45

d

&

ri

MAY-JUNE 2015

EQUIPMENT

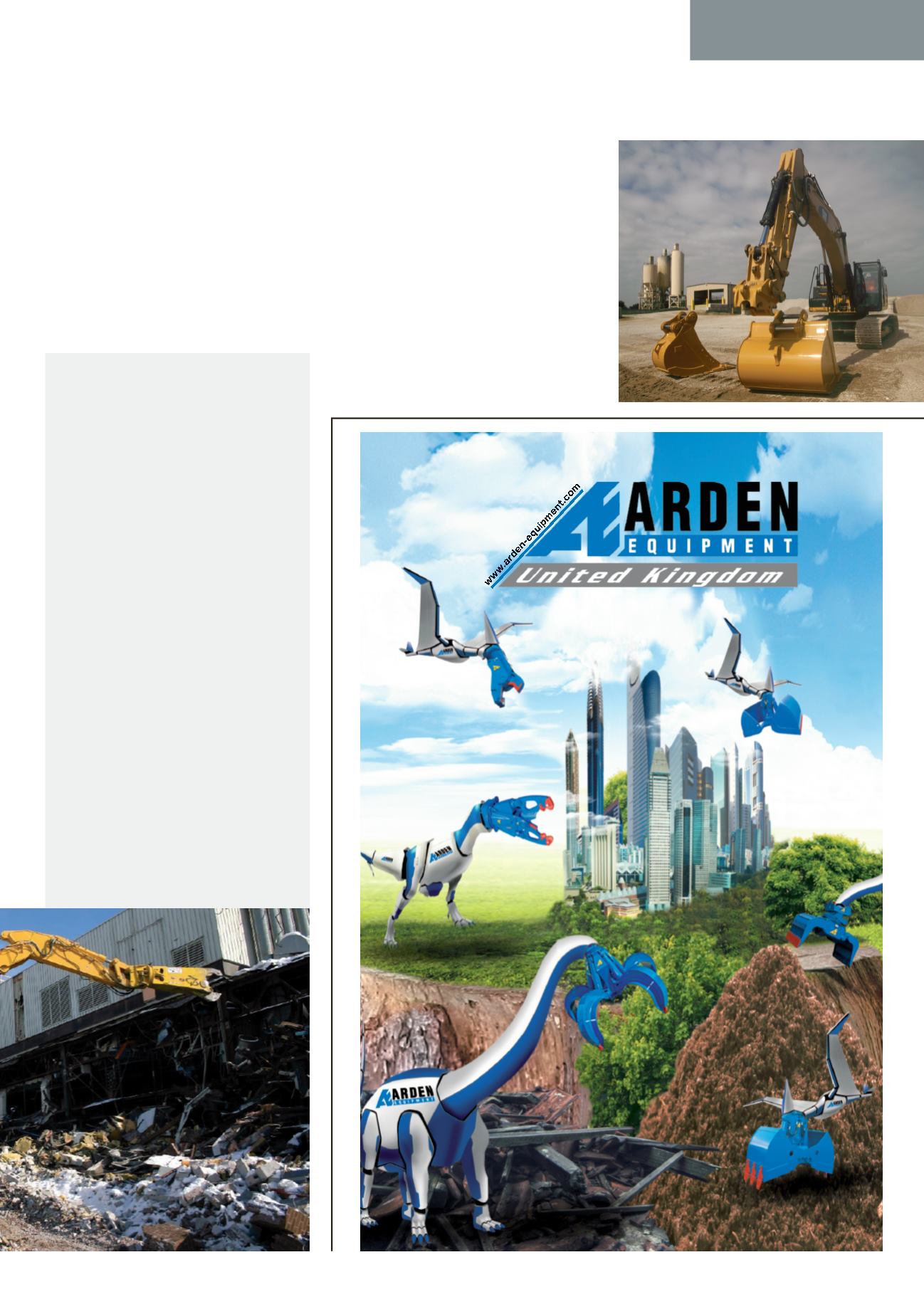

Cat coupler grabs attention

C

at has introduced anewpingrabber

coupler that it says has beendesigned

for safety andperformance. It features

apowerful, two-stage locking system that

ensureswork tool engagement andprovides

both an audio and visual verificationof

proper attachment.Once engaged, the

internalmechanism then combineswith

continual hydraulic force from themachine

and actual digging forces tokeep thework

tool secure.

It features awedge-lock system for

primarypin retention, aswell as apositive

secondary latch. The systemmaintains

constant hydraulicpressureon thewedge;

the coupler frame, rather than the activating

cylinder, absorbsmost of the forces involved

tohelp ensure long-termdurability. In

compliancewithnew safety regulations, the

couplermaintains tool position in the event of

hydraulicpressure loss.

Thenew coupler is available for excavator

models 311 through349 (D, E, andFSeries)

and is compatiblewithCatwork tools and

most competitivebuckets. In addition,most

FSeriesmodels have factory-installed

auxiliaryhydraulic systems ready tooperate

the coupler.

■

Cat’s new pin grabber

coupler is available for

its 311 through to 349

D E and F excavator

models

Kobelco first

for Priestly

Ontario, Canada, based Priestly Demolition

Inc has become the first customer

inNorth America for Kobelco’s 112

tonne, 40m (132 ft) reach SK1000D

demolition excavator, which was supplied

through dealer Robert Green Equipment

Sales. Ryan Priestly, president/owner

and AndrewKelly, equipment manager/

mastermechanic of PDI first saw the

SK1000 at ConExpo inMarch 2014. Ken

Folden, Canadian service representative

for Kobelco ConstructionMachinery USA,

demonstrated themachine’s features to

both. “Ken emphasised themachine’s

impressive ability of being assembled,

moved, and up-and-running within hours.

He sold us on its capabilities right there at

the show,” said Ryan. “Two weeks later,

Bob Green fromRobert Green Equipment

visited our office. I told him how impressed

I was with the SK1000 and that I wanted

to buy it from him.”

Themachine was transported from

Las Vegas, where it was being stored,

to Ontario in a process that required

seven separate loads and was put

straight to work on the demolition of a

former General Motors assembly plant in

Oshawa, Ontario.

om

Tools

to make it possible...