42

MAY-JUNE 2015

d

&

ri

EQUIPMENT

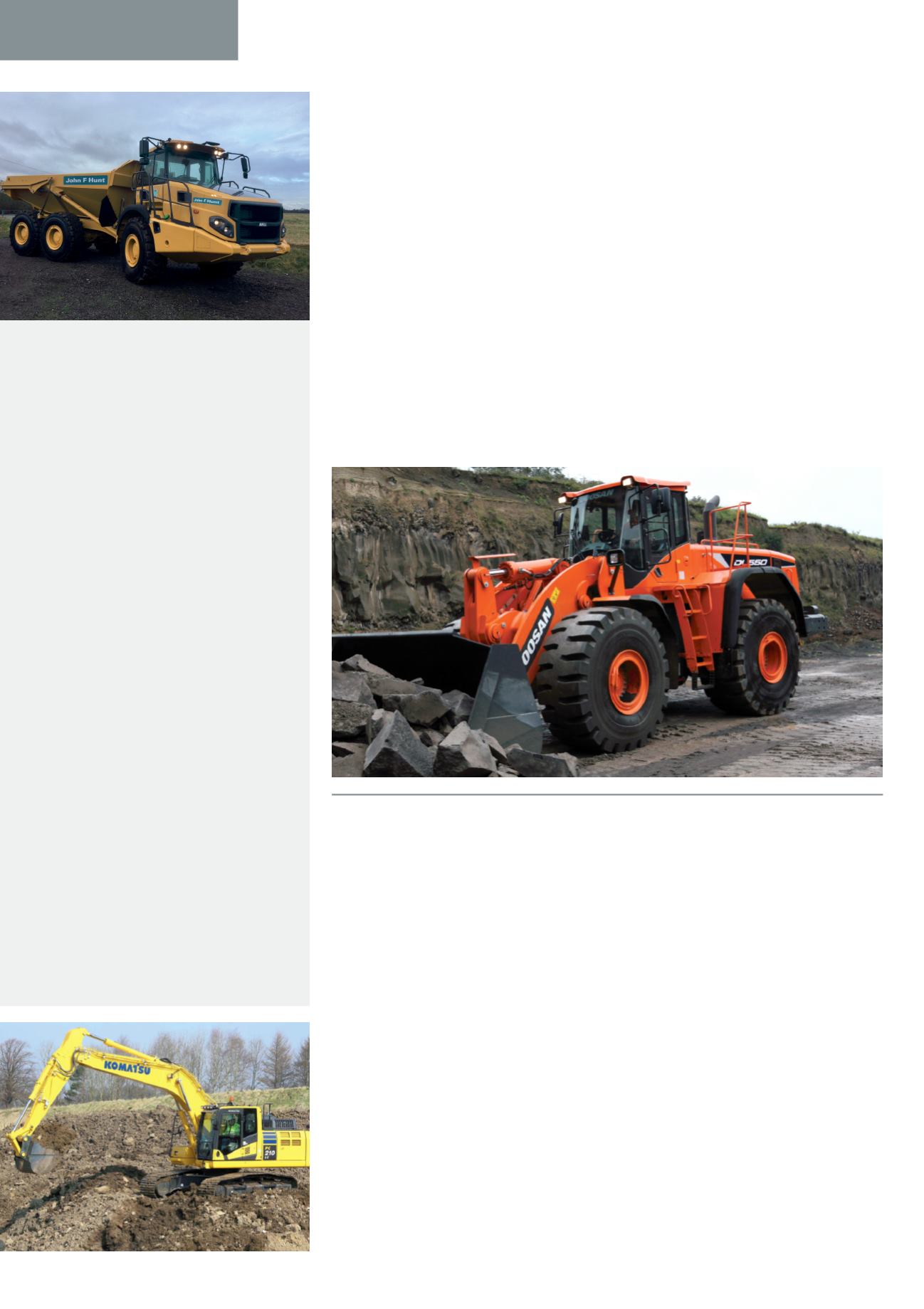

Doosan’s powerful duo

Komatsu introduces

Stage IVPC210LC-11

D

oosan Infracorehas introduced two

top-of-the-rangewheeled loaders

in itsDL-5Stage IV compliant

wheeled loaders in the shapeof the25.7

tonneDL-450-5and32.8DL550-5,with

the formerhavingaheaped capacityof 4.5

m

3

(159 ft

3

) and the latter 5.4m

3

(191 ft

3

).

