TECHNOLOGYUPDATE

OPERATORAIDS

54

ACT

JUNE 2014

With increasing safety concerns and adherence tomore stringent

regulations in crane operation, the loadmoment indicatormarket

has expanded.

John Skelly

reports on updates in LMI technology.

hoist drum rotation indicator compliance,

without theneed for video cameras,

mirrorsorother temporaryalternatives.

UtilizingCAN J1939, thedevice is able

to interfacewith theLMI or telematics

systems to further aidoperating in safe

working conditions. Byacquiringdata

on thehoist’sduty cycle, operators and

managers canmore accuratelypredict

maintenance requirements thus extending

the lifeof the equipment and reducing

costlydowntimeduring time sensitive

operations.

TheRayco-WylieSystems team

presented its latest technology, the i4510

all-in-one rated capacity indicator,

atConExpo inLasVegas inMarch.

Designed toaccommodate all typesof

cranes formanufacturersworking in

the constructionoroffshore industry,

the i4500 is thenewgenerationof rated

capacity indicators. It offersmore

complete integrationwith the crane

and the ability tomonitor advanced

operational parameters, suchasboom

sequencing, outriggermonitoring, range

limitingandwind speed. This i4500has

the capability to centralize the safety

information, enginedataand camera

images all onone clear, full colordisplay.

LSI-Robway isoffering the crane and

forward indeveloping

its iSCALE control

systemby introducing

theqSCALE l2–a

management solution

for loadmoment devices

onmobile cranes. The

qSCALE l2 integrates

visualizationand load

moment indication inonedevice.

Using theqSCALE l2Configuration

Tool, programming isnot necessary.

CoDeSys knowledge isnot required,

enabling the configuration functions for

applications tobe executedby the system

integrator. The easy configurationof the

qSCALE l2alsoprovides cost-effectiveuse

in the areaof retrofitting, the company

said.Numerous cranesof olderdesign can

be consequentlyupgraded.

What’s new?

TWGdeveloped the INTELLIGUARD

IIHoistMonitoringSystemwhich

integrates adrum rotation indicator and

last layer indicator intoonemonitoring

system. This solutionallowsoperators

andmanagers toachieveOSHA-required

T

he sky is the limitwhen it comes

to loadmoment indicators.

Choosingone canbedifficult

consideringhowmanyoptions are

available. Sowhat shouldbe considered

when investing inanLMI onanew

craneor replacingoneonanolderunit?

Considerproduct support first.

“Downtime inour industry comes at

suchahigh cost, findinga company that

offers global support 24hours aday, seven

days aweek, inmultiple languages should

be amajor factor indecisionmaking,”

saidMikeBrooke,NorthAmerican sales

manager, LSI-Robway. “Users shouldalso

considerwhichLMI system isbest for

their specific applicationbasednot only

onwhich factors theywant tomonitor in

addition to theweighing system, but also

basedonhow theywant toview theirdata

andhow theywant their equipment to

respondwhen there is an issue.”

New features inLMIs run thegamut

from colordisplays that aremore legible,

variousweather resilientmaterials such

as stainless steel foroffshore andharsh

environments, compliancewith increasing

global safety standards, telematics

integrationandOEM-proprietary

controllers anddisplays. Sowhat’snew?

