44

MAY-JUNE 2015

d

&

ri

EQUIPMENT

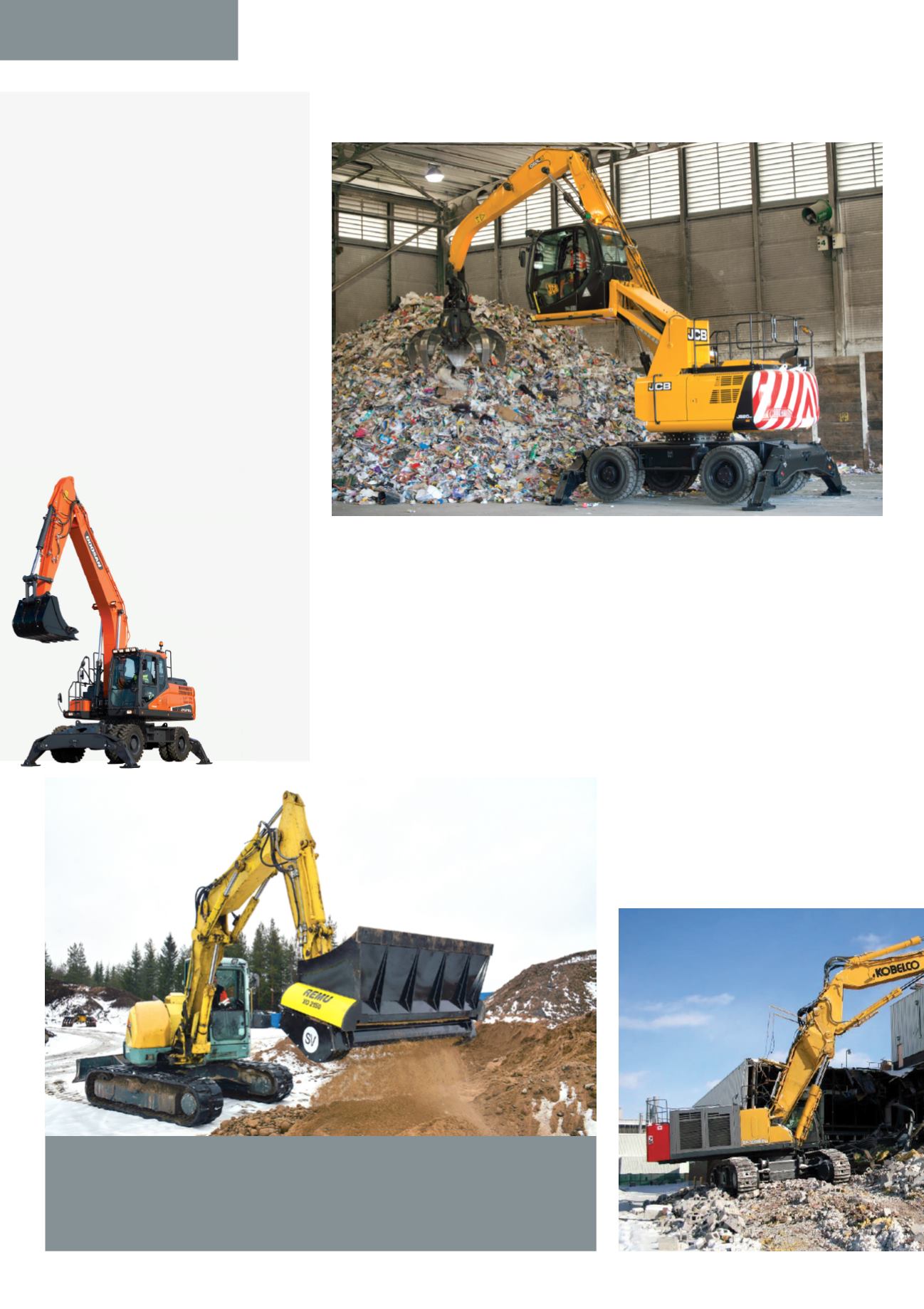

JCB fleet for Norse

Two JS20MHmachines are just part of the new JCB fleet purchased byNEWS

N

orfolk,UK, basedNorse

EnvironmentalWaste Services

(NEWS) has invested in anew fleet

of JCBWastemastermachines, suppliedby

local dealerWatling JCB, tohelp it deal with

increaseddemand for its services. Theorder

consistedof two JS20MHmaterial handlers,

three 437HTwheeled loaders, a 427HT loader

and two541-70 telescopichandlers, all of

which are coveredby a five year repair and

maintenance agreement.

NEWS, adivisionof theNorseGroup,

operates three transfer stationswithin the

country and alsomanages two third-party

stations. All feedNEWS’ ownmaterial

recovery facility that recentlybenefitted from

a £10million (US$14.8million) investment

tomeet growingdemand, with the company

processing90,000 tonnes of dry recyclable

material each year.

The availabilityofwaste industry-specific

models played a crucial role in thedecision to

gowith JCB. Transfer stationmanager John

Tillbrook said: “Theydo a full range to suit

our business from fork trucks, telehandlers,

shovels andmaterial handlers and everything

is available inWastemaster specification

todealwith theworking environment in

wastehandling.Wehaven’t got to try and

add spec afterwards.Whenwe looked at the

specification at tender stagewe sat down

and thoughtwhat dowe reallyneed and the

Wastemaster spec gaveus everythingwe

wantedon all of the kit available.”

