IN ACTION

An OilQuick coupler is allowing ARDemolition

to rapidly and easily switch attachments

to process differentmaterials during the

demolition of an aluminium production line

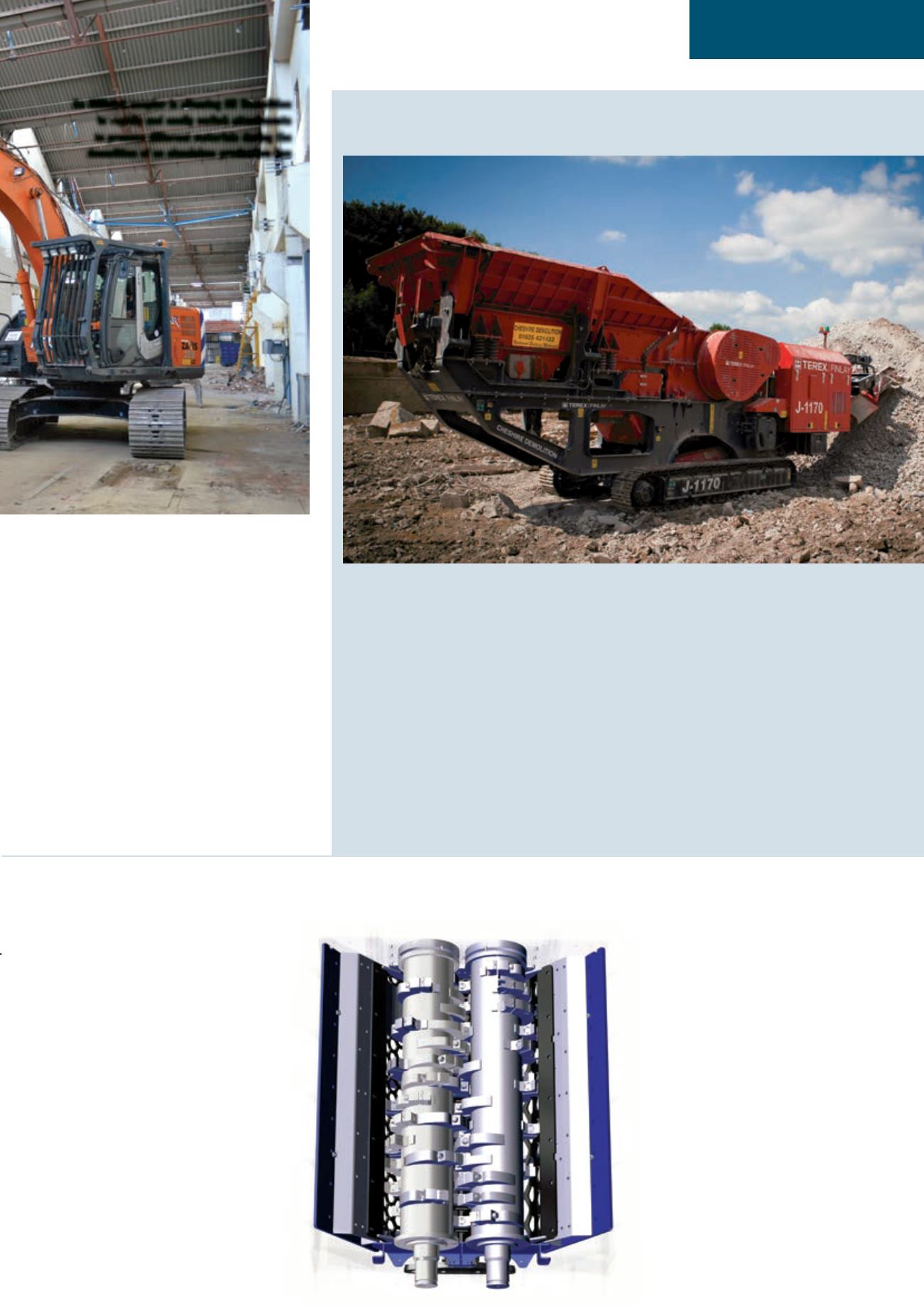

New jaw at Cheshire

Macclesfield, UK, based Cheshire Demolition has recently expanded its crushing capabilities

through the addition of a Terex Finlay J-1170mobile jaw crusher supplied by dealer Finlay

Central, following on from the acquisition of a J-1160 jaw and an 883 screen from the

samemanufacturer. The company has one of the largest reclamation yards in the north-

west of England and offers the full line of demolition services as well as skip hire.

The company originally bought the newmachine for use at its yard, but now it is also

used on site. Most recently, it processed 15,000 tonnes to deliver Class 6F2 product at

a rate of 200 tonnes per hour that will be used for ground restoration on site tomake it

suitable for redevelopment.

The J-1170 uses a hydrostatically driven jaw chamber that Finlay says delivers high

capacity with large reduction ratios. Its configuration can be set up specifically for

processing construction and demolition waste, or for use in quarrying applications. It also

features a heavy duty variable speed grizzly feeder and integrated prescreen that the

company claims delivers high production throughput in demolition and recycling applications,

as well as inmining and quarrying.

The Terex Finlay J-1170was initially acquired for yardwork but nowmoves from site to site aswell

The solution for these rapid tool changes

came in the shapeof theOilQuick system.

OilQuick is an automatic coupler that permits

hydraulicwork tools tobe connected and

disconnecteddirectly from thedriver’s cab,

allowing theoperator to changebetween

variouswork toolswithin seconds.

