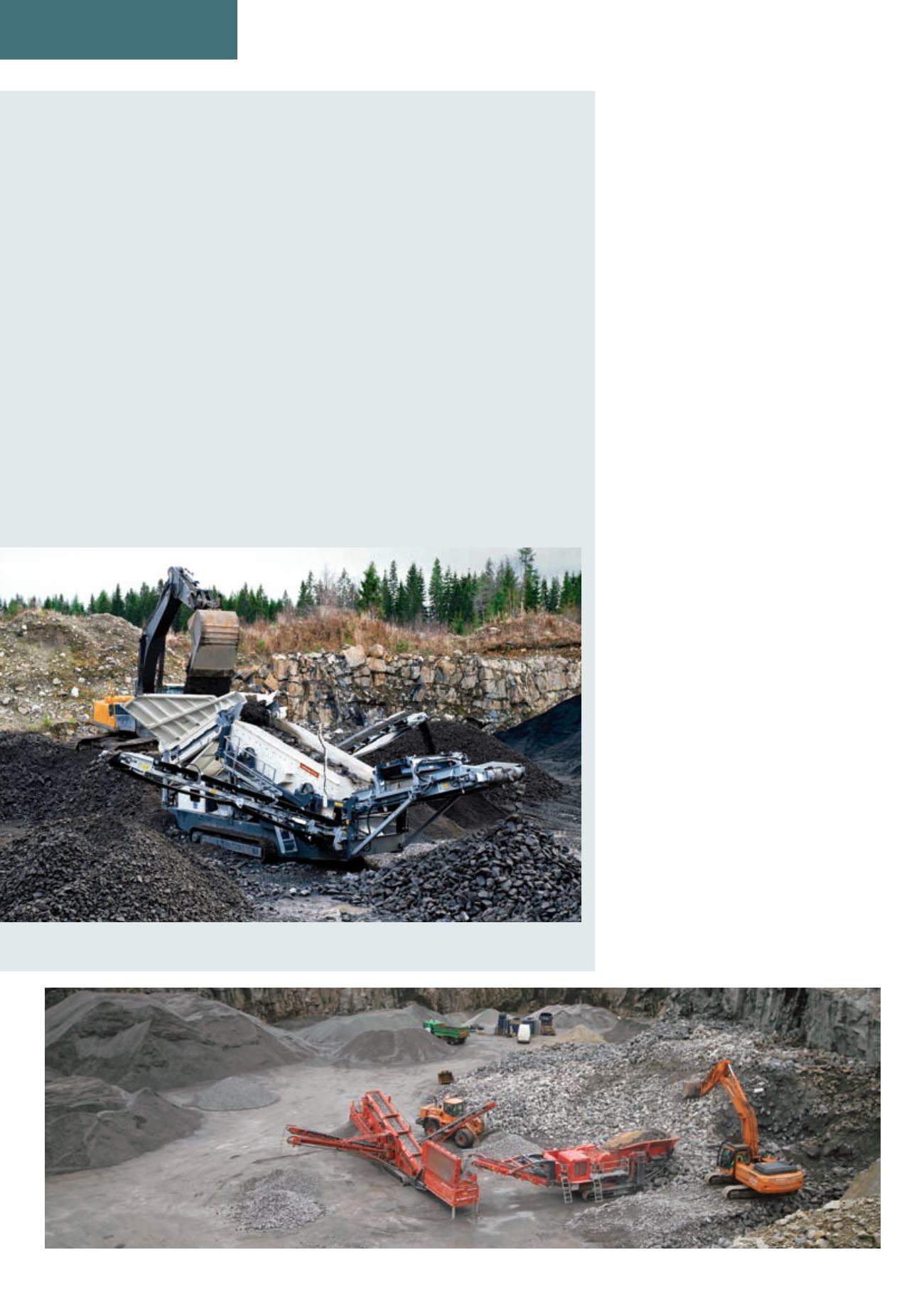

Metso also used ConExpo to introduce the new Lokotrack ST2.8 tracked two deck screener

that makes use of the company’s new Super Stroke Screen, which it says gives 20% higher

stroke and 20% more screening area on the second deck. High stroke translates into

power in material separation and a large screening area of 7.4 m

2

(80 ft

2

) and dimensions

of 4.8 x 1.5 m (16 x 5 ft) ensures that precision is achieved during fines separation. The

screen itself can be angled from 10 to 17 degrees.

