13

d

&

ri

SEPTEMBER-OCTOBER2014

BREAKERS

Regulating

the

European

market

Hydraulic attachment tools are being

represented in a new group within the

Committee for European Construction

Equipment (CECE) trade association.

This will act as a communication and

information platform for companies

operating in the field, including Arden

Equipment, Atlas Copco, Caterpillar,

FRD, Indeco, Montabert, NPK, Okada,

Sandvik, Simex, Socomec, Soosan, Tabe,

Toku and VTN.

The product group is chaired by

Torsten Ahr, vice president of marketing

at Atlas Copco Construction Tools. He

said: “Especially the sub-segment of what

we refer to as silent demolition tools

will see a steady upturn over the next

few years as the industry turns towards

more efficient solutions in demolition and

recycling.”

CECE said the era of the

sledgehammer and the wrecking ball

was over inmany parts of the world, and

that sophisticated tools like crushers,

pulverisers, grapples and scrap shears

were now being sought after.

The product group will be a

platform for discussions concerning

EU-legislationmatters that are

particularly relevant to the section –

such as the outdoor noise directive

– and to share information about

market developments.

Statistics on hydraulic breakers

and demolition tools will be another

core service, said CECE, who

claimed it was the only supplier of

worldwide data of this kind. Torsten

said of this: “We are happy to supply

such a unique tool to our manufacturers,

helping them to understand better their

market situation and their competitive

environment.”

One of the crucial future topics of

the group, according to CECE, will be

to address the problem of hydraulic

breakers that are coming to the

Europeanmarket but that do not

comply with the European safety and

environmental legislation.

The scope of products in this section

of CECE also includes niche products

and highly specialised solutions such

as screening buckets, mounted plate

compactors and rotary drum cutters.

system that has beendesigned to extend

the carrier’swork life by absorbing

harmful vibrations and stress

waves.

Optional features include an air

pressurisationkit for underwater

applications, aswell as an automatic,

cradle-mountedgrease station

that delivers continuous oil flow,

reducingbushing and toolwear.

Montabert claimed that,

in comparisonwith similar-

sizedhydraulic breakers, the

501NG requiredminimal

maintenance, increasing

operator productivity. It

said the breaker’s simple

design– characterisedby

fewerwear parts andno tie

rods – enabledoperators

to complete routine

maintenanceon-site

more efficiently andwith

standard tools.

At the larger endof

the breaker scale, the

latest breakers from

Dehaco come in the form

of the Ibex range, developed

for excavatorsweighingup to

46 tonnes. Akey feature is the

advancedhydraulic circuit

on the range that provides

increased flow to the valve

andpiston, resulting in

faster cycle times, increased

rodpenetration andmore

productivity than the

manufacturer’s previous

models.

JCBoffers a 16-strong

line-upof JCBHammermaster hydraulic

breakers that it said suitedboth its own

and competitormachines from0.5 to55

tonnes. They aredesigned tobreak asmuch

material as possibleusingminimal power –

enablingquick and efficient completionof

jobs. There is a choiceof breaker tomatch

the job, whether for utilitywork, building

and construction, demolition and secondary

breaking, quarryingormining.

