25

september 2014

international

construction

Economy

drive

Different engine regulations in developed

and emergingmarketsmeanwheeled

loaders now vary a lot from country to

country. However, the drive to increase

fuel efficiency is common around the

world.

Chris Sleight

reports.

M

ore and more of the wheeled loaders being sold in

Europe, Japan and North America are now fitted

with a new generation of low emission engines. Stage

IV (Europe) and Tier 4 (US, Canada and Japan) requirements

started to come into force last year.

It takes timeafter the implementationdate for thesenewengine

machines to reach themarket.Manufacturers are allowedvarious

flexibility provisions to use up stocks of older engines as well as

sell other ‘oldTier’ machines once the new laws have come in.

But as time goes on thesemachines work their way through the

system, and more and more Tier 4/Stage IV loaders find their

way to construction sites.

Many other parts of the world also have emissions regulations

that apply towheeled loaders and other off-highway equipment

for construction, mining and agriculture. At present the most

stringent of these is the equivalent to the older Stage IIIA/Tier 3

laws.Andof course there aremanyparts of theworldwhere there

are no emissions regulations at all.

Themain reason lesser regulated countries have stopped atTier

3 levels is that above this fuel qualitybecomes a critical issue.The

various aftertreatment systems used to achieve Stage IIIB/Tier

4 Interim and Stage IV/Tier 4 Final require ultra low sulphur

diesel – about 10 or 15 parts per million(ppm) of sulphur. Any

higher than this and exhaust after treatment systems like diesel

particulatefilters (DPFs) and selectivecatalytic reduction systems

(SCR) get cloggedwith soot, and the enginewill overheat.

Sountil ultra low sulphur diesel iswidely available in emerging

markets, these countries will likely stay atTier 3 emissions levels

at best, even though many governments have a desire to make

regulationsmore stringent.

