45

d

&

ri

DEMOLITION AWARDS SUPPLEMENT 2014

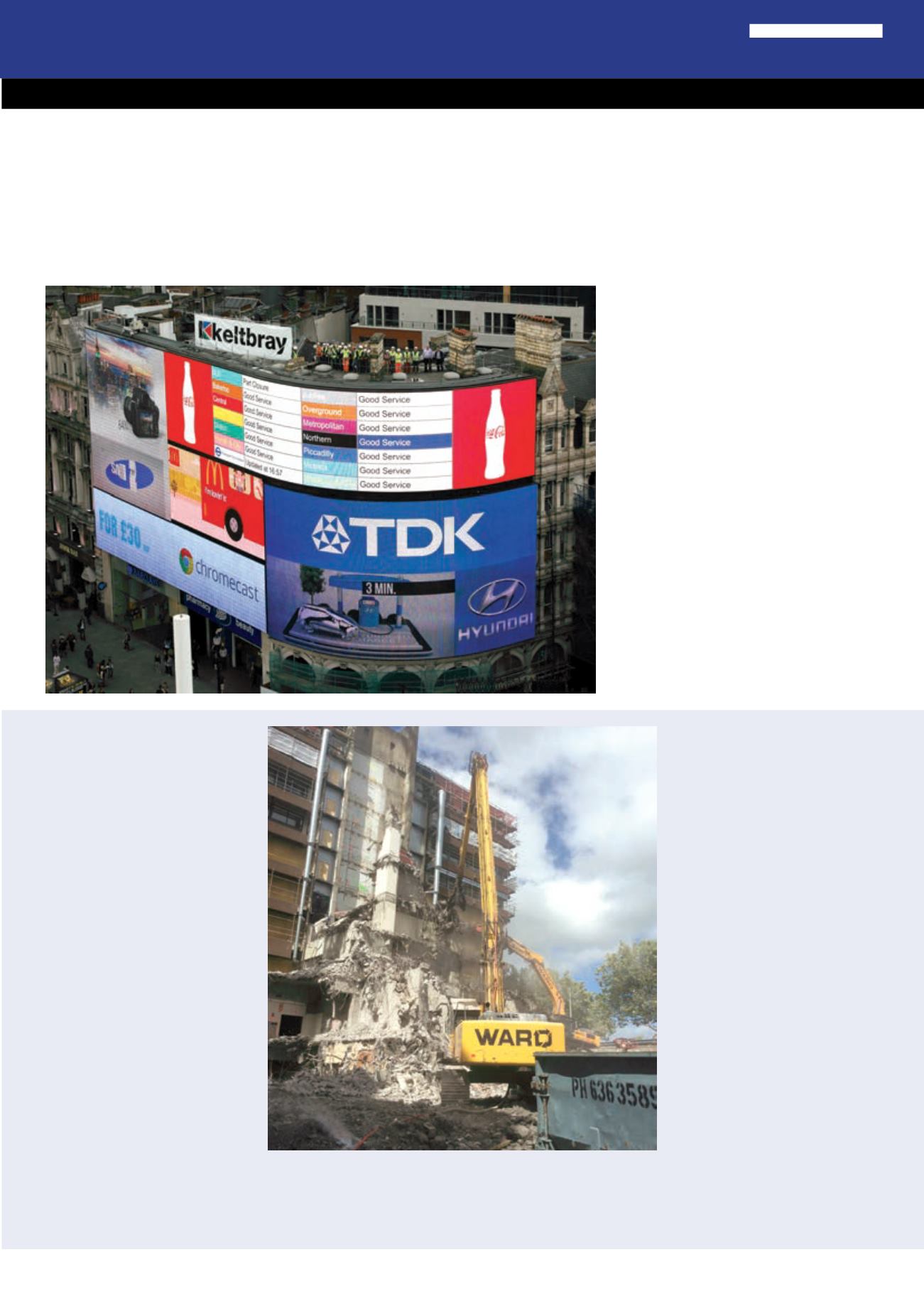

WardDemolition

Universityof Auckland

ScienceCentre

Building 302,

New Zealand

A roomful of radioactive Cobalt-60 that

could not be removed sitting directly

under the demolition site was just one

of many challengesWard Demolition

facedwhen it was contracted by

Fletcher Construction to demolish a 14

storey science education building at the

University of Auckland, New Zealand.