Hirschmann tookanother step

LMI technology

steps up

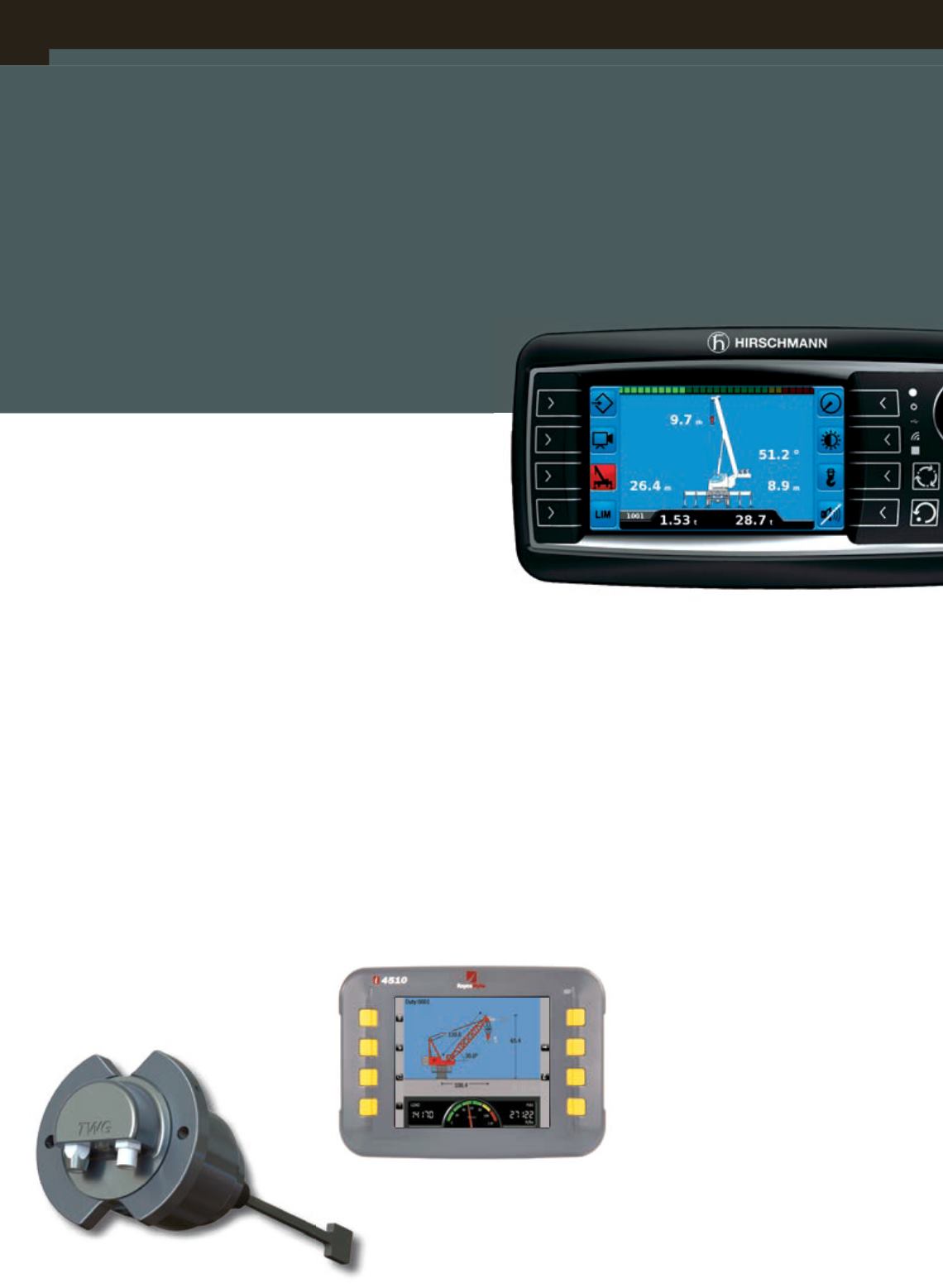

The qSCALE l2 integrates

visualization and loadmoment

indication in one device.

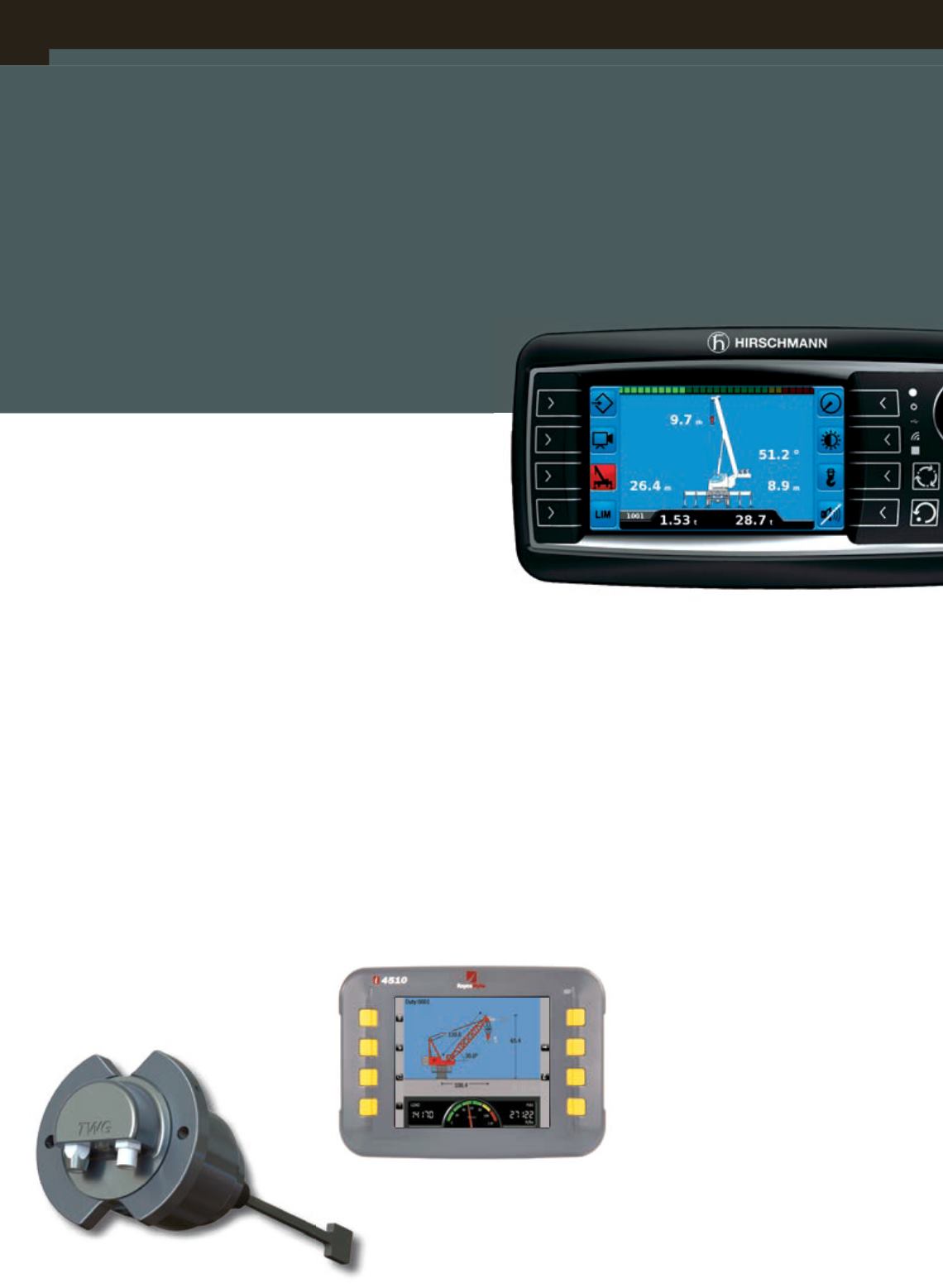

The INTELLIGUARD II HoistMonitoring

System integrates

a drum rotation

indicator and last

layer indicator

into one

monitoring

system.

The i4510 all-in-one rated capacity indicator

is designed to accommodate all types of

cranes for manufacturersworking in the

construction industry.