48

MAY-JUNE 2015

d

&

ri

IN ACTION

T

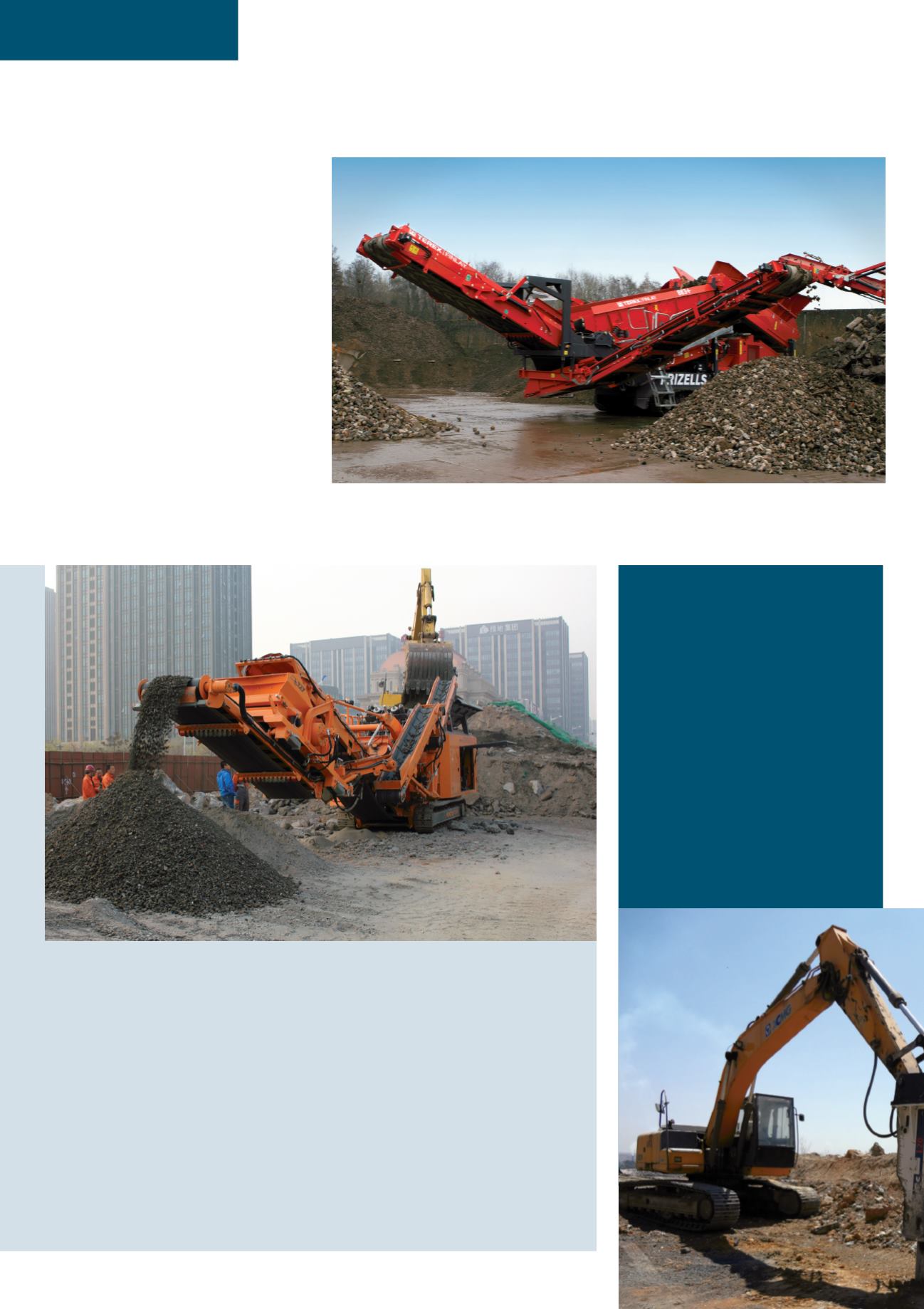

WFrizell (Haulage andPlantHire)

has takendeliveryof aTerexFinlay

883+ tracked screen that joins aTerex

Finlay J-1170 jaw crusher supplied sixmonths

ago, withbothmachines suppliedbyFinlay

Central. Both are currentlyoperating at the

company’s new recycling centre established

inStoke-on-Trent,UK, althoughboth are

availableonhire for contract crushing and

screening.

Thematerial that is brought to the site is

fed through the J-1170 and into the 883+ to

produceMOT, pipebedding, filtermedia and

topsoil. With increased site efficiency gained

frombothmachinesworkinghand inhand,

95%of thematerial brought toFrizell's facility

is recycled andprocessed at amuchgreater

speed.

