24

MAY-JUNE 2015

d

&

ri

ATTACHMENTS

Special

service

Mutley Plant Service Ltd of Kent, UK,

is a specialist in themanufacture and

supplier of demolition attachments and

excavator modification, and has recently

been commissioned by several major

UK demolition contractors for bespoke

concrete pulverisers.

It has specially designed amechanical

pulveriser for Brown &Mason to suit

a Komatsu PC800 in the shape of a 6

tonneMPP 85 that offers a crushing

force of approximately 100 tonnes. The

new tool is being used for the stripping

out of the general utilities of a 1960s

vintage coal-fired power station, including

dealing with large cable tracks, smaller

pipes and smaller metal structures.

Mutley developed and produced the

attachment using a special manufacturing

process specifically to allow the pulveriser

to withstand the rigours of metal ripping,

tearing and pulling. Due to this unique

design, the crushing performance has

been enhanced over traditional pulverisers

and speeds up the process compared

to the normal methods of shearing and

cutting of internal lighter materials.

This gives Brown &Mason a versatile

attachment to strip out the internal

infrastructure of the power station.

In addition, Surrey based contractors

Wooldridge Demolition previously

purchased a smaller Mutley MPP 65

mechanical pulveriser to suit a Hitachi

ZX650 for more traditional concrete

crushing and on the back of this has

placed an order for a secondMPP 85 to

complement the its recent acquisition of a

Hitachi ZX850 excavator.

manufacturers that donot compete against

eachother. The success of thisUK approach is

another reason for his feelings of optimism.

Louis saidof developments in the sector:

“I think there are twoways of looking at our

industry. Rotar talks a lot about our improved

hydraulic infrastructure, whichmeans our

competition are all shouting about boosters

and suchbutwhatwe aredoing is using50

mm (1.25 inch) hoses throughout and that

way, by giving theoil the spacewe avoid

backpressure and this in turnhelpswith

cycle times.Wedo all our ownhydraulic

components inhouse anddonot buy them

in.Wehave tomeet theperformanceof the

carriers and I am100% sure thatwe can

reach the same forces andperformance

with a simpler technology just by giving

theoil the space. Toomany attachments are

heatingup and also leading to increased fuel

consumptionon carriers.”

POWER AND PRECISION

When it comes todemolishing concrete

structures or rocks, power andprecision

arewhat is required. Today’s tools provide

controlleddemolition to ensure sites remain

safe andworkprogresses swiftly.

TheTrevi BennePremiumLine consists

of four demolitionunits – theHCPremium

primarydemolition crusher, theMKPremium

multi-kit processor, theFRPremium rotating

pulveriser, and theFPremium secondary

demolitionpulveriser.

Dutch companyHydraramhas seen

increased interest in its pulveriser range.

The companydelivered twonew3 tonne,

HRP-28V360° rotatingpulverisers toDutch

demolition companyWeever Sloopwerken.

BothpulverisersweremountedonVolvo

EC300DL excavators. TheHRP-28V claims to

offer easily interchangeable teeth and a speed

valveoil valvewhich is said to facilitate rapid

work cycles. TheHydrarampulverisers are

manufactured fromdurableHardox400 steel.