ARDemolitionmanagingdirectorRichard

Dolman commented thatwhereas they

wouldusuallyneedmore thanonemachine

on site, all fittedwithdifferent attachments

to carryout ademolition contract, only

onemachine isnow required. In terms of

financial gainsRichard said that this offers

themain advantage since thismeans lower

fuel, servicing andmaintenance costs.AR

Demolition isnow looking to the futurewith a

further investment inOilQuick for its fleet of

larger 40 tonnemachines.

■

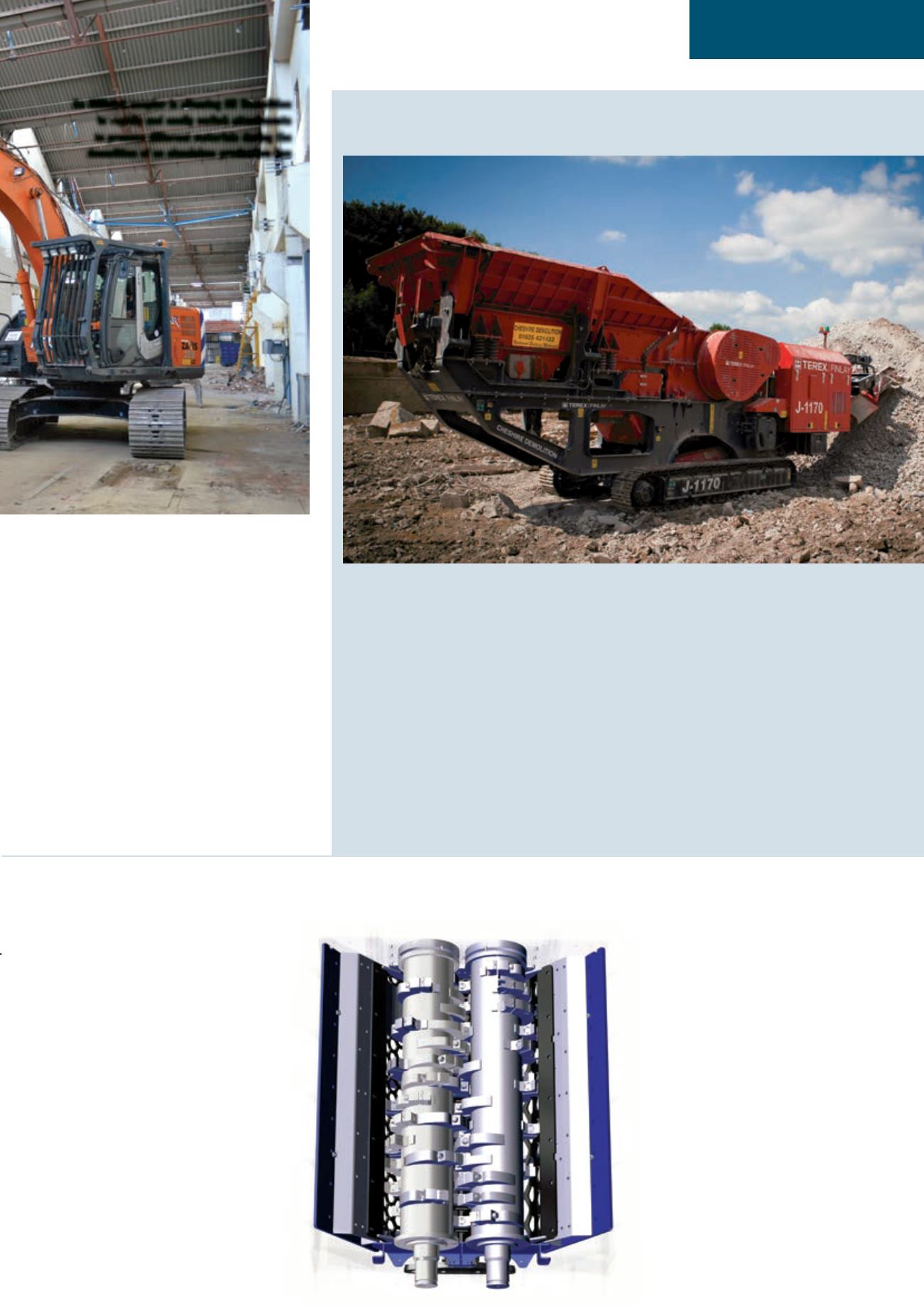

Shredding in one pass

N

orthern Ireland-basedEdge

Innovatehas introduced anew

basket system for its Slayer

XL shredder that allowsmaterial tobe

shredded to the required size in just one

pass.Available in sizes from50mm (2

inch) to250mm (10 inch) depending

on customer requirements, the system

canbyquickly removedor exchanged for

different aperture screens.

Edge’s Slayer canbedeployed

inprimaryor secondary shredding

applications becauseof its robust

design and resistance todifficult-to-

shredmaterials. TheXL range canbe

suppliedwithup to12different shaft

configurations to allow it tobeused

across awide rangeof applications.

Trampmetal cycles and intelligent load

sensingpreventsdamage and resulting

downtime.

Thenew shredding chamber

configuration comeswithbolt-on tools

with two cutting edges (doubling tooth

life), heavydutypipeunit shafts and

optional toothbreaker bar. Thenew

cutting edges on thebolt-on tools enable

theSlayerBasket System toboth cut and

shred. These characteristics allow it to

processdifficult tohandlematerials such

as carpets, tires andmattresses at ahigh

throughput capacitybut at low engine

output.

■

The basket system for Edge Innovate’s

Slayer XL shredder is availablewith

apertures from 50mm to 250mm

67

d

&

ri

SEPTEMBER-OCTOBER2014