international

construction

september 2014

WHEELED LOADERS

26

Economy drive

>

perhaps unreliable as well due to fuel quality issues and the tight

tolerances inherrent inTier 3 engines.

What is interesting is that manufacturers are taking the

opportunity to design loaders with features specifically designed

for emerging markets, rather than just taking a previous year’s

European orUSmodel with a lowerTier engine.

One example of this comes from the fact that many emerging

markets are in tropical or equatorial regions, so there is often

a need for more serious engine cooling, air filtering and air

conditioning.

Meanwhile in developed markets, all the technology that has

been added to engines to reduce emissions has of course pushed

up purchase prices. In order to helpmake thismore palatable to

their customers, loadermanufacturers have been looking atways

of improving fuel efficiency and cut other running costs on new

models.

For example, Volvo’s new L250H wheeled loader, a Tier 4

Final machine, is claimed to offer 18% better fuel economy

than predecessor models thanks to the company’s Optishift

transmission system.

This covers several technologies, one of which is calledReverse

By Braking (RBB). In short cycles, operators tend to switch

rapidly between forward and reversemovements, and thismeans

the loader tends to be slowed down by the torque converter,

rather than the brakes. This is less efficient than using the

brakes and also strains the transmission. RBB gets round this

by automatically applying the service brake, even though the

operator might be using the machine in the same way with the

forward/reverse lever.

In a similar class to the 35 tonne operating weight L250H

are Caterpillars new 980M and 982M wheeled loaders, which

weigh in at 34 and 36 tonnes respectively. Again, fuel efficiency

improvements on theseTier 4 Final machines are a key feature,

F

lix, Spain-based Trans-Crispi has bought a newDoosanDL350-3wheeled loader for

arduous day-to-daywork. The family business is active in concrete supply, excavation,

container rental, wastemanagement & transportation and publicworks. However, one

of itsmain activities at themoment is the extraction, transportation and disposal of waste

sludge from a chemical plant near its headquarters.

Company director AntonioOrtega said, “We previously had another brand of wheeled

loader, but we needed onewith a higher bucket capacity for the sludge removal task, to fully

optimise our work.We also needed a toughermachine because thiswork is quite harsh, with

12 hour days on average. The newDoosanDL350-3 is an excellentmodel in terms of bucket

capacity, static tipping load capacity and standard equipment, which is very complete and

technologically advanced.

“It will beworking at the landfill and the concrete plant, loadingmaterials into containers

and trucks or transporting them at our facilities. It will also be used to perform tasks for our

clients, such as the sludge removal job.

“We are very pleasedwith themachine’s performance so far. Its power, load capacity and

speed arewell balanced. We are also happywith its safety levels, as thismodel includes all

the necessary equipment required under European regulations.”

Themachine is equippedwith a Stage IIIB-compliant Scania engine delivering 202 kW. The

transmission and axle are from ZF.

Newworkhorse

Doosan loader chosen for arduouswork

Following a successful trial Southwick, UK-based aggregates

and cement company Dudman Group has bough seven

Liugongwheeled loaders. The largest is the 888III, which

weighs in at 30 tonnes and features a 250 kW Cummins

QSM11 engine.

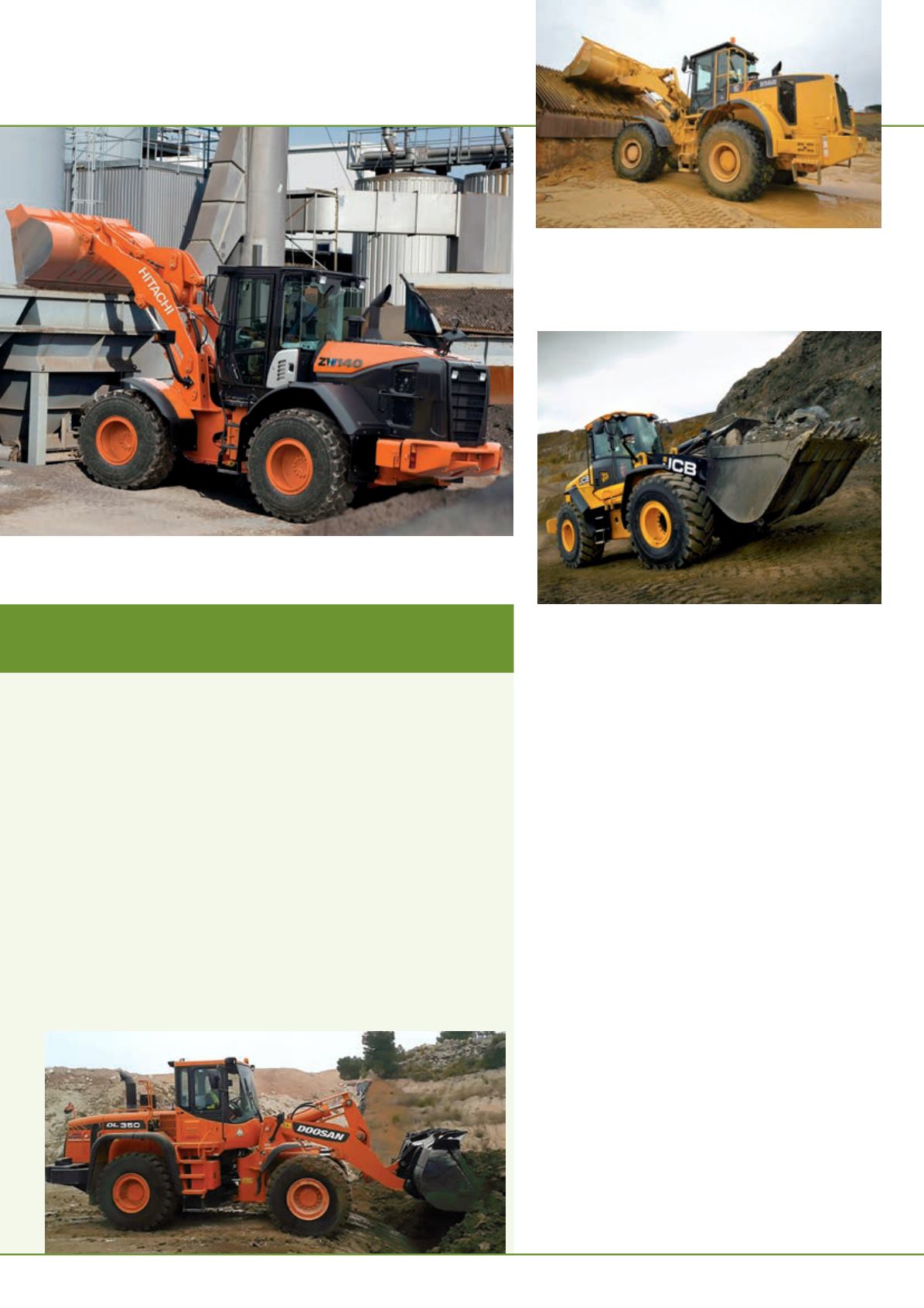

A hydrostatic transmission has helped reduce

fuel consumption on Hitachi’s ZW140-5 by -20%

compared to the predecessormodel.

JCB previewed its first Stage IV loaders at Hillhead. It says

the use of anMTU engine on the range-topping 457 has

contributed to a 16% overall fuel economy saving.