38

DEMOLITION AWARDS SUPPLEMENT 2014

d

&

ri

RECYCLING& ENVIRONMENTALAWARD

INDUSTRIALDEMOLITIONAWARD

Brandenburg Industrial ServiceCo.

Merck Flint River Plant,

Albany,Georgia

Brandenburgwas contracted to perform the

demolition, environmental remediation and asbestos

abatement of the 65,000m

2

(700,000 ft

2

) former

Merck Flint River Plant in Albany, Georgia, that began

production in 1952 and closed in 2007.

The first stepwas to implement environmental

and safety control methods designed to ensure the

safety of workers, the public and the environment. A

silt fence and gravel leaching systemwere installed

to ensure no contaminants left the property or entered

the Flint River.

The next stepwas to abate all environmental

hazards. The 100 acre site contained over 105,000

tonnes of contaminated concrete, blocking and

asphalt that was transported to local landfills using a

large fleet of trucks alongwith Brandenburg’s custom

engineered demolition trailers. All had to be properly

permitted and licensed to haul specific waste streams

- 500 tons of hazardousmaterial was delivered to

an incinerator in Texas, 5,000 tons of hazardous

material concrete wasmoved to Emelle in Alabama.

Several undocumented process lines full of a

hazardous product containing formaldehyde were

discovered. Brandenburg notified the owner and

formulated awork plan to safely drain and remove

these. All wastes were closelymonitored, tracked,

and properly documented. By identifying, testing,

and disposing of these contaminants, Brandenburg

eliminated the hazardous waste at this site.

Once abatement was completed, structures were

dismantled following optimal methods to segregate

thematerials. This phase included several multiple

story buildings, housing elevator shafts 15m (50 ft)

below ground, pipe racks, tank farms, offices, and

all underground utilities, foundations and basements.

There were 1,322 loads of scrap that generated

more than 13,500 tonnes of recyclablematerial.

Excavations of several 1.8m (6 ft) thick foundations

more than 9m (30 ft) deepwere removed.

The final stage was backfilling all excavations

caused by concrete removal. The project was

completedwithmore than 125,000man hours and

zero lost time accidents.

The assignment demonstrated significant

environmental conservation, community improvement

to health and safety, and a positive impact on the

quality of life.

