39

july-august 2013

international

construction

QUARRYING

The big payback

Quarry workhorse

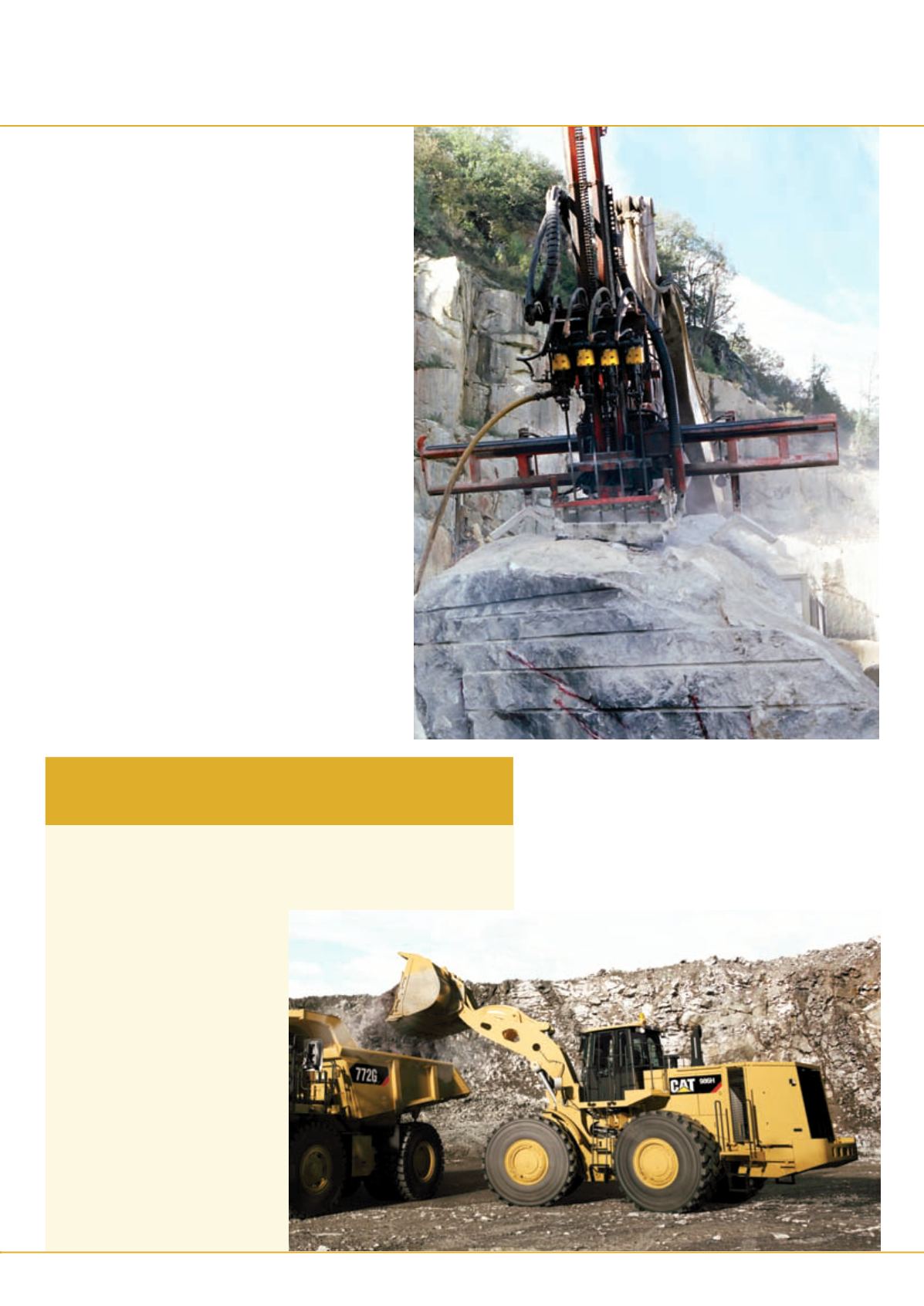

New loader for lesser regulated markets

>

T

he new Cat 986H wheeled loader has been designed for quarry applications, and it

is a model made purely for lesser regulated markets, outside of Europe, Japan and

the US. With bucket capacities ranging from 5.3 to 6.1 m

3

, the 305 kW machine

features a power train with proven Cat

components, a load-sensing hydraulic

system, heavy duty frames and loader

linkage, and a safe, comfortable operator

station.

Using solid steel lift arms designed to

absorb loading stress, the 986H Z-bar-

type loader linkage generates powerful

digging and lifting forces and provides

excellent visibility to the bucket cutting

edge and surrounding work area. Lift

arms are available in both standard-

lift and high-lift configurations to

accommodate a range of haul trucks.

Equipped with standard linkage, the

986H can load 38.6 tonne capacity Cat

770G trucks in four passes. With high-lift

linkage, it can five-pass load the 47.7

tonne 772G and six-pass load the 56

tonne 773G.

“We do have our own maintenance staff to keep the machines

running, but Riverlea has always been there to look after us

when we need them,” she added

Supplied in standard specification, the equipment is already

delivering a boost in productivity for the company. With

a continued growth in demand for aggregate throughout

the region, Ms Phillips says the company will be looking for

additional machinery before long.

