international

construction

july-august 2013

QUARRYING

36

The big payback

>

Surowce Skalne – is believed to be

Poland’s largest producer of aggregates.

The facility can produce 5 million tonnes

per year in grades suitable for both road

and rail projects. Bulk deliveries are

made by rail in a 60 km radius of the

site, and the quarry’s location near the

E67 highway also allows for efficient

road transport of materials.“This is the

first Hitachi that I’ve worked with,” said

quarry manager Janusz Rydz, “but from

what I’ve heard in the market, Zaxis

excavators are very reliable and durable.”

He continued, “We hope that the ZX670LC-5 will enhance

the level of productivity on this site. Our aim is to reduce

the cost of every tonne of stone extracted. To do this, we are

renewing our fleet of construction machinery and in this case

we believe that we have found the best solution.”

Machine operator Boleslaw Gazda estimates the ZX670LC-5

excavates and loads some 600 to 700 tonnes of materials per

hour, depending on the size of the rocks.“The Hitachi provides

a very stable platform – even working in the

challenging conditions of this quarry –

and the loading cycle is good,” he said.

American return

Bell establishes US distribution & support

B

ell Equipment is returning to the US market after more than a decade, offering

customers the choice of another supplier for ADTs. The company is currently setting

up a distribution network to handle sales of its existing D-Series and forthcoming

E-Series trucks.

The return is linked to the end of a licensing agreement with John Deere, which saw Bell

providing the truck technology and Deere manufacturing and distributing machines under

its own brand. Deere has now developed its own range of ADTs.

Bell’s push into the US market will be headed by a new sales company, Bell Trucks

America (BTA), in Houston Texas, which has already appointed several dealers in the US.

This company is a joint venture between Bell and other investors, and it will be supported

by a Bell wholly-owned subsidiary, Bell Equipment North America (BENA) for factory

sales, after-sales support and technical advice. This will extend to Canada, outside BTA’s

territory.

BENA is headed by Neville Paynter, who previously ran Bell Equipment’s operations in the

UK. “The Bell brand is founded on providing strong reliable machines, backed by strong

reliable support. We believe we have the right team and business model in place to deliver

these qualities to the North American market,” he said.

“It’s also fast and precise thanks to the simplicity and efficiency

of the hydraulic system.”

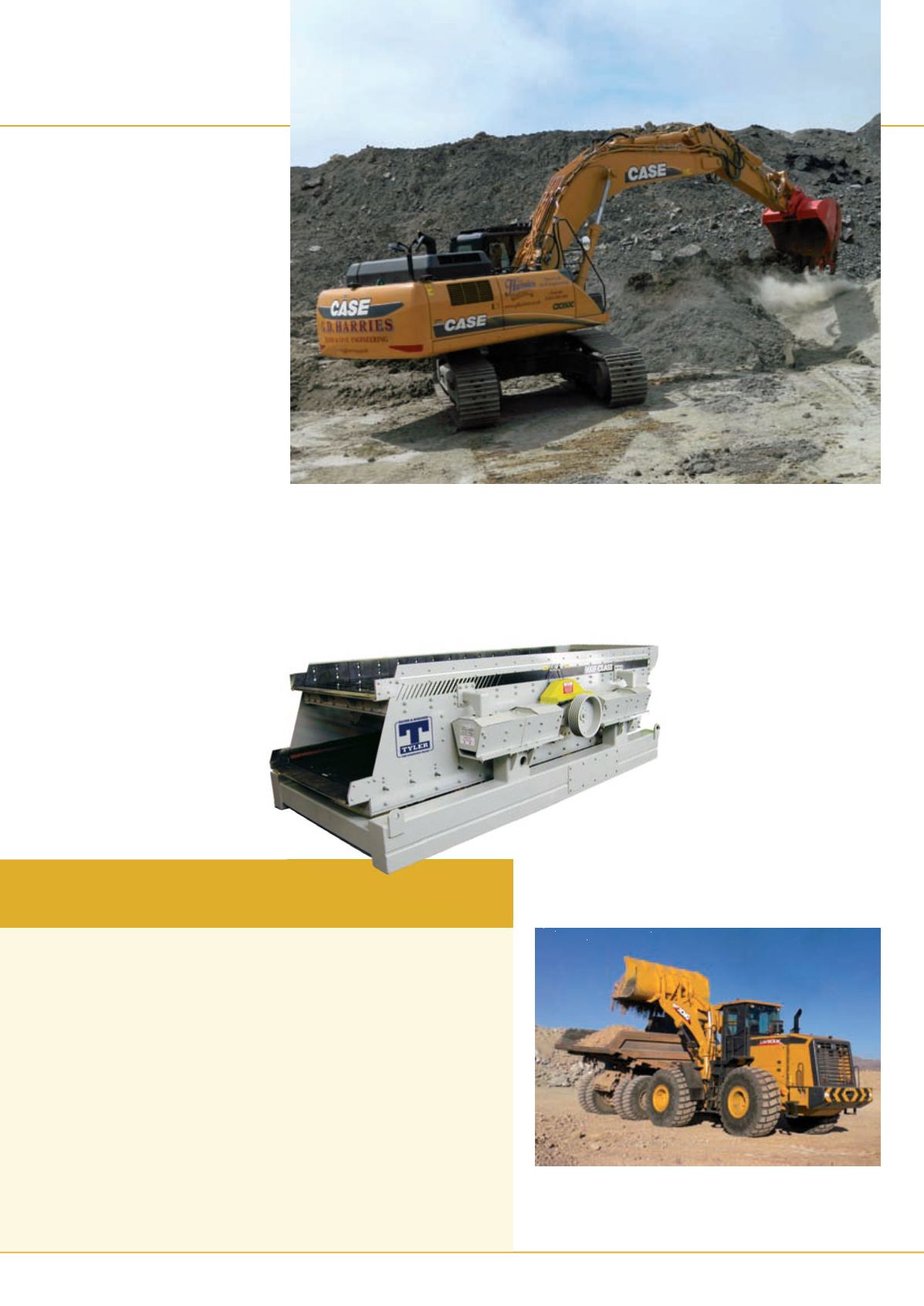

Meanwhile in the UK, quarry operator and civil engineering

contractor GD Harries & Sons is expanding its business with

the addition of four new Case machines, supplied by local dealer

Riverlea. Based near Narberth in West Wales, UK, the last 18

months has seen Harries acquire four granite and two

limestone quarries. It also runs three

concrete production plants and three

asphalt facilities, and has expanded its

interests into road surfacing and other

civil engineering contracting operations

alongside its quarries.

The two new two CX350C crawler

excavators, 1021F wheeled loader and

821F loader replace existing machines

as part of fleet renewal plan. The 35

tonne CX350C excavators are now the largest

machines in the Harries fleet and, along with the two

wheeled loaders, will contribute to an increase in production

levels within the quarry operations.

“We did price other equipment but Riverlea was able to put

together the best deal for us in terms of price and quality,“ said

Harries business manager Janet Phillips.

XCMG has supplied a 250 kW LW800K wheeled loader to a

quarry site in the Gobi desert, where the company says it

continues to perform and provide impressive fuel efficiency

despite temperatures that can reach 50° C.

Business expansion and a drive

for greater efficiency prompted

GD Harries & Sons to buy two new

Case excavators and two loaders

for its quarry operations in Narberth

in West Wales, UK.

W.S. Tyler has launched a 4 ft (1.22

m) wide version of its F-Class

vibrating screen, expanding

the lower end-of the range.

The double eccentric provides

consistent forces, which helps

reduce blinding and pegging, even

when screening sticky material.