international

construction

september 2014

HIGHRISE

34

Topping out

As theworld’s 100th super-tall building tops out,

suppliers to the high-rise construction sector are raising

their game to ensure their technology keeps upwith

ambition.

SarahMcCay

reports

T

his year saw the 100th ‘super tall’ building of more than

300 m built when the Jiangxi Nanchang Greenland

Central Plaza, towers 1 and 2, topped out in June, in

China. The 303 m Jiangxi project is now the tallest building

complex inNanchang, stepping above the International Finance

Centre (239 m) and the still-under-construction Jiangxi

NanchangGreenlandZifengTower (268m).

More than half of the world’s tallest buildings have been built

in the last four years, with the total super tall category almost

tripling in the last seven years.

The world’s current tallest building – the Burj Khalifa in

Dubai, UAE – towers 828m above the desert. However, it will

lose its crown when the 1 km high KingdomTower in Jeddah,

Saudi Arabia is completed.Meanwhile, there are plans inChina

for the 1 km Phoenix Towers, inWuhan. If this project goes

ahead, it will undoubtedly be designed to eclipse the Kingdom

Tower.

For thoseworking in the construction sector, being involved in

a high-rise project canoftenmark the pinnacle of a career. From

architects with a sky-high vision, to contractors and equipment

manufacturers offering cranes, access equipment, formwork or

concrete pumps, high-rise often comes with high prestige and

high payout, alongside high build costs and high risk.

As architects getmore ambitious,manufacturers need to create

equipment that is up for the job, nomatter how high.

US manufacturer Reed offers a specially developed high-

rise concrete pump. A 164 kW Cummins Diesel and 180cc

main hydraulic pump powers the new C90S concrete pump.

According to Reed, the pump offers a maximum output of

69m

3

per hour, which allows for high-output vertical pumping.

FreddyAlmeidaofAlmeidaConcretePumpingandEquipment

is a dealer, distributor and supplier of theC90S.

“At moment we have four including ours, which are working

on buildings from 20 to 40 floors. Each one of these pumps is

used 2-3 times per week and is performing very well. One of

our customers just finished a 40+ storey building in Brooklyn,

while two inManhattan of 30+ floors and are currently being

worked on,”Mr. Almeida explained.

“This is one of the more affordable and faster ways to get a

job done with the least amount of manpower. We are seeing

more buildings raised up with companies using this type of

equipment, including the tallest buildings being built in New

York,” he added.

Frompumps to formwork, bothhavebeen the long-considered

constructionmethod of choice for high-rise developments.