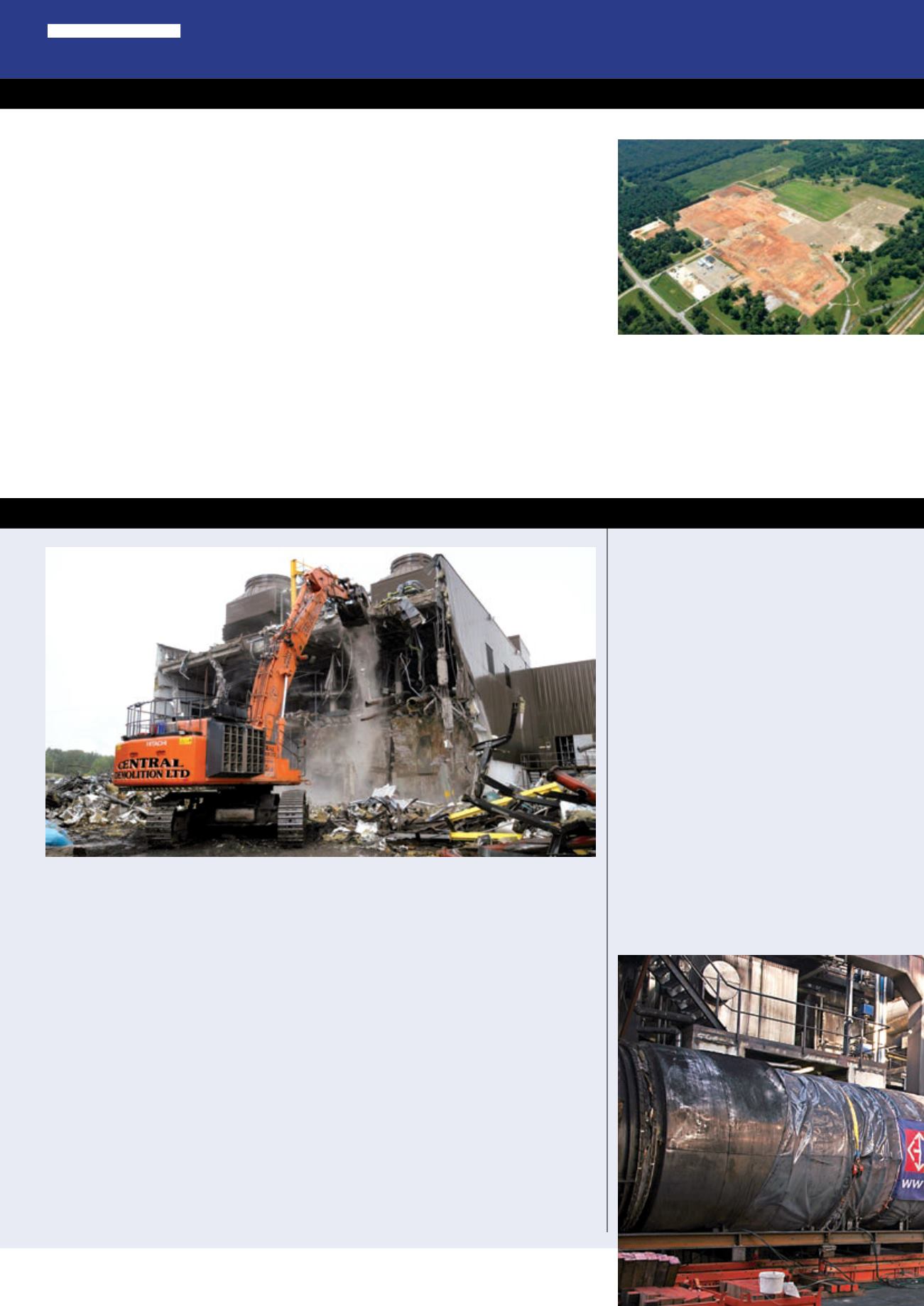

Central Demolition

FreescaleMotorola facility,

East Kilbride, Scotland

Central Demolition has been shortlisted for thework it

carried out at the 75,000m

2

(800,000 ft

2

) Freescale

Motorola plant in East Kilbride, UK. The site contained

a large number of bespoke steel-framed buildings that

had been added over a period of yearswhere required

to facilitate expansion byMotorola and then by

Freescale. The biggest difficulties ensued from the fact

that none of the buildingswere of similar construction

or of consistent height or feature. This resulted in

individual risk assessments andmethodologies

having to be developed for each, with each removed

successfullywith no incidents or injuries occurring.

The demolitionworkwas further complicated

by the existence of a testing facility adjoining the

demolition site that houses highly sensitive testing

equipment that could not be compromised under any

circumstances. To prevent damage to the equipment

Central organised and implemented a vibration

monitoring programme that demonstrated that

DDMDemontageBV

Cabot BVcarbonblackplant,

Rotterdam, TheNetherlands

DDM had been taskedwith the removal of two large

dryers at the Rotterdam site where Cabot BV produces

carbon black. The dryers are being replaced, with

the new units already being fabricated on site.

Themethod of removing the old and placing back

the new dryers was the challenge. After months of

contemplation about the best method to do this,

Cabot contacted DDM.

With an initially small team consisting of a

cost and technical engineer DDM took on the job.

Themain priorities for the client were safety, short

turnaround, very tight spaces and theminimisation

of disturbance to the operational plant. Another big

issue would be lifts over live process equipment.

Cabot and DDMworked out a detailed plan to

replace the dryers and a lifting and rigging company

were brought in. These became part of the team

that DDM lead, with the company responsible for

fabrication of the new dryers also involved in the

background.

All possible hazards were listed by DDM’s HSEQ

acceptable vibration levelswere not breached.

The site required extensive remediation activity

to keep it safe at all times and tomake it suitable for

future redevelopment. The network of stainless steel

and plastic pipework carried residual risks despite

prior cleaning. Central flushed out and visually

checked all pipes for sags and possible sites of

hazardousmaterials/substances.

Another major hazardwas having towork around

the phased removal of high and low voltage cables

duringworks on site until the supply to the adjacent

building could be diverted. The lineswere clearly

marked out and pointed out to all employees during

their site inductions to avoid accidents and because

it was of paramount importance that power to the live

building on-sitewasmaintained at all times.

Another example of a significant hazardwas

ground contamination. Some of the pits andwork

areaswere found to be contaminatedwith oil. To

resolve this hazard, these areas of groundwere

removed separately and carefully, and segregated for

cleaning and remediation prior to recycling.

WORLD

DEMOLITION

AWARDS2O14