TheTerexFinlay883+has the capacity to

process at a rateof up to500 tonnes per hour

andhas beendesigned towork either on its

ownor after aprimary crusher. Theplant

features amodular configuration screenbox

with a 4.9x1.6m (16x5 ft) topdeck and

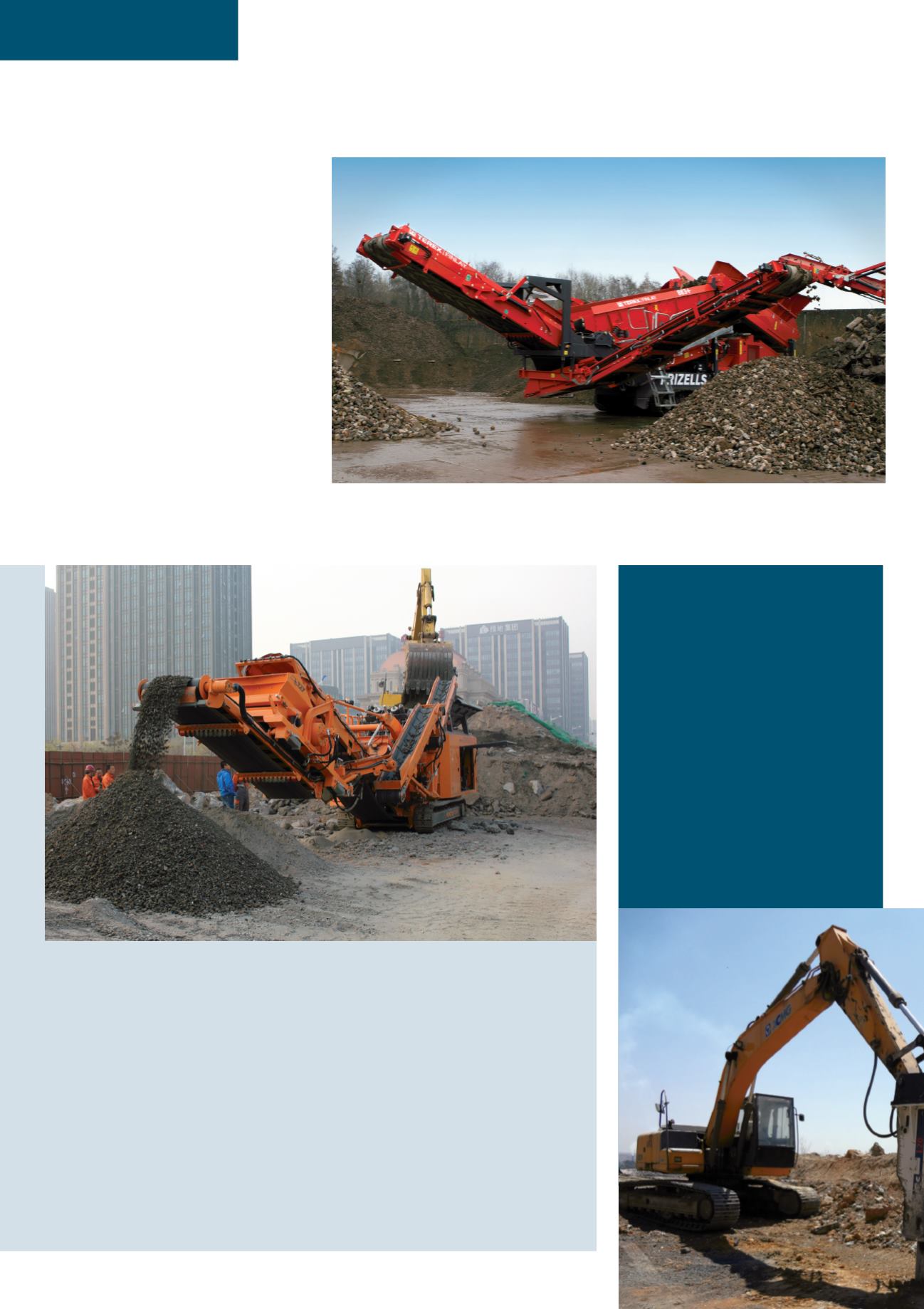

Beijing first for Rockster

In what is claimed as a first, a Rockster Recycler R700S tracked impact crusher was

used by specialist contractor Beijing Yu Long Environment Protection during the renewal

of a road in the Chinese capital of Beijing. Likemany of itsWestern counterparts, the

local government bodies have laid down strict requirements concerning the use of mobile

crushers within the city boundaries, and this is said to be the first time that recycled

asphalt and concrete were crushed directly on a site and immediately reused in the city.

The R700S produced a constant output in excess of 100 tonnes per hour to a size of

0/32mm and also showed low fuel consumption. The R700Swas also fitted with dust

suppression on themain belt, resulting inminimal emissions of either dust or exhaust

gases during themachine’s operation.

MrWang, the project manager at Beijing City Road and Bridge Construction Group,

said: "It is very important for us to recycle construction waste so we can protect the

environment and save natural resources." Estimates indicate that 40million tonnes of

demolition waste is generated within Beijing every year, with some 90% of this being

reusable, suggesting amajor opportunity for efficient recycling operations.

Increasing capacity

The new Terex Finlay 883+ joins a J-1170 crusher at

TW Frizell’s new Stoke-on-Trent recycling centre

A 1,340 kg (2,948 lb) Sandvik Bretec L20 breaker,

supplied through dealer Rock Brit, is being used

by Brazilian cement producer Brennand Cimentos

S/A, mounted on a XCMG XE210 excavator, in a

secondary breaking role to deal with boulders

that are too large to bemoved or crushed,

resulting in improved operational efficiency. The

silenced breaker isworking at the company’s

facility at Sete Lagoas, which producesmore

than amillion tonnes of Portland cement annually.

“We trialed a competitive breaker but it simply

could not break these boulders. In fact, when

the Bretec L20was delivered by Rock Brit,

we already had a big square boulder that the

previous hammer had failed to break,” commented

mining coordinator Paulo Pereira, who further

added; “The Bretec breaker made an immediate

impact. Sincewe installed the (Bretec) hydraulic

hammer it hasworkedwell. Productivity has been

very good!”

TheR700S impact crusher atwork processing 5,500

tonnes of asphalt and concrete inBeijing

bottomdeck screen, withoptional features to

permit tines or cassette frames to enablemesh

fitting. Trackmounted tomaximise onsite

portability and ease of operation, it alsohas

threehydraulic folding stockpilers toprovide

increasedproduction.

■