Parallel development

This divergence of developed and emergingmarkets has had an

impact on the models manufacturers produce. Wheeled loader

makers that want to be global now have to produce at least

two ranges – a Tier 4 model for developed markets and a Tier

3 model for lesser regulated countries. Some would also argue

the need for a ‘Tier 0’ machine, as in many countries a Tier 3

modelwouldbe over-sophisticated (uncompetitivelypriced) and

WHEELED LOADERS

Economy drive

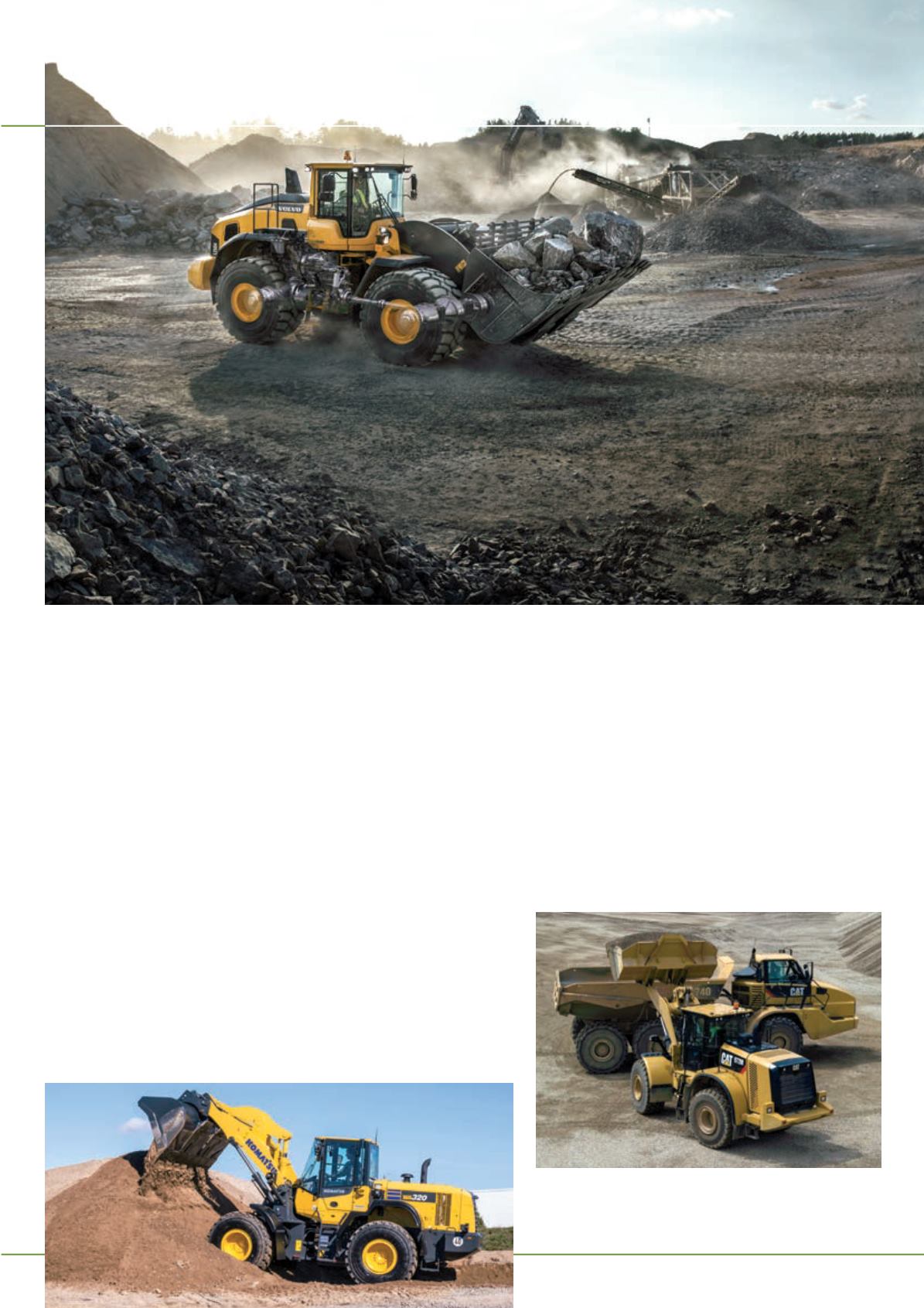

Volvo’s Stage IV-compliant L250H is said to offer 18% better

fuel economy than its predecessor thanks to the company’s

Optishift drivetrain technology.

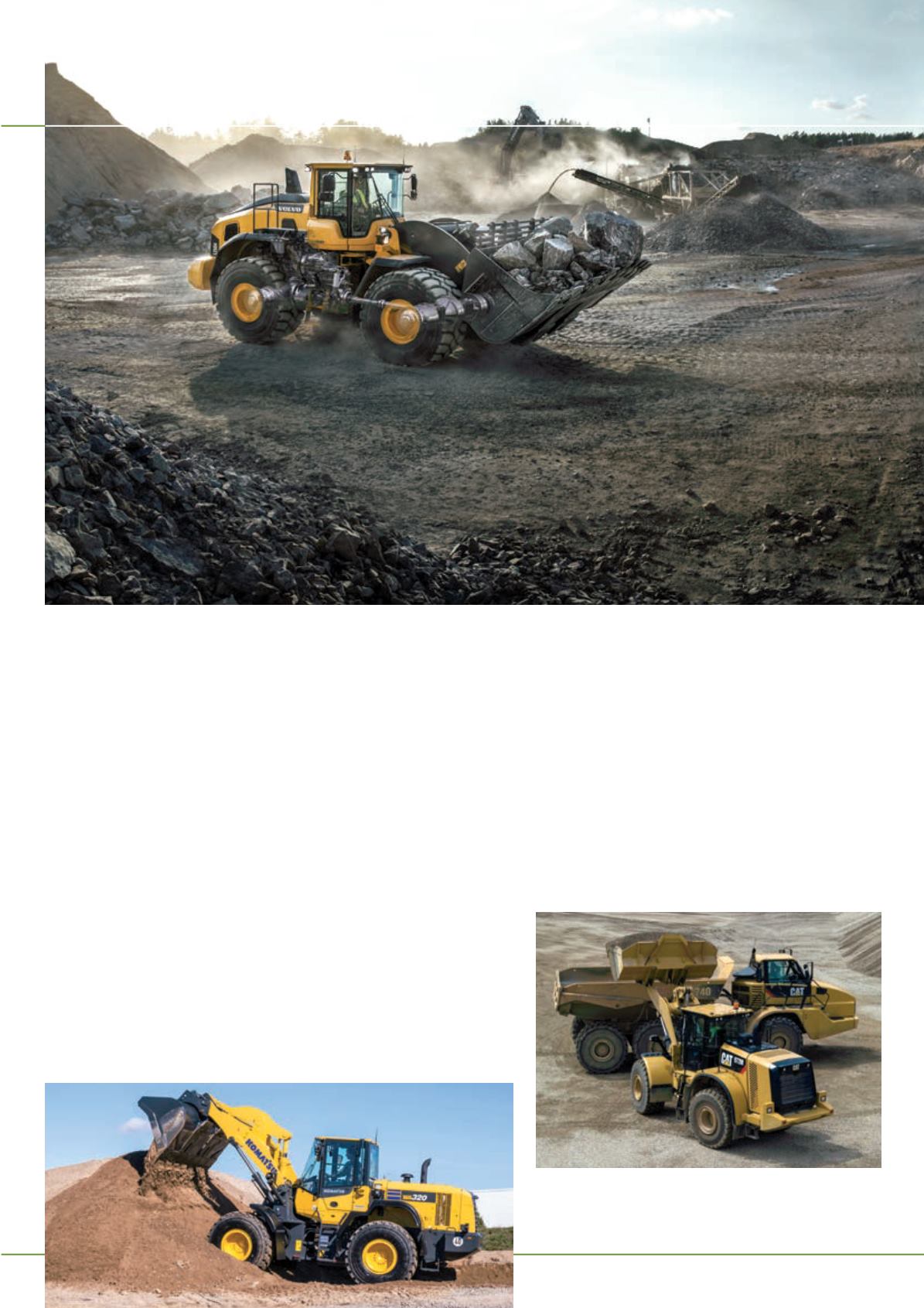

Caterpillar’sM-seriesmedium sizedwheeled loaders are

availablewith its XE technology, a continuously variable

transmission delivering -25% lower fuel consumption than

machineswith traditional drivelines.

Komatsu’s

WA320-7 features

the company’s

parallel Z-bar

front end, which

gives it good

breakout forces as

well as the ability

to parallel lift.

>