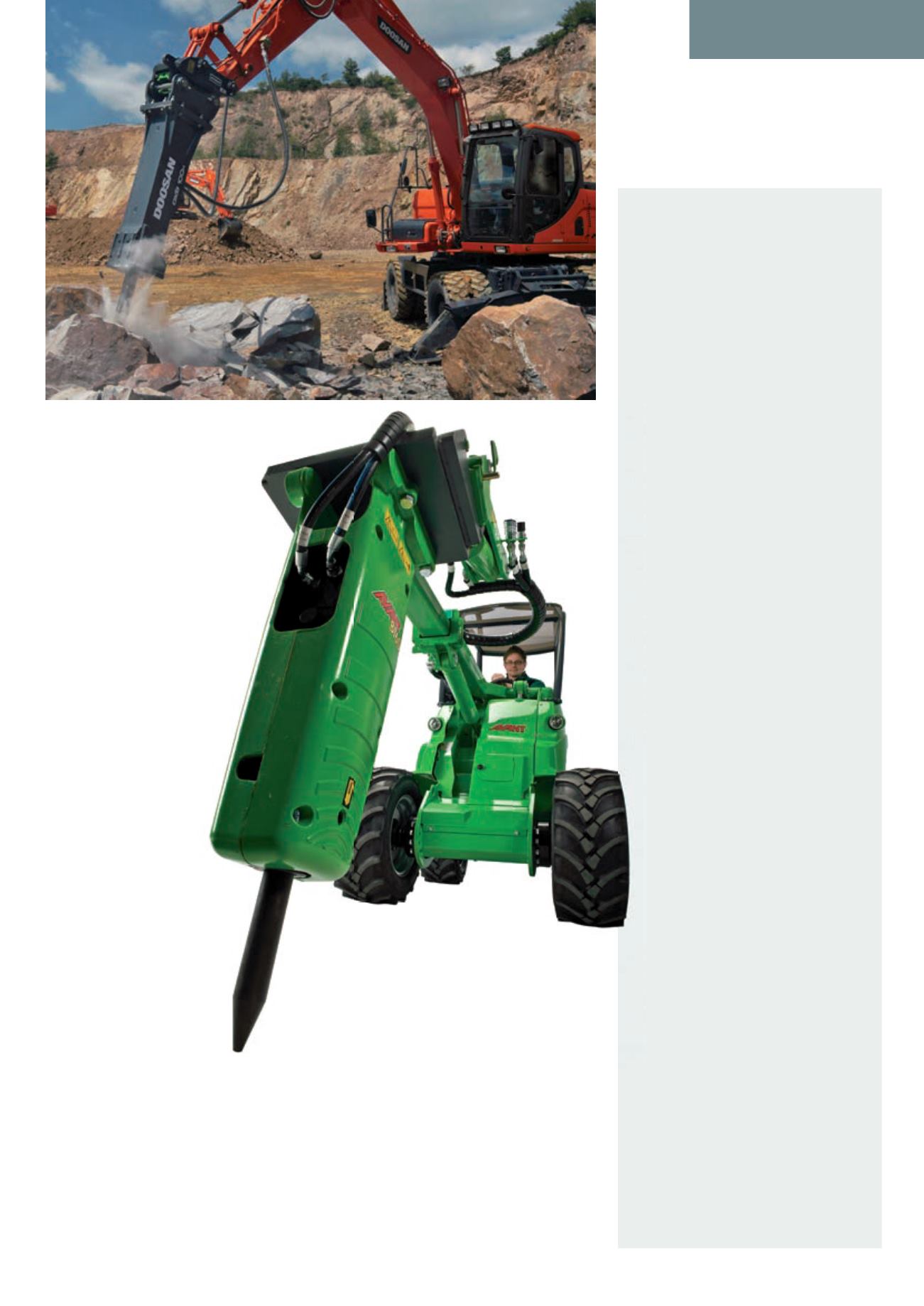

The Avant B160 is specially designed for Avant

loadermodels

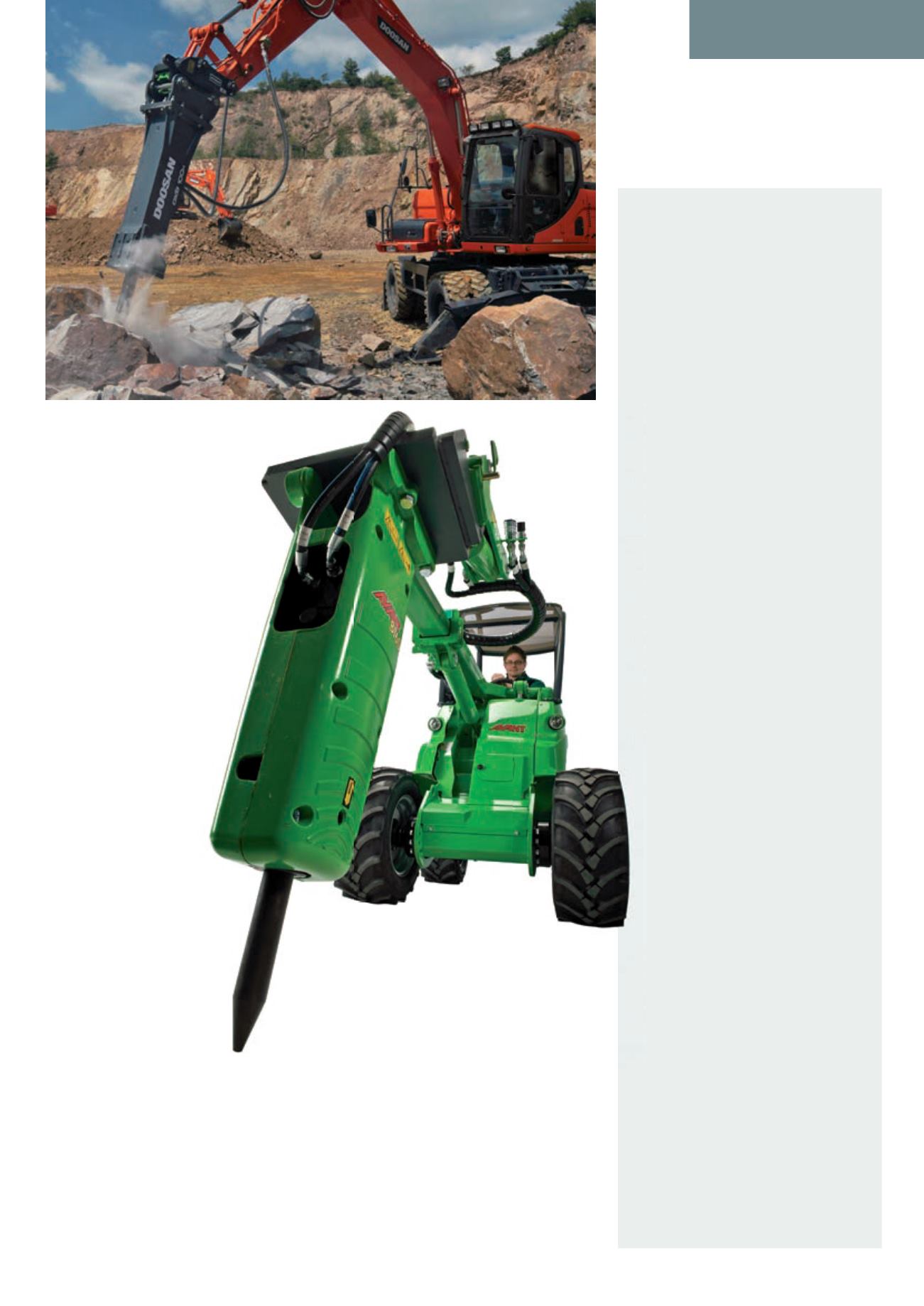

The Doosan DXB100H, one of five

hydraulic breakers for use on Doosan

wheeled and crawler excavators from

14 to 38 tonnes

JCB says its rangehas been specifically

designed tomatch its ownmachines’

requirements, including all excavators, skid

steer andbackhoe loaders.However, its larger

breakers can alsobe suppliedwith auniversal

fitmentwithout ahanger bracket, enabling

them tobe fittedon anymachines using

dedicatedquickhitch systems.

The compactHammermastermodels

incorporate a sealed-for-life accumulator and

only require rechargingduring a full rebuild

service, says JCB. This, togetherwith a grease

retention seal in the lower tool bush is said to

ensure longer life and smoothoperation. Each

is fittedwith full length sideplates giving full

protection against accidental damage.