49

d

&

ri

MAY-JUNE 2015

IN ACTION

F

innishmining contractorE.

HartikainenOyhas comeupwith an

unusual breaker/carrier combination

to carryoutwall scalingoperations at the

Siilinjärvi phosphatemine inYara Suomi, one

of theworld’s largest producers ofmineral

fertilisers. A1,300kg (2,860 lb)Rammer 2155

hammer is beingusedmountedon a 52 tonne

Cat 345CL carrier insteadof themoreusual

carrier in the 16 to26 tonne class. In addition,

theCat is also fittedwith a lengthenedboom

that allows it to reach to26m (85.3 ft). The

faceheight at themine is 14m (46 ft), which

means that for scaling the boomneeds tobe at

least 1.5 times longer than this height.

Hartikainenhasworked as a contractor at

Siilinjärvi since 1979, employing some 200

people in the area, and currently carries out

drilling, loading andhaulingoperations of

apatite andwaste rock at themine’s twoopen-

pit quarries under a long-term contract. The

company’s fleet of 96 to140 tonpayloadhaul

trucks shifted32million tons of rock last year

alone. Excavation recordswill bebroken again

in2015, given thehigh amount of surface

waste rock as themineneeds tobe expanded

togain access todeeper lying reserves. The

ore content begins to increase at around100

m (330 ft), fromwhichpoint theproportion

ofwaste rockgraduallydecreases.

■

Scaling the

heights

Metso hits

for six

Shimizu Corporation will take delivery

of six LT 120 Lokotrack mobile jaw

crushers to assist with amajor landfill

project that it is carrying out in the

Tohoku region of Japan. The LT120's

were sold by Metso's Japanese

distributor UBEMachinery Co. Ltd., who

will also take care of the service and

parts related tasks, and will be used to

crush 6-7million tonnes of aggregates to

a tight project schedule.

The 2011 earthquake and tsunami

caused significant sinking of the ground

level in several coastal areas in the

northern part of Honshu island and

before new construction works can

begin, the level has to be raised by

several meters with aggregates.

The Lokotrack LT120 is built around

the proven C120 jaw crusher.With

its 1,200 x 870mm (4 x 2.9 ft) feed

opening, the jaw can accept even large-

sized boulders as feedmaterial. The

LT120 weighs 60 tonnes and is powered

by amodern 314 kW (421 hp) Cat C13

diesel.

The Lokotracks are being

manufactured at Metso's facility in

Tampere, Finland, and will be delivered to

Japan in spring 2015. At the sites in the

Tohoku region, they will be operated as

single units producing 0-200mm

(0-8 inch) aggregates for landfill.

