34

MAY-JUNE 2015

d

&

ri

CDE’s PeterCraven alsodoes not believe

thatwash systems are too large for use in

recycling.He said: “wehaveprovided systems

for 20 tonneper hour right up to300 tonne

per hour systems dependingon the individual

requirements of theproject. The smaller

capacities tend tobemore focusedon road

sweepings recycling.On thewaste recycling

sidewehave installed a 60 tonnes per hour

recyclingplant inStuttgart and another 300

tonnes per hour plant inScandinavia in

recentmonths, so all of theprocesseswithin

the system canbe sized according to the

individual project requirements.”

Peterwent on: “The key to success

withwaste inour experience is tobuild

the equipment for the specificproject

requirements. All of the equipmentwe

provide as part of any recyclingplant is

intended for application in this area. The

process startswithourR-Series primary

screeningunits – there are twomodels

available and these facilitate the feeding

ofwaste to theprocessingplant. The large

hopper capacities reduce the requirement for

adedicatedperson to feed theplant.”

“Material thenmoves to theM2500

Recyclingmodel – it is here thatmetals

are initially removed and aggregates are

prepared for delivery to the scrubbingphase

while the -5mmmaterial is sent to the

sandwashing stage. TheAggMaxportable

logwasher subjects thematerial to the

attrition required toproduce clean recycled

aggregateswhile also integrating a three

product sizing screen and a trash screen (for

removal of lightweights, organics andother

contaminants).”