It is often the case that new machines come with new features

that can help productivity and safety. Doosan for example has

launched several new features on its DA30 and DA40 ADTs

aimed at doing just this.

A levelling meter uses rotation sensors installed on the front

and body of the truck to tell the driver via clear graphical

readouts whether or not it is safe to drive forward and to stop if

there is a danger of turning the machine over.

On the productivity side, a new payload and cycle count meter

uses load sensors to provide an immediate readout on the cab’s

control monitor of the payload with an accuracy of +/- 5%.

The load is registered and counted in the vehicle control unit.

Double counting is avoided because the system will not log

another load until the truck has travelled more than 50 m or

after a timeout of 3 minutes.

The data can be downloaded to a USB memory stick or sent

as an attachment. It is in Wordpad format and can be identified

and tracked by assigning it with a serial number.

Meanwhile the new Economy mode on the trucks is designed

to cut fuel costs by controlling engine speed. Doosan says the

system comes into its own on long haul roads where a new

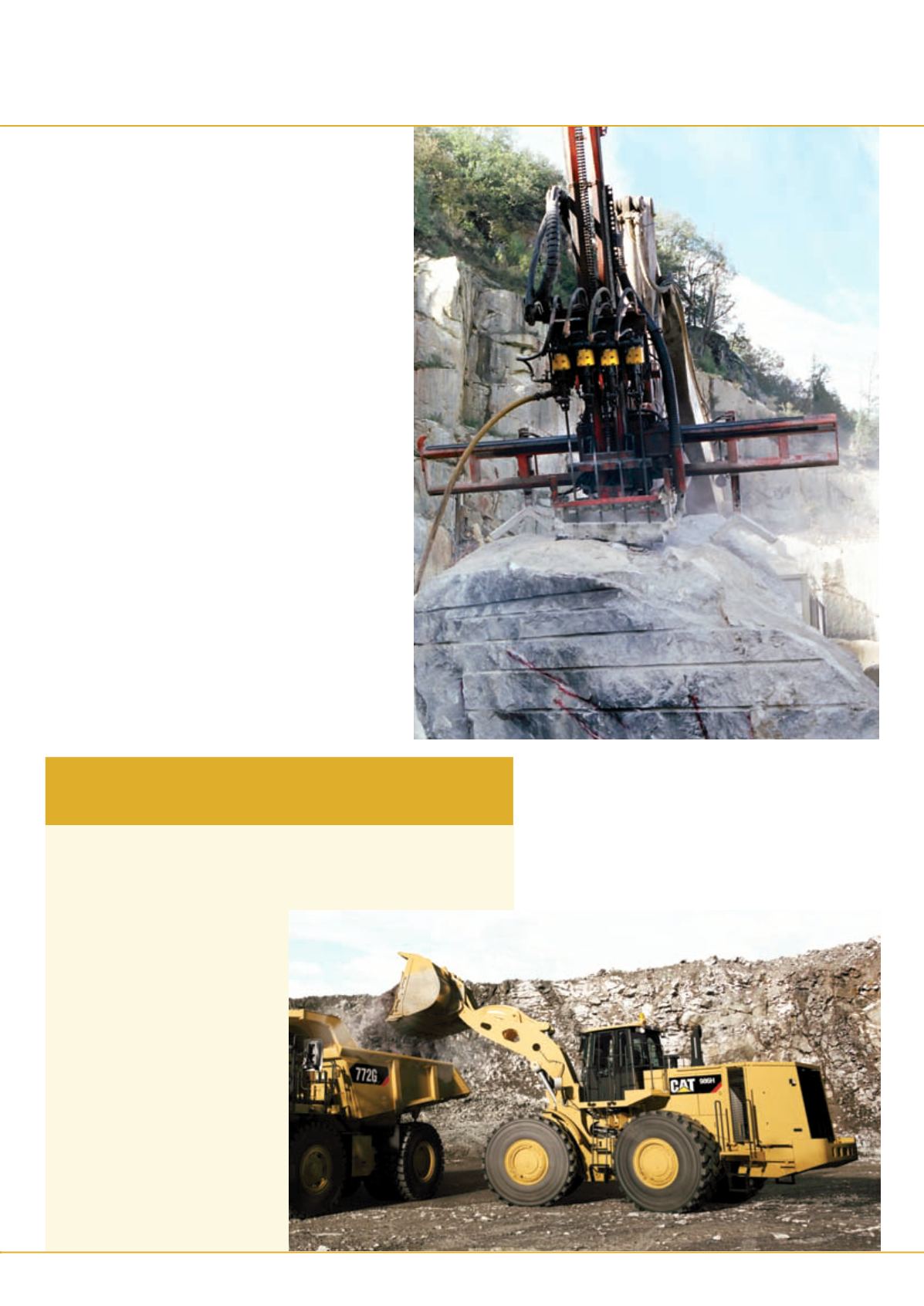

New BBC 34 DSI rock drills from Atlas Copco

are delivering a 5 db(A) reduction in noise

for quarries in Portugal’s Parque Natural das

Serras de Aire e Candeeiros national park.

powertrain and electronic control allows the engine to run at

the best point in terms of power and torque.

Quiet drilling

And there can be improvements in other important areas such

as noise and environmental performance. For example, Atlas

Copco has supplied limestone quarries in the Parque Natural

das Serras de Aire e Candeeiros national park in Portugal with