■

Doosan sets

the style

Doosan has introduced the 20.9 tonne

DX210W-5 Stage IV-complaint wheeled

excavator that the company claims offers

enhanced comfort and controllability as

well as improved fuel efficiency, uptime and

return on investment. Themachine comes

as standard with Doosan’s wireless fleet

monitoring system, CoreTMS.

Power comes from a 6 cylinder

turbocharged Doosan DL06Pwater cooled

diesel delivering 141.2 kW (189 hp), 17%

more engine power than was available on

the previous generationmachine. Doosan

said that other engine enhancements

reduce fuel consumption by 10%.

As well as the 17% increase in engine

power, the DX210W-5 has 14%more

engine torque. The new Posicon hydraulic

system also offers a 3% increase in

hydraulic capacity, which translates

into an 8% improvement in the

bucket force and 6%more arm

force. The 900 kg (1,980

lb) weight increase and the

greatermachine width result

in front lifting capacities

being increased to 8%

(attachment down/up),

while the over the

side capacities

have increased

by 12 to 15%

(attachment

down/up).

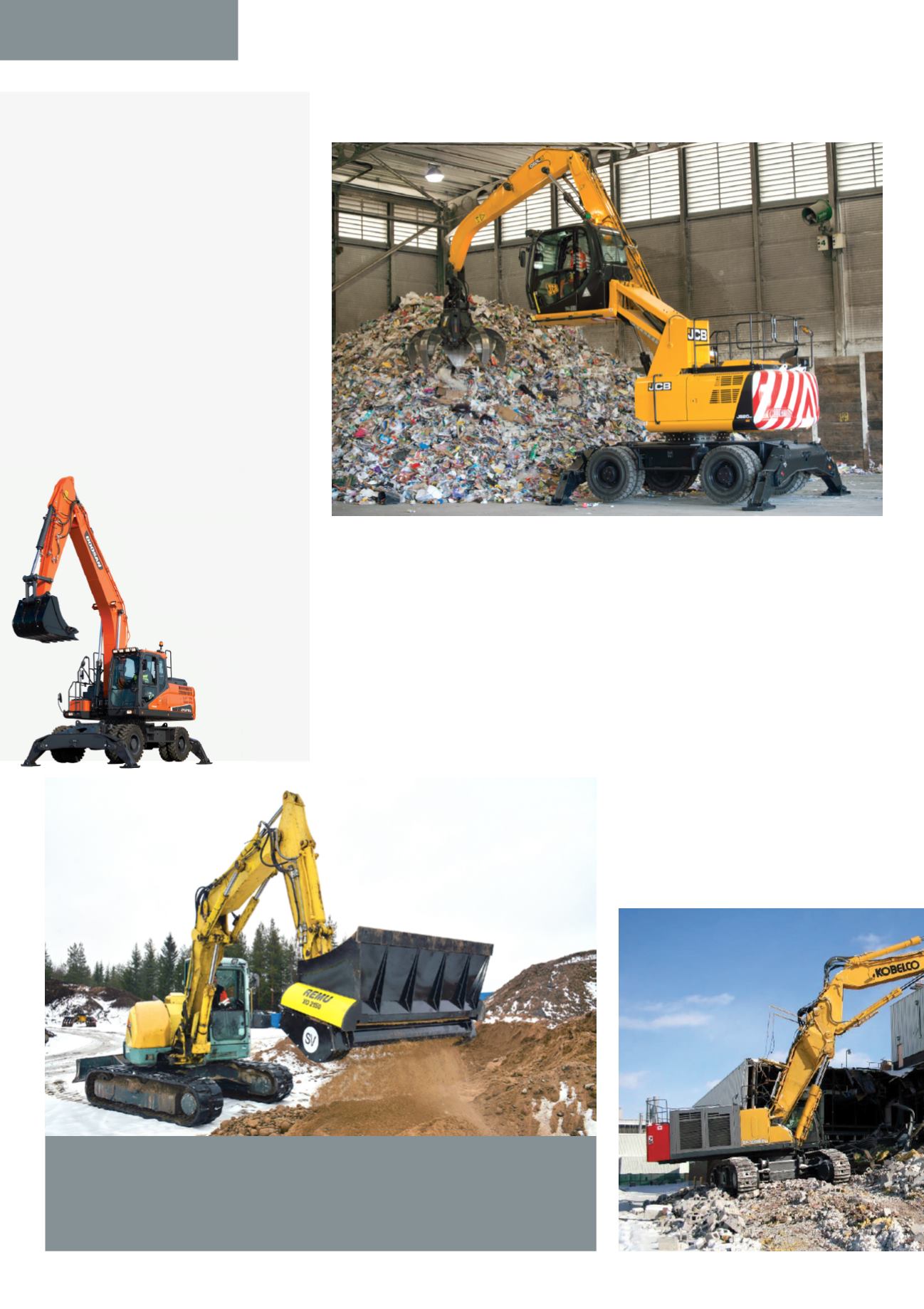

Remu is set to use the Plantworx show in the UK to show off a new concept in screening buckets in

conjunctionwith UK dealerWorsley Plant when it introduces the new Crossover screening bucket. This

is a concept that consists of a bucket frame that can be connected to different workmodules to allow

fast changes for different jobs. Threemodules are currently available – the blade screenmodule (SB) for

screening topsoil, the screener crusher (SC) for grinding lumpymaterial and the vibrating screen (SV) for

separating sand or other loose and drymaterials, and shakingwaste and dirt from recyclablematerial