“OurAquaCycle thickener range is then

employed to recycle approximately90%of

thewater back to thewashingplant and the

final sludge treatment stageproduces adry

cake that canbe stockpiled in aproduct bay

EU lends support

to improving waste

recycling capability

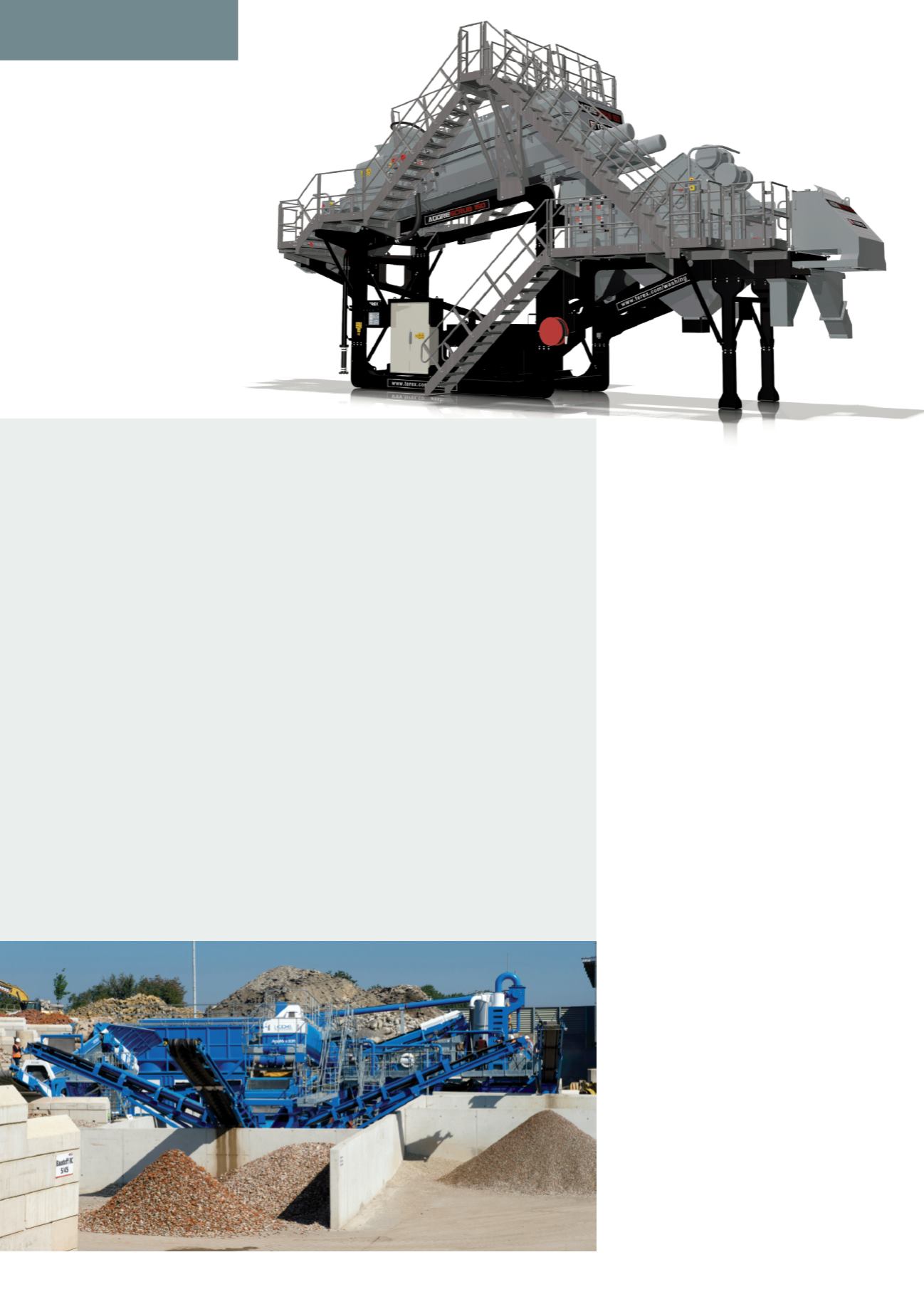

A new processing plant for construction, demolition and excavation waste has recently

been installed in Stuttgart, Germany as part of the Eco-Innovation programme from the

European Union. The plant has been installed on the site by CDE Global and includes

a series of product developments aimed at improving the quality of recycled sand and

aggregates produced from CD&E waste.

Supported by the Eco-Innovation Fund from the European Union, this new aggregate

processing system includes a new feed arrangement to the plant, enhancedmobility,

reduced plant footprint, improvedmaintenance access and developments at the sludge

management stage of the process. The project will operate under the acronym of

‘CANDY’, which stands for ‘CompAct, highly mobile, Next generation, CD&E waste

recoverY system’.

Speaking about the project, CDE regional manager for UK& Ireland, Matt Bunting

said “We have pioneered these systems in the UK over the last decade and have proven

the capability for themachines tomove recycled sand and aggregates up the value

chain. Through this partnership project with the EUwe will be able to show that systems

employed extensively in the UKmarket are themost advanced processing systems

available for construction, demolition and excavation waste.”

According toMatt, the CDE washing plants for construction, demolition and excavation

waste currently operational in the UK are divertingmore than fivemillion tonnes of this

material from landfill every year. “The product developments included within this project

will offer significant potential for both our existing customers and other waste processors

to further improve the quality of the recycled sand and aggregate products they are

producing. This will increase the commercial value of thismaterial and deliver amuch

quicker return on investment,” he said.

The installation of a CDE Global washing

plant in Stuttgart, Germany, is one result of

the EU’s Eco-Innovation programme

equipment does is carryout sizing, scrubbing

and recovery. The scrubbingprocess, by

happy coincidence, is very good at removing

lightweightmaterials (plastics, paper

etc.).Wehave theAggrescrub150 and

Aggwash (for smaller capacities) that

in addition toproduct cleaning, carry

out product segregation.With awash

system, sand and fine grit that often

makeup a sizeablepercentage of the

original feed are also separatedout

by theprocess toprovide yet another

sellableproduct.”

Iainbelieves the economics of installing

such a system certainlymakes sense.He said:

“evenwith ahigh capital system, Iwould

expect theplant topay for itself

within12months and18

wouldbe theupper end.”