Situated in the CBD on the

intersection of a four-lane road and

amotorway slip road, the building

coming downwas still connected to

an adjoining education building. There

was also another multi-level campus

building 5m (16.5 ft) away andmore

than 20,000 students crossing through

the area daily.

The first jobwas to secure the

vault containing the Cobalt-60 against

damage and the potential escape of

radioactivematerial. After calculating

stress and vibration loads, two to three

layers of overlapping steel plates each 20mm

(0.8 inch) thick were laid over the 0.6m (2 ft)

concrete casement and a deflection plate laid over

the areawith soft padding underneath. All work near

the vault was carried out by hand and rubble above

crushed to reduce risk of breakthrough.

The tower was next. The top five levels were cut

and craned that then enabled a Komatsu PC600

with a 35m (115 ft) reach to remove

the remaining structure inmanageable

pieces.

Dust suppression protocols were

put in place, and pedestrian and traffic

management plans activated to further

reduce risk. Plywood hoardings around

the lower levels of themain building

were lined and battened to reduce noise

levels andwork began on separating the

two buildings.

The biggest challenge was that

the ‘live’ building, still attached, was

being used for teaching and conducting

scientific experiments sensitive to

vibration.

To keep vibration to aminimum,

the concrete wall connecting the two

buildings and the steel tie-ins were

removed using hand tools, leaving a

100mm (4 inch) separation between

the two structures. Even after separating,

machines andmethodology had to be

chosen carefully to reduce the impact

of ground vibration and on several

occasions work was halted until an

experiment was completed.

There were no injuries on the site, a challenging

project was kept under control and brought in on

time, and the client and the construction company

were happy with the result.