TheRammer 2155 iswielded by a Cat 345 CL

with an extended boom that reaches 26m

Electric sorting

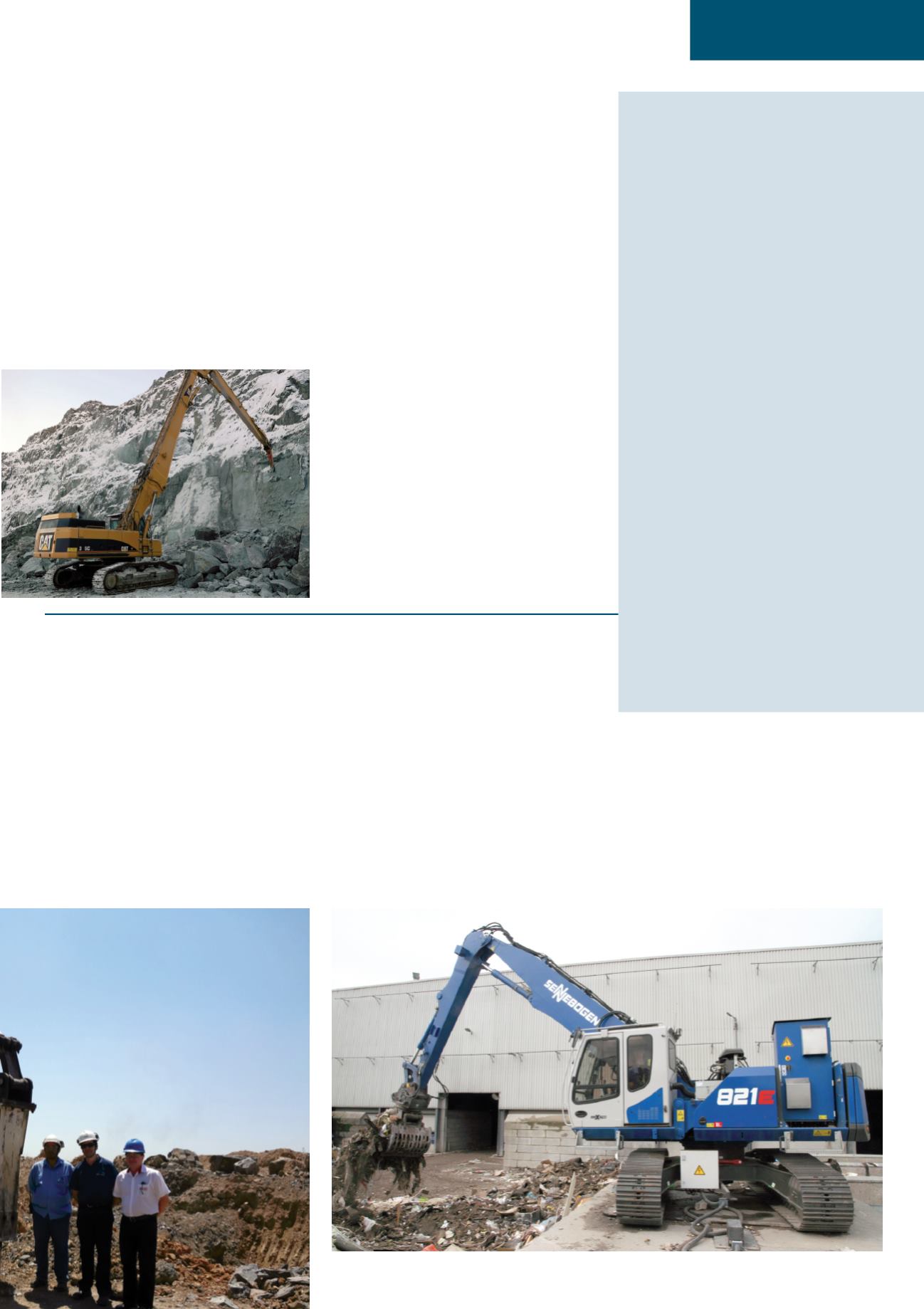

An electricallypoweredSennebogen821

Electromaterial handler, deliveredby

dealerKuikenN.V., is providinghandlingof

construction anddemolitionwaste at Baetsen

Recycling’s facility inSon, theNetherlands,

where the companyoperates twomodern

sortingplants on an8.5hectare site.

At theEkkersrijt facility inSon, thewaste

delivered to the site is sorted into21partial

flows, with the 821Electropositioned at the

start of theprocess chainwhere it carries

out thepre-sorting into eight different

graded categories. Themachine is positioned

centrallyon a ramp, allowing the operator

a clear viewof the area and the 11m (36 ft)

reachprovidedby the 821provides safe access

to all sortingboxes. Themachine is inuse 10

hours aday and is therefore capableof sorting

120,000 tonnes ofmaterial per year.

According to facilitymanagerMarc

Peperkamp, the 821Electroprovides a saving

of up to50% inoperating and energy costs

over the standard excavator it replaced,

alongwith lowermaintenance costs and less

downtime becauseno refueling is required.

Thanks to its robust crawler undercarriage,

A Sennebogen 821 Electro carries out

pre-sorting duties at Baetsen’s Son

recycling facility in theNetherlands

themachine is not only extremely stablebut

alsomoves easily along the sortingboxes.

It is not just the specialmaterial handling

characteristics providedby itsULM stick and

sortinggrab, but also the extended reach that

are additional advantageswhen compared

with thepredecessormachine. Supplemental

LEDheadlights andmultiple surrounding

cameras offer an ideal all-round view, even in

badweather.

■