66

SEPTEMBER-OCTOBER2014

d

&

ri

IN ACTION

OilQuick

time for

AR

A

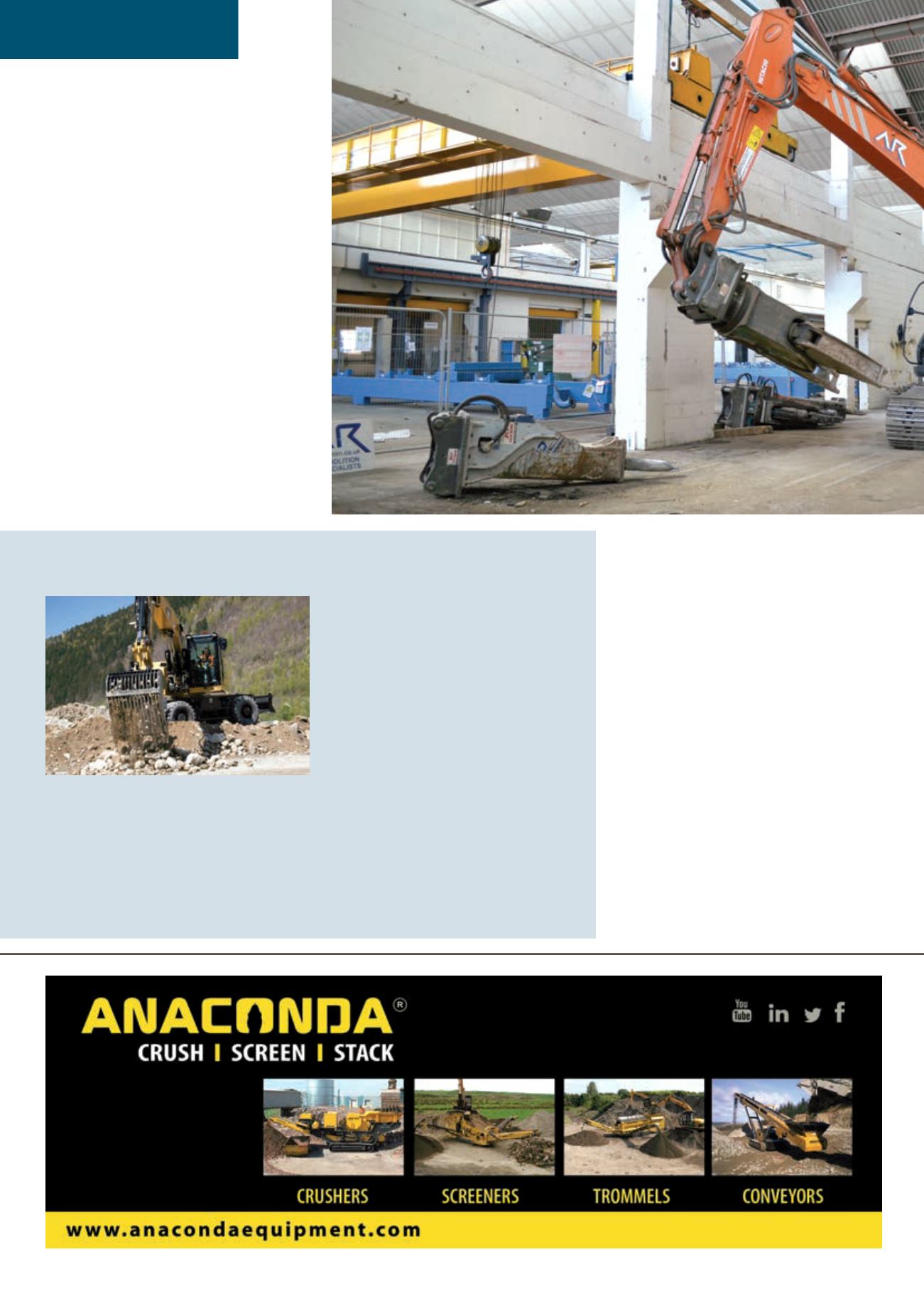

tBridgnorthAluminium in

Shropshire,Nuneaton-basedAR

Demolition faced the challengeof

internal demolitionof a400m (1,300 ft) by

10m (33 ft)wide aluminium lithography

stripproduction linewhereheight restrictions

meant that the largestmachine that could

beusedwas a20 tonne excavator. Thework

involved thebreakingout of a strongly

reinforced concretemezzanine ceiling at 10

mwhile retaining the externalwalls of the

structure. Theworkwas further complicated

by theneed to remove several heavily

reinforced concretebases that protruded from

the floor byup to2m (6.6 ft) to allow further

access into the structure.

With access so tight and compact, theonly

logical sequence for thedemolitionwas to

pulverise, shear andbreak alternately in small

sections,whichmeant frequent attachment

changes. The first stageof thework saw the

useof aVTNFP24 concretepulveriser to

remove theheavily reinforced concreteof

themezzanine floor andbring it down to

ground levelwhere itwas furtherprocessed

into smallerpieces and rebar removed.As the

rebarwas over 25mm (1 inch) thick itwas

not possible tobundlewith thepulveriser.

Theoperator therefor changedover to aVTN

MT20multiprocessor fittedwith steel jaws to

cut the rebar intomanageable lengths. Itwas

thennecessary to swap to a sortinggrab to

load the rebar into a scrap skip for recycling.

Thebroken concretewas left on the floor so

the excavator could track forwardonto the

next sectionof thebuilding.

When facedwith the first raised concrete

platform aFurukawaF27XPhydraulicbreaker

wasused tobreak into this base andmake

room toproceed into thenext stage to repeat

theprocess over again.

Caterpillar has introduced two new

wheeled excavators, the 19.7 tonne

M318F and 21 tonneM320F, which it

says havemade use of extensive customer

feedback during their design. Heading

the customer wish list were initial quality

and reliability, low operating costs,

operator comfort and safety, simplicity of

operation andmaintenance, durability and

environmental friendliness.

Bothmachines are powered by a Cat

C7.1ACERT Tier 4 Final/Stage IV diesel

delivering 126 kW (169 hp) and retain the best features of their predecessormodels,

including the Cat Smartboom, ride control, load sensing hydraulics, dedicated swing

pump, hydraulically driven cooling fan, large working envelopes and configuration/work tool

versatility.

The exterior has been given a completely new styling, including a new operator’s cab with

greater pressurisation, larger door with increased glazing, newwindowwith parallel wipers,

new rain visor and light protectors, a larger skylight and a standard rear view camera with

a separate in-cabmonitor.

Cats onwheels