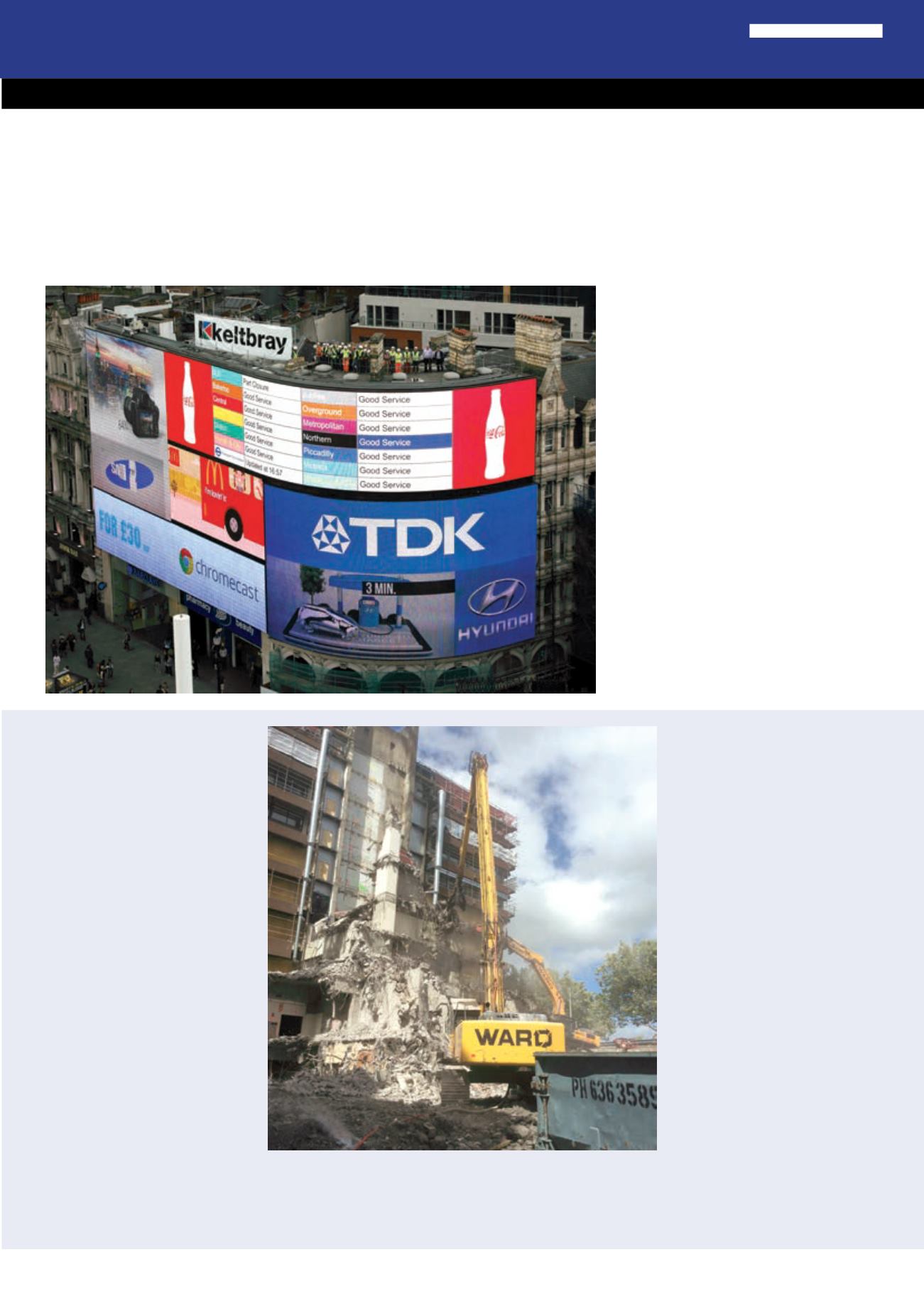

Keltbray

2-3Piccadilly,

London, UK

The complexity of the 2-3 Piccadilly project was

evident from the start. Given the condensed but yet

highly populated surroundings, the job facedmany

technical obstacles. Despite this, operations such

as carrying out effective and safe deliveries was

achieved and improved uponwhere possible.

The site was locatedwithin the Piccadilly Circus,

one of London’s busiest andmost recognizable

landmarks. It is placed on the corner of Shaftesbury

Avenue and Regent Street, both of which are

recognisable and densely populated streets and is

part of Westminster’s Core Central Activities Zones

(Core CAZ) andWest End Special Retail Policy Area.

The only existing area inwhich deliveries could

possibly come in and out fromwas located around

the rear of the site in Denman Street. All work on

site also had to take into consideration that two

live stores (Boots and Barclays) were still in full

operation below an area of the site.

The intentionwas to combine the two existing

retail units to create a large single unit that is opened

up internally with new consistent floor plates at

basement to second floor level. The floors from third

floor upwards remain unaltered. To achieve these

modifications, the existing ground, mezzanine, first

and second floor levels were demolished together

with the internal load bearingwalls. These were

then replacedwith a new steel frame comprising of

columns and beams that would support the existing

structure above the second floor together with the

new concrete floor slabs from ground to second floor.

The new steel columns were also supported on new

pad foundations installed below the basement.

A new external staircase on the second floor

rooftop areawas also constructed to provide an

alternative route of access.

With the site being such an iconic London

landmark it was crucial all relations with the public

were done in an appropriatemanner. For example

restrictions were in place to limit the amount of

noise created. Set hours were determined prior to

commencing to ensure that the effect on nearby

neighbours would be limited. Constant liaison

with all nearby businesses was also fundamental,

particularly given the nature of some of the

businesses. The project was delivered on time and

within budget.

WORLD

DEMOLITION

AWARDS2O14

URBAN/CONFINED SPACEAWARD

continued