Power forboth comes fromaScaniaDC13

six cylinderdiesel producing257kW (354

hp) in theDL450-5and283kW (380hp)

in the caseof theDL550-5. Providinggood

torqueat low rpm, up toa10% reduction in

fuel consumptionand excellent response, the

ScaniaDC13 enginemeets Stage IV/Tier4

Final emission regulationswithout theneed

of adiesel particulate filter (DPF) through the

useof cooled exhaust gas recirculation (EGR)

and selective catalyst reduction (SCR) after-

treatment technologies.

W

eighing frombetween22.1

to23.6 tonnesdependingon

configuration,Komatsu’s latest

generationPC210LC is said toofferup to6%

improved fuel efficiency, anupgraded cab

designand enhanced safetyand serviceability.

According to the company, the result is

maximisedproductivityand reducedoperating

costs.

Komatsu’snewEUStage IV/Tier4Final

engine integrates SCR to further reduce

NOx emissionsusing theAdBlue® additive.

Withanadvanced electronic control system

thatmanages airflow rate, fuel injection,

combustionparameters andaftertreatment

functions, it optimisesperformance, reduces

emissions andprovides advanceddiagnostic

capability.Komatsu says that its customers

Inboth, the engineAuto Idle system saves

furtheron fuel costsby lowering the idle level

from950 to750 rpm–when theoperatordoes

not giveany input to the steeringwheel, arm

andbucket formore than10 seconds (ideal

for applicationswhere there is a lot ofwaiting

time).AllDL-5 loaders featureanEngineAuto

ShutOff that shutsdown themachineafter

it hasbeen idling for a specifiedamount of

time (three to60minutes), configurableby the

operator via the control panel to further save

on fuel and reduceoperating costs.

Aswell as theScaniaDC13Stage IV engine,

theDL450-5andDL550-5 featurenew external

styling common toall of thenewDL-5Stage

IVwheel loader range, anewhigh comfort

cab, smoothand responsivehydraulics, a

ZFpowertrain, axle coolingandauxiliary

hydraulic connections.

■

The DL550-5 is the larger of two new

flagshipwheeled loaders fromDoosan

Triple Bells

Bell Equipment has supplied UK contractor

John F Hunt with three 25 tonne B25E

articulated dump trucks (ADTs) for land

remediation work on amajor contract

recently won by the latter company. They

join two D-Series ADTs that have been

in the contractor’s fleet for the last nine

years.

John Yeldham, depot manager at John

F Hunt, explained: “The Bell dump trucks

are reliable and hardworking and we’ve

experienced very little downtime. On the

rare occasions we’ve needed help, Bell has

provided a great back-up service. The Bell

B25E is the ideal size for our purposes

and we’re getting the excellent results we

anticipated.”

The new generation E-series offers

increased production payloads, lower daily

operating costs and superior ride quality,

with Bell claiming the lowest fuel cost per

tonne on themarket for itsmachines.

The smallest in the Bell ADT range, the

B25E reflects the importance of having a

high-quality, robust dump truck capable of

working within the often confined spaces

resulting from a demolition.

“It is, in part, for applications such

as these that we supply a 25-ton ADT,

so we’re delighted that John F Hunt

has recognised the advantages of

choosing a smaller machine capable of

exceeding expectations in tight working

environments,” confirmed Richard Higgott,

sales andmarketingmanager at Bell

Equipment UK.

benefit from lower fuel consumptionwith

no lossof performance.AKomatsuVariable

GeometryTurbocharger (KVGT) andan

ExhaustGasRecirculation (EGR) valve

areused forprecise temperatureandair

management and for longer component life.

ThePC210/LC-11 features aheavy-duty

undercarriageandmaintains the samehigh lift

capacityand lateral stabilityas thepriorPC210

model. Theoperator can easily select LiftMode

to raisehydraulicpressureand increase lifting

forcebyup to7%.

ThePC210/LC-11provides easier service

access tohelp reduce costlydowntime,with

guardrailsonboth sidesof theupper structure

for easier accessibility. The radiator and

hydraulicoil coolers aremounted sideby side,

making it easier tomaintainand servicewhen

required. It comes as standardwithKomatsu’s

EMMS (EquipmentManagementMonitoring

System) andKOMTRAXdatamanagement

system.

■

Komatsu’s PC210LC-11 is powered by the

company’s own Stage IV/Tier 4 Final 123 kW

(165 hp) diesel engine

UK contractor John F Hunt has opted for threeBell

ADTs as a result of amajor contract success