In operating configuration, it is 14.4 m (47.3 ft) long, 11.2 m (49.7 ft) wide and 3.5 m

(11.6 ft) tall, The machine’s conveyors and chutes can handle up to 400 tonnes per hour

and equipped with an apron feeder, the ST2.8 weighs in at 33 tonnes.

According to Metso, typical applications include topsoil separation, demolition, quarries

and sand hills. The new screen performs at its best when the feed material is sticky, wet

and difficult, and high capacity is required, Metso went on to say. The ST2.8 can also cope

with metallic material with the addition of a magnetic separator and drums.

Power comes from a Caterpillar C4.4 diesel delivering 75 kW (100.6 hp) and the use

of a new hydraulic system has resulted in a reduction in fuel consumption of 25%. The new

Lokotrack can also be powered using an external electricity supply and using an intelligent

control system.

On-site setup is easy with no requirement for the use of a crane or special tools. Push

button control and Service DVD makes Lokotrack machines safe and easy to operate, an

essential feature when the machines are used in the rental sector where high production

and up-time are a requirement.

a new look from Powerscreen. The traditional

Powerscreen green colour is maintained, while

a dark grey colour is adopted on the chassis

and conveyors.

The Premiertrak 300 jaw crusher

features the new hydrostatic drive system

option allowing it to reverse and unblock

or run continuously in reverse for asphalt

applications. Powerscreen said it was designed

to run at low engine rpm, resulting in fuel

efficiency and low noise emissions, and

therefore it is ideal for urban sites. It features a

vibrating grizzly feeder (VGF) set with 50 mm

(2 inch) bofor bar on the top deck and 30 mm

(1.2 inch) mesh on the bottom. The closed side

setting (CSS) can be set to 40 mm (1.6 inch)

while running in both asphalt and recycled

concrete applications.

Other benefits of the machine are said to

include large clearances in the bypass chute

to improve material flow and reduce the

chance of blockages in sticky material. Also,

Powerscreen claims a large under crusher

clearance and full tunnelling to reduce the

chance of blockage as a result of re-bar build

up. A hydraulically lowering conveyor is said

to offer excellent access to reduce downtime

should a blockage occur.

The Trakpactor 320SR is a mid-sized

horizontal impact crusher redesigned with

some key enhancements that Powerscreen

said would offer operators and contractors

excellent reduction and high consistency of

product shape for performance in quarry and

recycling applications. The plant is described

as capable of working in the most demanding

environments. The company said that features

included rapid set-up time, a fuel-efficient

direct drive system and output potential of up

to 320 tonnes/hour.

The plant features a recirculating conveyor

that raises for transport. The Trakpactor

320SR crusher has a quick-detach post-

screen section that converts it to a standard

Trakpactor 320 unit, which Powerscreen said

provided operators with versatility to use the

machine in a variety of different applications.

The Warrior 2100 screen is the first

screen to be designed by the company

with recycling firmly in mind and includes

Powerscreen’s Triple Shaft technology that

was first developed for the Warrior 2400.

