international

construction

july-august 2013

QUARRYING

42

The big payback

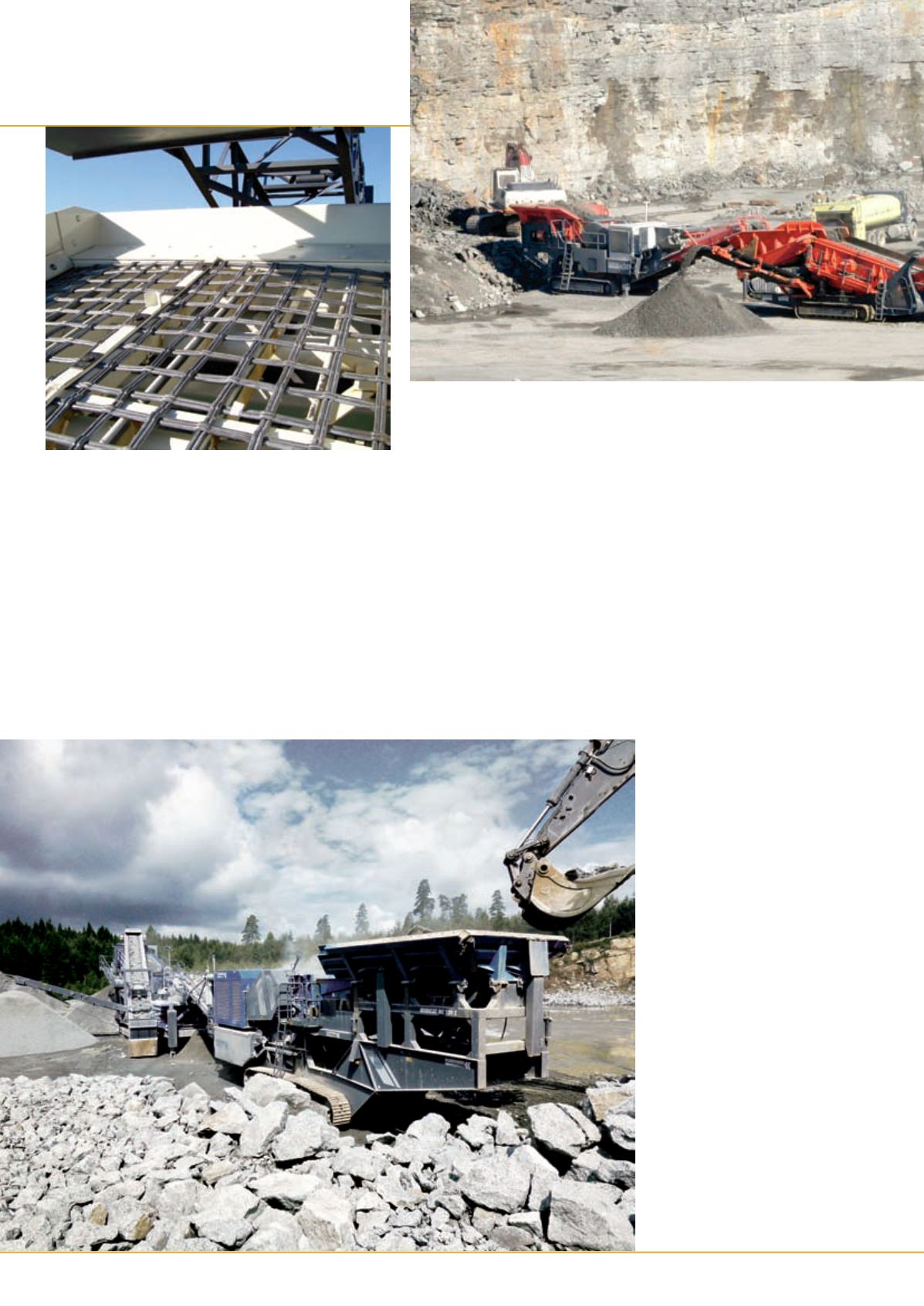

Major Wire says its Double-Weave screening media, which is constructed of

two, side-by-side, light-gauge wires, outperforms heavy-gauge single-strand

wire screens and perforated plates in high impact applications because it is less

susceptible to breakages.

“The C120 cavity is also very well suited to crushing

fragmented feed materials. Even difficult feed doesn’t block the

cavity. Therefore, we hardly need to use our hammer,” he added.

Sundvik’s three-stage portable crushing plant is kept running

for two 8-hour shifts per day. The C120 jaw is usually operated

with a 100 to 150 mm closed side setting, resulting in a capacity

of 250 to 300 tonnes per hour.