Korean attachmentsmanufacturerDaemo

has introduced anew rangeof quick change

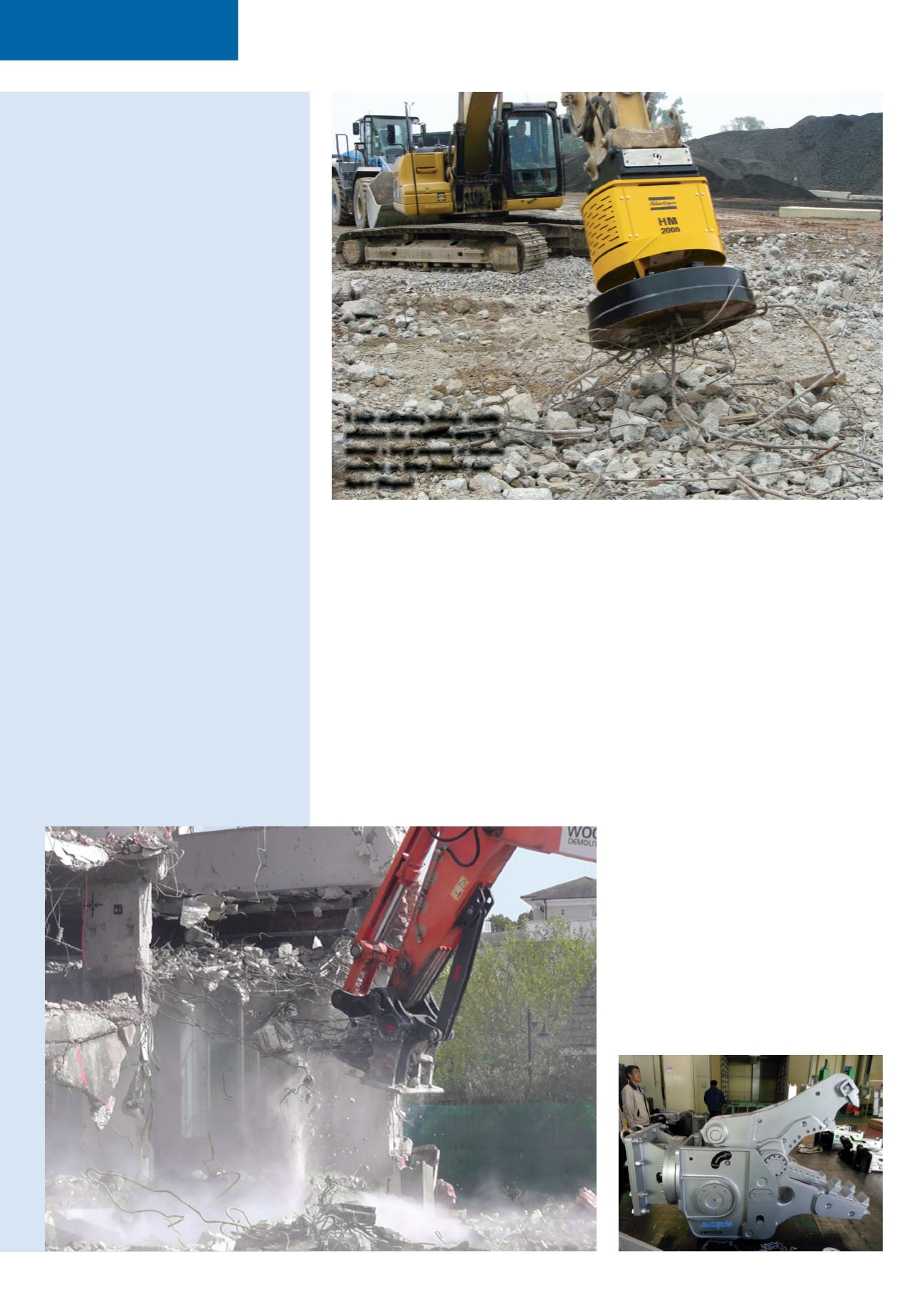

Mutley Plant Service’s specially

commissionedMPP65mounted on

Wooldridge Demolition's Hitach ZX650

in operation on site

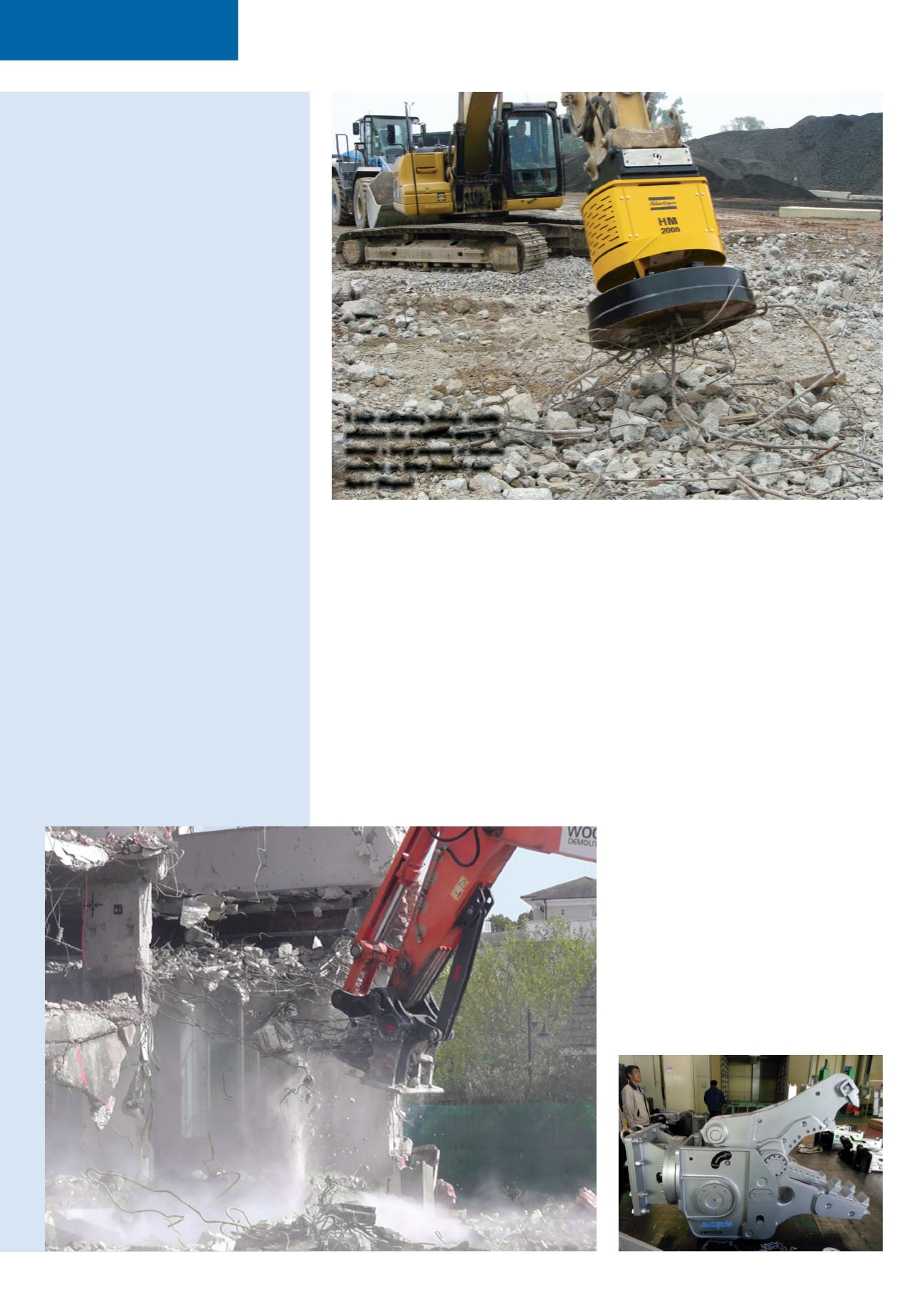

A high activating voltage rapidly

achieves themagnetic power to

attract a large amount of ferrous

material on Atlas Copco’s new

HydroMagnet

Daemo’s DMP250Q quick changemultiprocessor

workswith four interchangeable jaws

>

26