This technology is designed so the screen box

is effective and efficient while maintaining

>

12

Metso’s new Lokotrack ST2.8 screen has been designed to be suitable for recycling applications as well as

multi-stage crushing processes

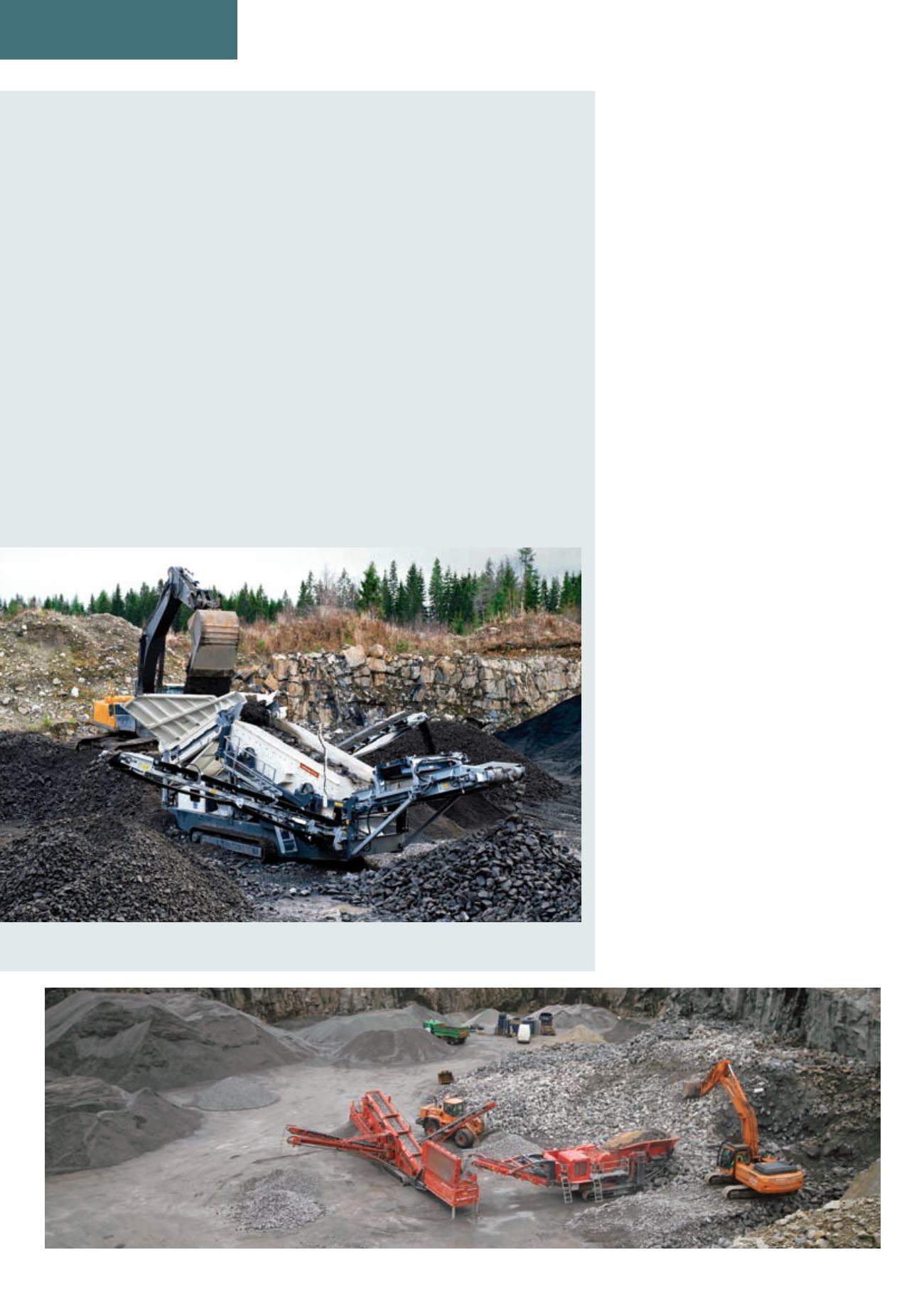

The J-1170 primary mobile jaw crusher and the 684

tracked mobile inclined screen from Terex Finlay