9

d

&

ri

MARCH-APRIL 2014

>

12

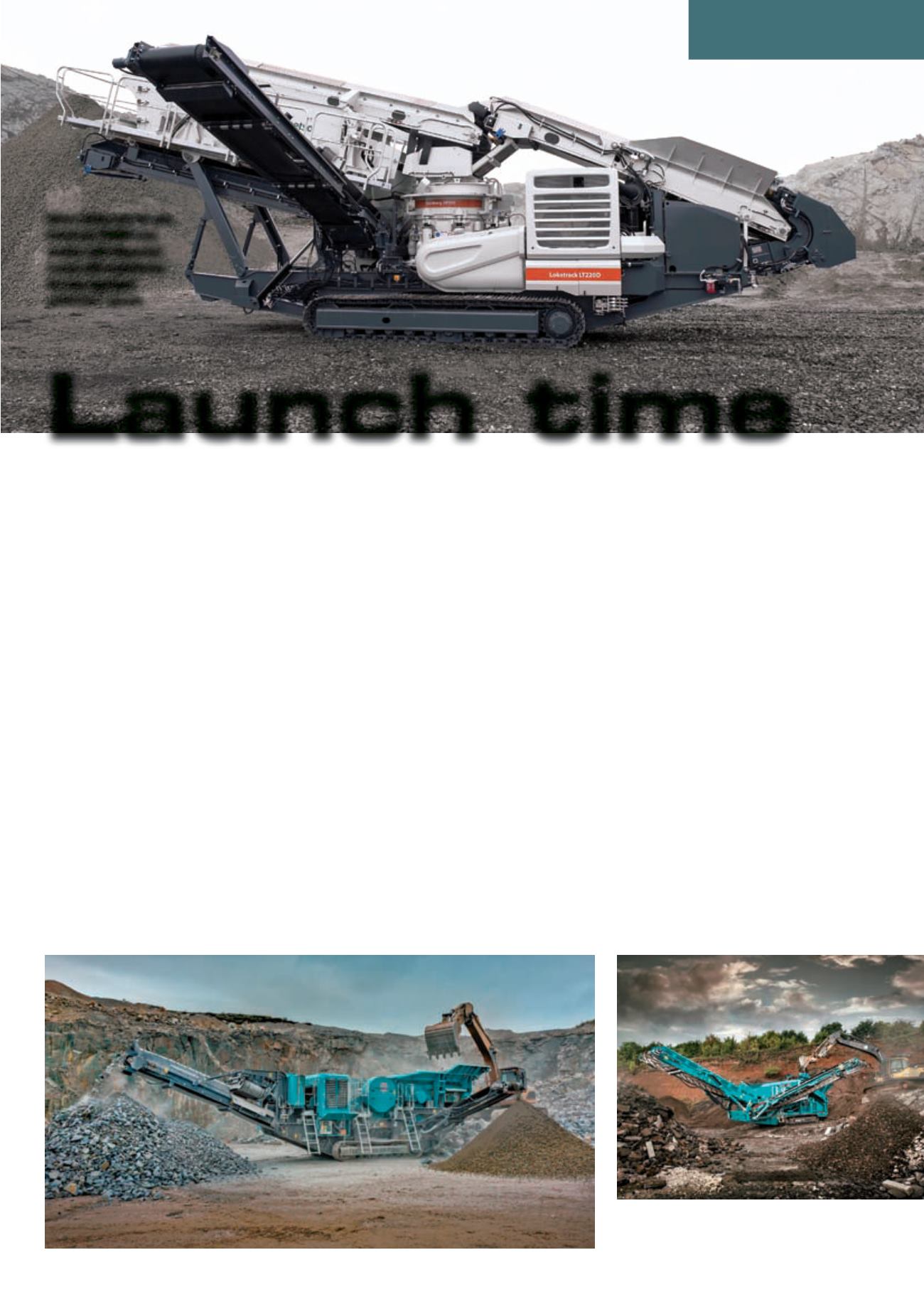

Meanwhile, a reduced number of

transported units and a quick set-up translate

into a significant increase in effective

production time. Hydraulically operated

screen lifting and folding side conveyors

enable the Lokotrack LT220D to be ready for

action in just minutes. The total weight of 47.7

tonnes and its compact transport dimensions

make the LT220D easily transportable around

the world, giving contractors plenty of

flexibility with the unit.

The Lokotrack LT220D is equipped with a

proven, high-performing Metso cone crusher,

either the HP200 or the GP220, with an

intelligent control system ensuring safe and

reliable processes in all applications. Paired

with Metso’s Lokotrack LT106 mobile jaw

plant, the new secondary unit is capable of

producing up to three calibrated end products.

The new crusher was joined at ConExpo by a

new mobile screen in the shape of the ST2.8

(see box story).

