35

july-august 2013

international

construction

QUARRYING

The big payback

>

mountains, the terrain is hard to negotiate especially given that

track gradients can be 20° or more.

“We are dealing with a lot of steep hills,” said Mike Pratchett,

president of Vertex. “We also have to deal with almost two-

mile (3.2 km) haul cycles and rain for 10 months of the year,

resulting in muddy slippery slopes. You could say we have tough

working conditions to contend with almost all year round.”

Vertex excavates clay and till at the quarry as well as clearing

logs and over-burden, taking a role in waste management and

working with the provincial and local authorities on water

management and environmental issues.

The company has an all-Volvo fleet

to tackle its work in these difficult

conditions, with a pair of Volvo

EC360B excavators, five Volvo A25D

articulated dump trucks (ADTs) and a

Tier 4-compliant Volvo EC380D crawler

excavator on site.

The EC380D was one of the first

delivered in North America. “When

the machine arrived, we added a few

additional accessories to it, such as the

larger 60 in (1,524 mm) wide digging

bucket, a hydraulic thumb and, because

our contract calls for log clearing, we

added the falling object protective

structure (FOPS) to guard the cab from

falling debris,” said Mr Patchett. “It’s a

tremendous machine, plenty of power, great stability, superior

lighting and a cab full of creature comforts. Even in this till and

clay that has been compacted for centuries, the excavator has

allowed us to improve our cycle times.”

He is also a fan of the Volvo ADTs, something that clearly

runs in the family. “My dad started his business using Volvo

machines, and I’ve been around them all my working life.

When it came time to buy my own trucks, I wouldn’t consider

any other brand. Because of the efficiency of the transmission

retarders and exhaust brakes, we haven’t had to replace a single

brake pad,” said Mr Patchett.

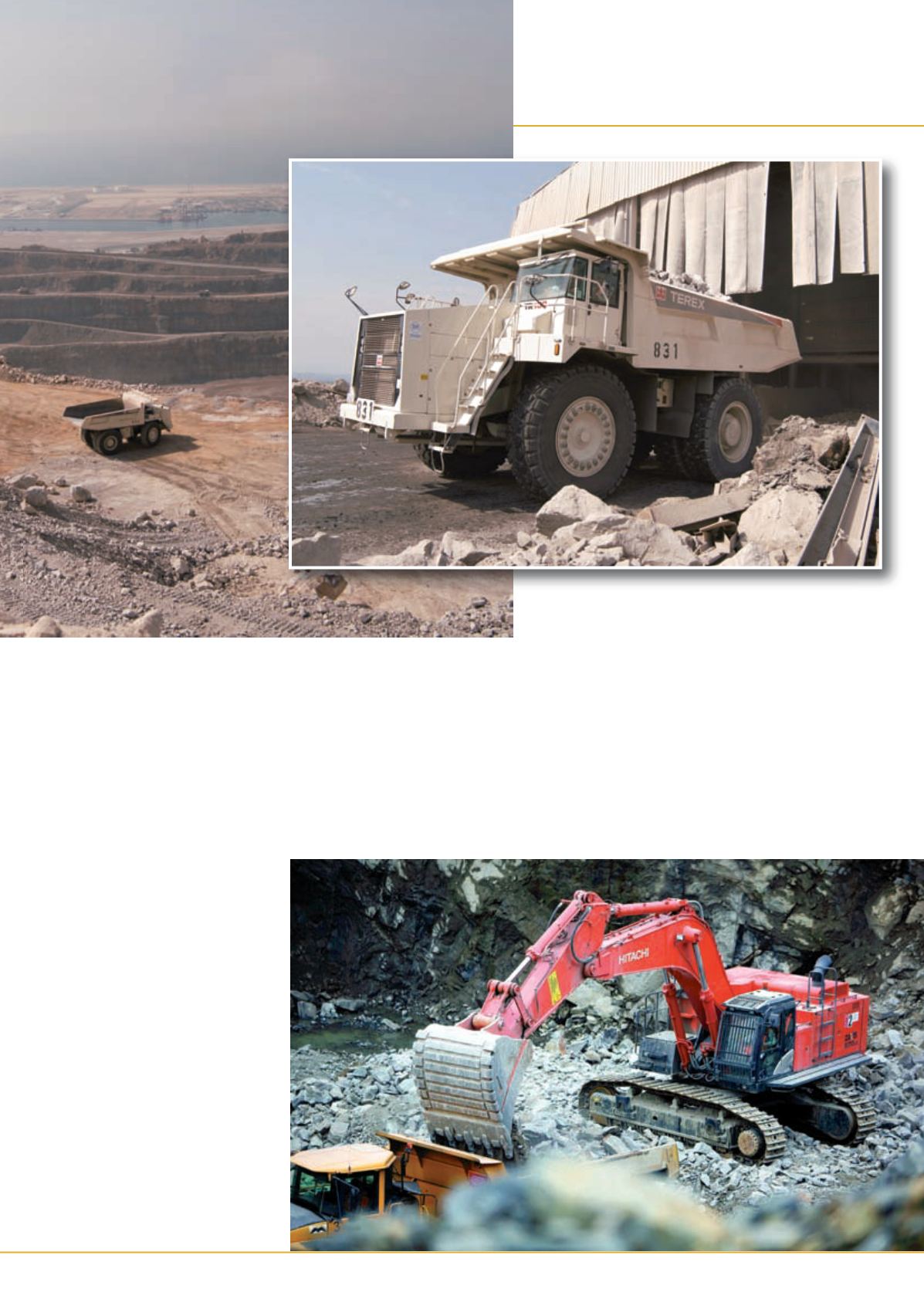

Further up the weight classes, January saw Polish aggregates

producer DSS Group acquire a new 70 tonne class Hitachi

ZX670LC-5 for its quarry at Pilawa Górna in Lower Silesia from

local dealer Tona. The DSS Group – owned by Dolnośląskie

Polish quarry operator DSS Group

has bought a 70 tonne class

Hitachi ZX670LC-5 with the aim of

reducing the cost per tonne of its

Pilawa Górna quarry.

>