AGGREGATE

WASHING

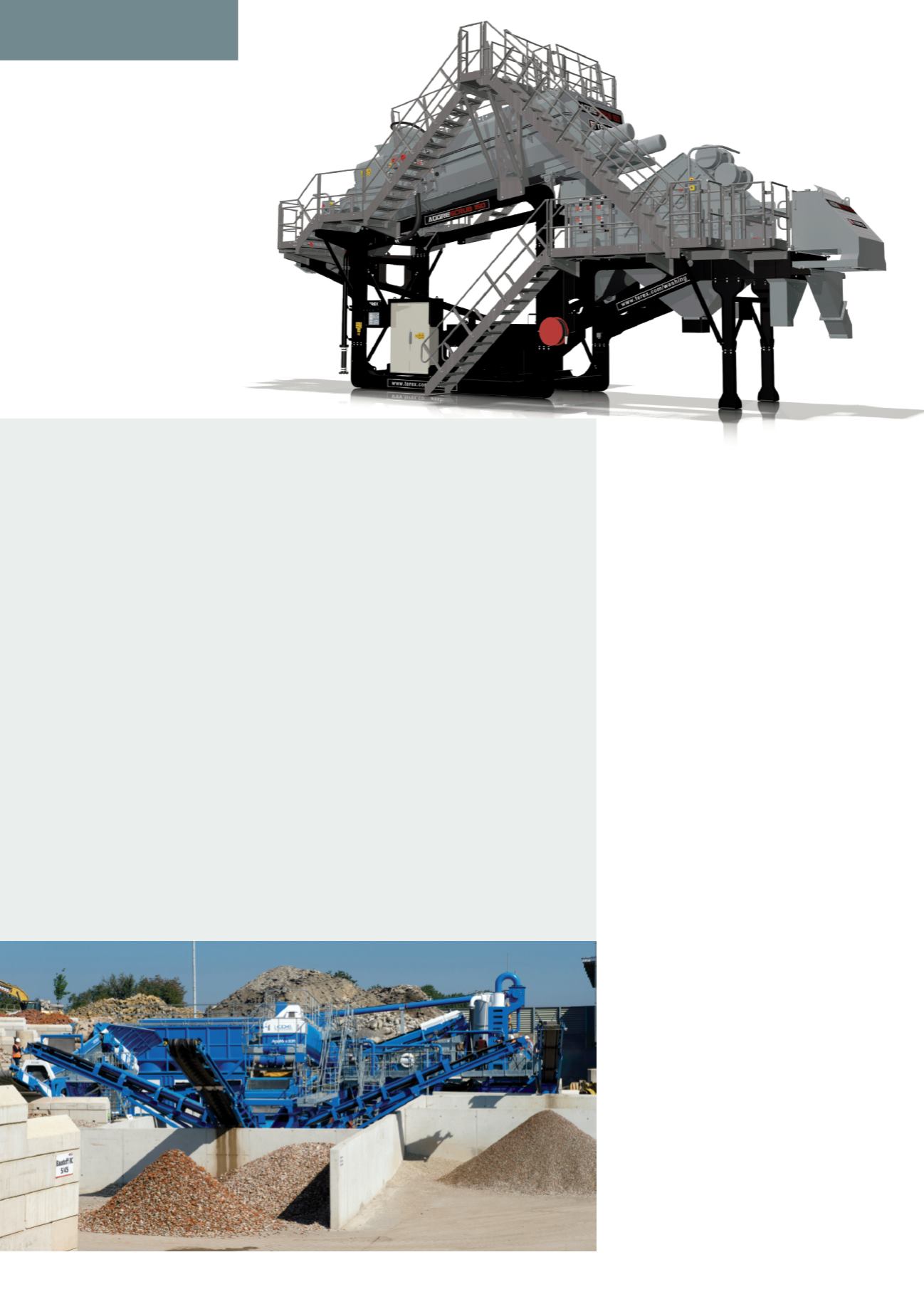

TerexWash Systems’ Aggrescrub 150, with a

maximum throughput of 150 tonnes per hour is

ideal for demolitionwaste recycling applications. It

features improvedwear characteristics, reduced

costs and the ability to scrub aggregate and float out

clays, silts, wood and plastic on a single chassis