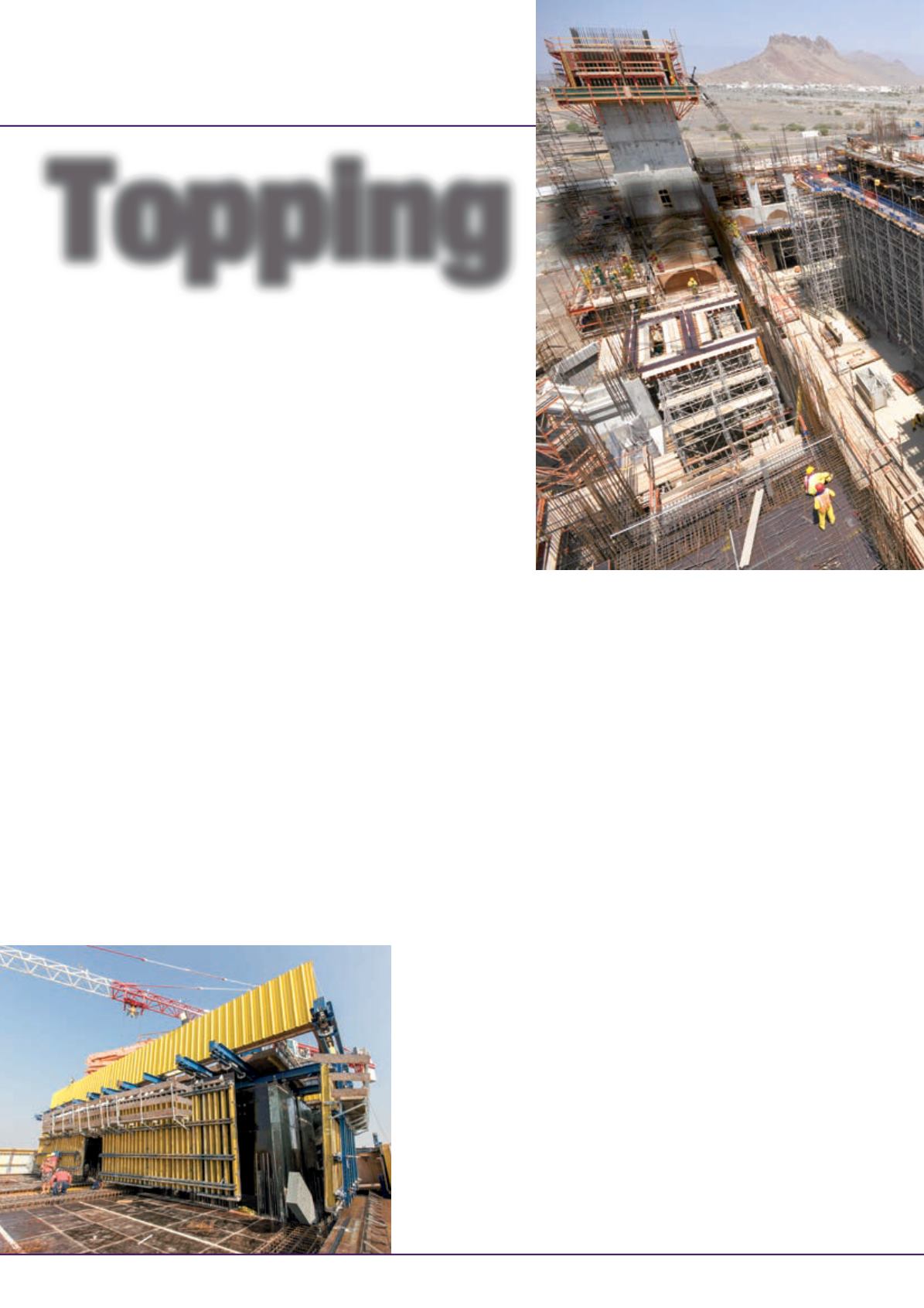

Carillion Alawi is working with RMD Kwikform on the

construction of the US$ 64 million landmark Sultan Qaboos

Mosque inNizwa, Oman.The site has required shoring towers

of up to 43 m high, to support the casting of the mosque’s

dome, as well as concrete slabs and beams.

Innovative solution

Facedwith a change in programme sequencing, which required

both beams and slabs to be cast at the same time, engineers

from RMD Kwikform designed an innovative solution to

erect a run of Rapidshor shoring support inside the previously

erected Alshor Plus birdcage, specified for the initial works.

By combining both Carillion Alawi was able to speed up the

construction cycle for the project.

“The dome was the ultimate challenge,” admitted RMD

Kwikform regional sales manager, Bellphine Campbell.

Topping out

RMDKwikform placed a 900mmwide run of Rapidshor

shoringwithin the Alshor Plus birdcage support to speed up

construction at the Sultan QaboosMosque in Oman.

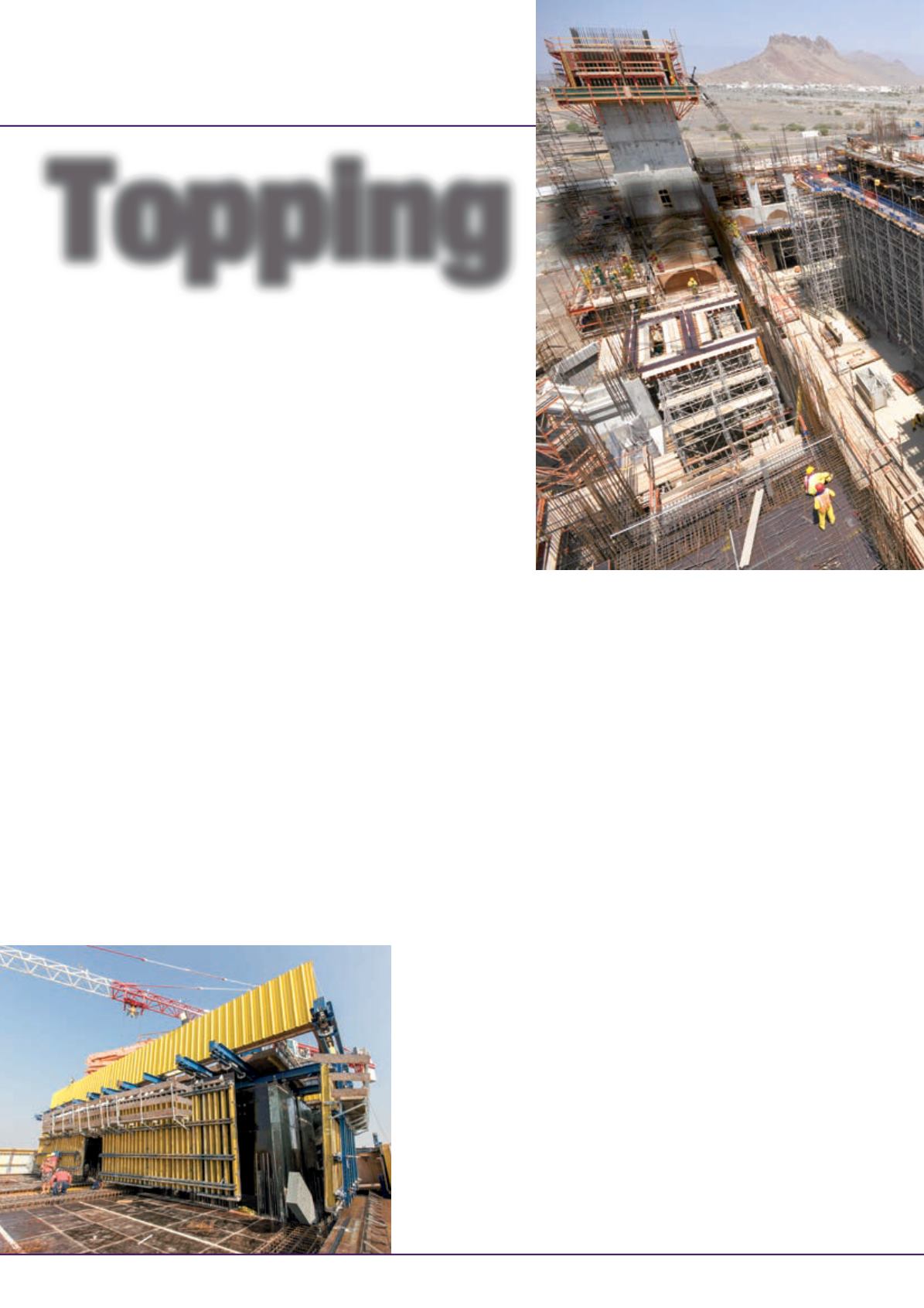

Doka’s SKE100

automatic

climbing

formwork

plus is used to

hydraulically

raise the

formwork

modules in a

manner that is

fully automated

at the Torre

Isozaki building

in Italy.