GOING FOR RECYCLING

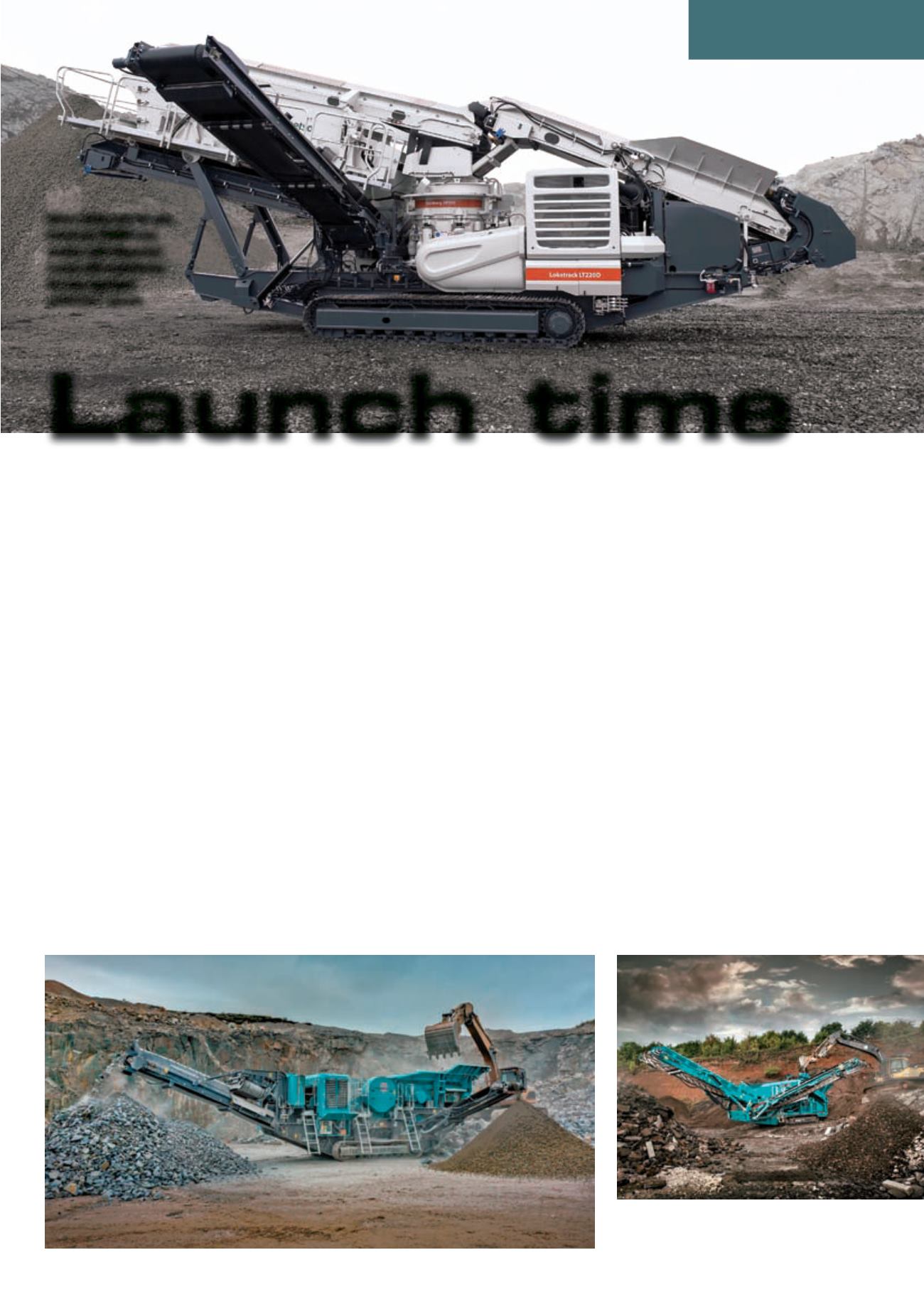

Powerscreen also had three new machines on

show at the exhibition – the Premiertrak 300

jaw crusher, Trakpactor 320SR impact crusher

and Warrior 2100 screen.

All of the machines on display showcased

Metso claims that its new

Lokotrack LT220D cone

crusher with integrated

screen will revolutionise

the way aggregate

contractors operate

Recent months have seen a spate of new mobile crushers

come onto the market, in part due to changes in engine

emission regulations.

D&Ri

takes a look at the sector

Launch time

CRUSHING

& SCREENING

not make it to the show.

For example, Metso introduced a new

Lokotrack at the show in the shape of

the LT220D mobile cone crusher with an

integrated screen on the same chassis, a

combination that the company claims will

‘revolutionise the way aggregate contractors

operate around the world’.

According to Metso, the new machine will

reduce costs for contractors in several ways,

most notably from its substantially lowered

fuel consumption and a reduction in the

need for maintenance. In addition, the unit is

compact and highly transportable.

The fuel economy of the LT220D is the sum

of several features. Running both the crusher

and screen with a single Cat C13 309 kW (415

hp) diesel clearly makes a big difference. An

efficient power transmission system enables

maximum power for operating. The result is

substantially decreased fuel consumption with

no compromises on capacity.

Powerscreen’s Premiertrak 300 jaw crusher features

the new hydrostatic drive system option

The Warrior 2100 screen has been designed with

recycling applications firmly in mind and includes

Powerscreen’s Triple Shaft technology

R

ecent news concerning the closure of

Sandvik’s manufacturing facility in

the UK (see news this issue) suggests

that for the crushing and screening sector

a recovery in market conditions from the

downturn that occurred in 2008-2009 is still

some time away. Nevertheless, manufacturers

at the larger equipment end have not slowed

or halted their R&D activities, although

to be fair one driver is the ever tightening

engine emission regulations around the world

that have filled the pages of this and other

magazines with news on new equipment.

In the last issue, we reported very briefly on

the latest large mobile crushing and screening

equipment that was to grace the showground

at the recent ConExpo exhibition in Las Vegas.

In this report, we take a more detailed look at

these machines, as well as some others that did

>

10