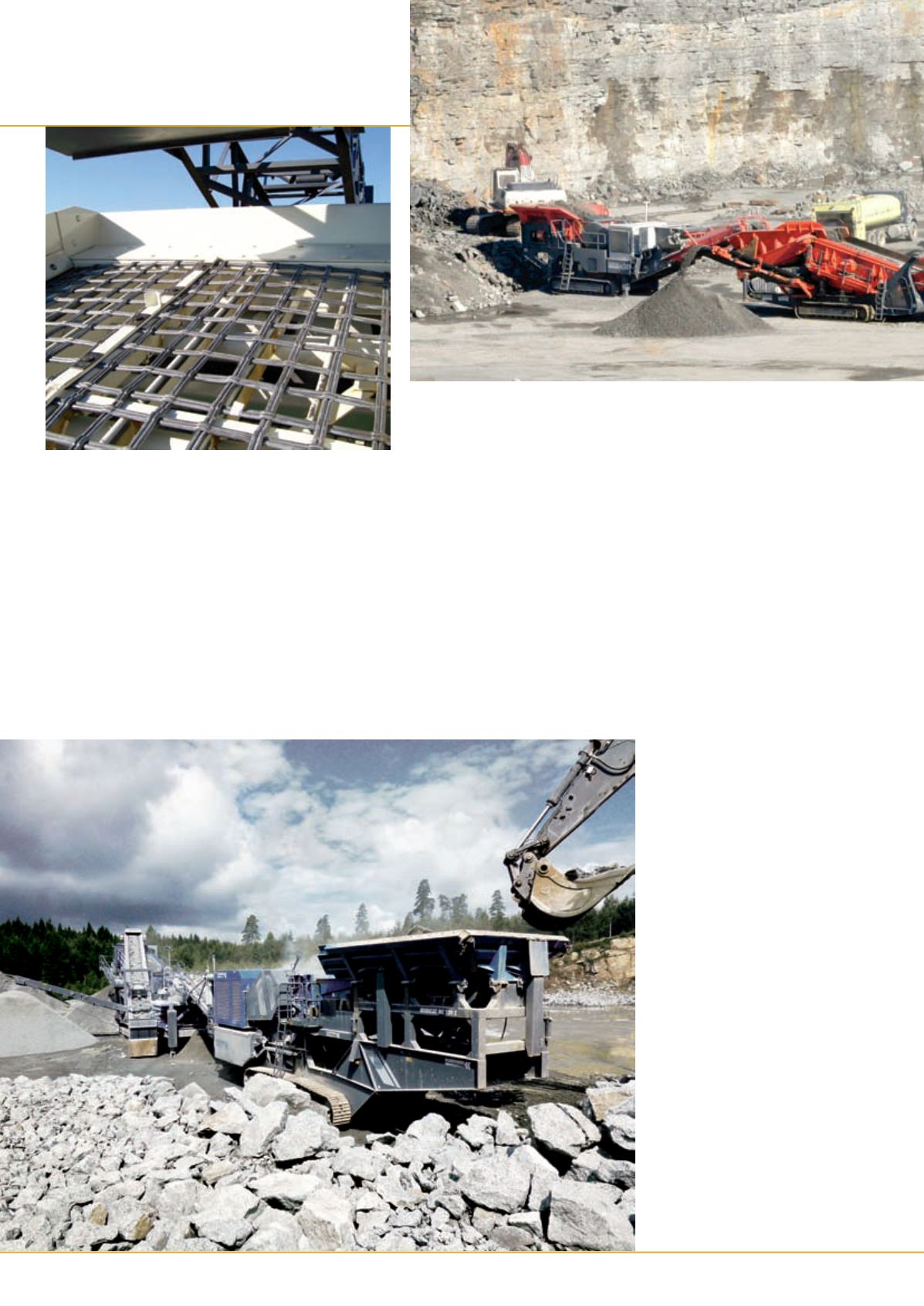

The Boda quarry near the small town of Vrigstad, Sweden,

meanwhile features particularly hard granite, with a compressive

strength of over 300 MPa in places. Crushing specialist TJ Gräv

chose a Kleemann Mobicat MC 120 Z mobile jaw crusher as the

primary unit with a Mobicone MCO 11 S mobile cone crusher

for downstream work.

The primary stage reduces the feed material, which can be up

to 1 m long, down to a 0 to 200 mm stream. The cone crusher,

followed by a three-way screening system then produces 0 to

8 mm, 8 to 14 mm and 14 to 22 mm products. The plant is

producing 1,000 tonnes of material per day.

Tomas Johansson, owner of TJ Gräv AB, said the Kleemann

machines were was well-suited to the application. “Both plant

units have a diesel-electric drive system, which has a very

favourable effect on fuel consumption. Not only that, they are

built very sturdily,” he said.

It is also significant that TJ Gräv chose mobile crushing and

screening equipment, which is a clear trend around the world

due to the flexibility such machines can offer.

Mobile equipment

Hamilton Aggregate was founded in 2006 at Bonds

quarry, located in Clinton, Arkansas, US. From the outset

the company opted for mobile crushing

and screening equipment that could

be moved to the face to crush material

without the need for hauling it, and

which can be transferred between

quarries.

Today the set-up consists of a Sandvik

mobile QJ341 jaw crusher, a QE440

scalper, a QA450 triple deck screener and

an Extec X44 cone crusher. Extec is now

part of Sandvik.

As company owner, Edward Hamilton

said, “These mobiles are quality machines.

They provide us with lower operating

costs and high production for their size.”

A further quarry, Greers Ferry, operated

by the company in Higden, Arkansas,

was acquired to supply aggregates to a

nearby bridge project.

The constant steady supply required

from the Greer Ferry quarry emphasises

the need for a reliable aftermarket

support.

“The equipment has proved to be

highly reliable, but after discussing our

A Kleemann Mobicat MC 120 Z primary

jaw crusher tackles 300 MPa Swedish

granite at the Boda quarry near

Vrigstad.