39

d

&

ri

MAY-JUNE 2015

SITE REPORT

of oil-filled transmission cableswith

polyethylene replacements –work that has to

be completed throughout Belgiumby2020.

TheZeebruggeproject included the

demolitionof twoheavily reinforced storage

tanks, eachofwhichonce contained5million

litres (1.1milliongallons) of kerosene. Each

was buriedunder 1m (3.3 ft) of sand, andhad

a 60 cm (2 ft) thick reinforced concrete top

plate and slightly thinner reinforced concrete

sidewalls.

In addition to the tanks, therewere two

heavily armoured reinforced concretebunkers

that housed thenecessaryhighpressure

pumps that transferred the fuel through the

pipelines, and anumber of other buildings

around the site, includingguardhouses and

associated residential structures. In addition,

all theunderground cables andpipes had to

be found anddugup, and at the endof the

demolitionphase, the sitehad tobe totally

clean and exactly level.

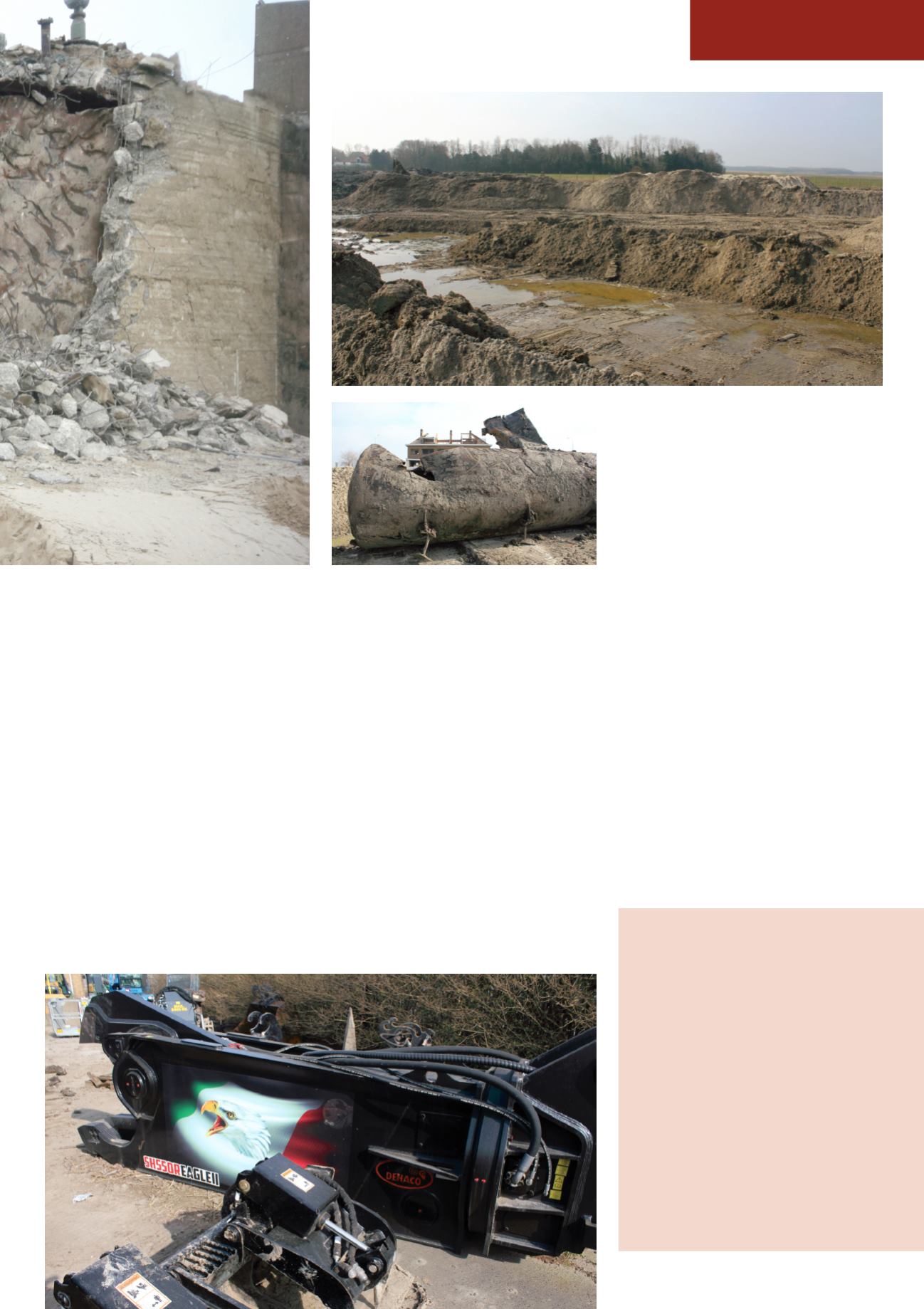

In a first for the region, Princen recently

tookdeliveryof the firstVolvoEC480D

HRhigh reachdemolition excavator tobe

deployed in theBenelux countries along

with associatedDehaco attachments. It is

equippedwith a short, straight boom and arm

configuration. Thiswas deployed to the site to

dealwith thephysical demolitionof themore

robust structures.

According tooperator andownerWesley:

“With the short boom, I have apinheight of

14m andbecauseof themachine’sweight of

63 tonnes, additional counterweight and4

m trackwidth, I canworkwith a 4.8 tonne

crusherwith excellent stability,”Wesley

added. “I also like thehydraulically variable

undercarriage andVolvo’s hydraulic joint,

whichmakes tool changes quick and easy.”

Ground conditions had an impact on

Princen’s selectionof theother earthmoving

equipment on the site. The companyopted

for trackeddumpers insteadof articulated

haulers tomovematerials during earthmoving

operations, since inwet conditions the

ground surface veryquickly could turn into a

quagmire because of its claynature, a fact that

was not helpedby the fact that the ground

surface inmanyplaceswas very close to, if not

at, the groundwater level.

Leveling the sloping sitewithheight

differences of up to3m (10 ft) involved the

recycling of some 12,000 tonnes of concrete

and50,000m

3

of earth.

Given the clay conditions andhighwater

table, the ground surfacehad tobeprepared

for the constructionof thenew substation,

whichwill require covering the entire site

with sand0.7mdeep. The sandused for

thiswas recovered from the site and stored

until theworkbegan - in total, 95%of the

materials used to level the sitewas recycled.

Theproject began inmid-December 2015 and

thedemolition and the clean-upphasewas

completedon schedule.

■

Reaching

high

When fitted with its 27m (88.6 ft) high

reach boom, the Volvo EC480DHR can

carry an attachment up to three tonnes.

Safety features include boom-and-arm

holding valves, forward and rear view

cameras, as well as roof and front screen

protection. It also has a Total Moment

Indicator that warns the operator if the

machine approaches themaximum safe

working load. For enhanced visibility and

reduced operator fatigue when working at

high reach, the tilting cab pivots up to 30°.

When not required for high reach work,

themachine’s boom can be switched from

its demolition equipment to a standard dig

boom and arm in just 1.5 hours.

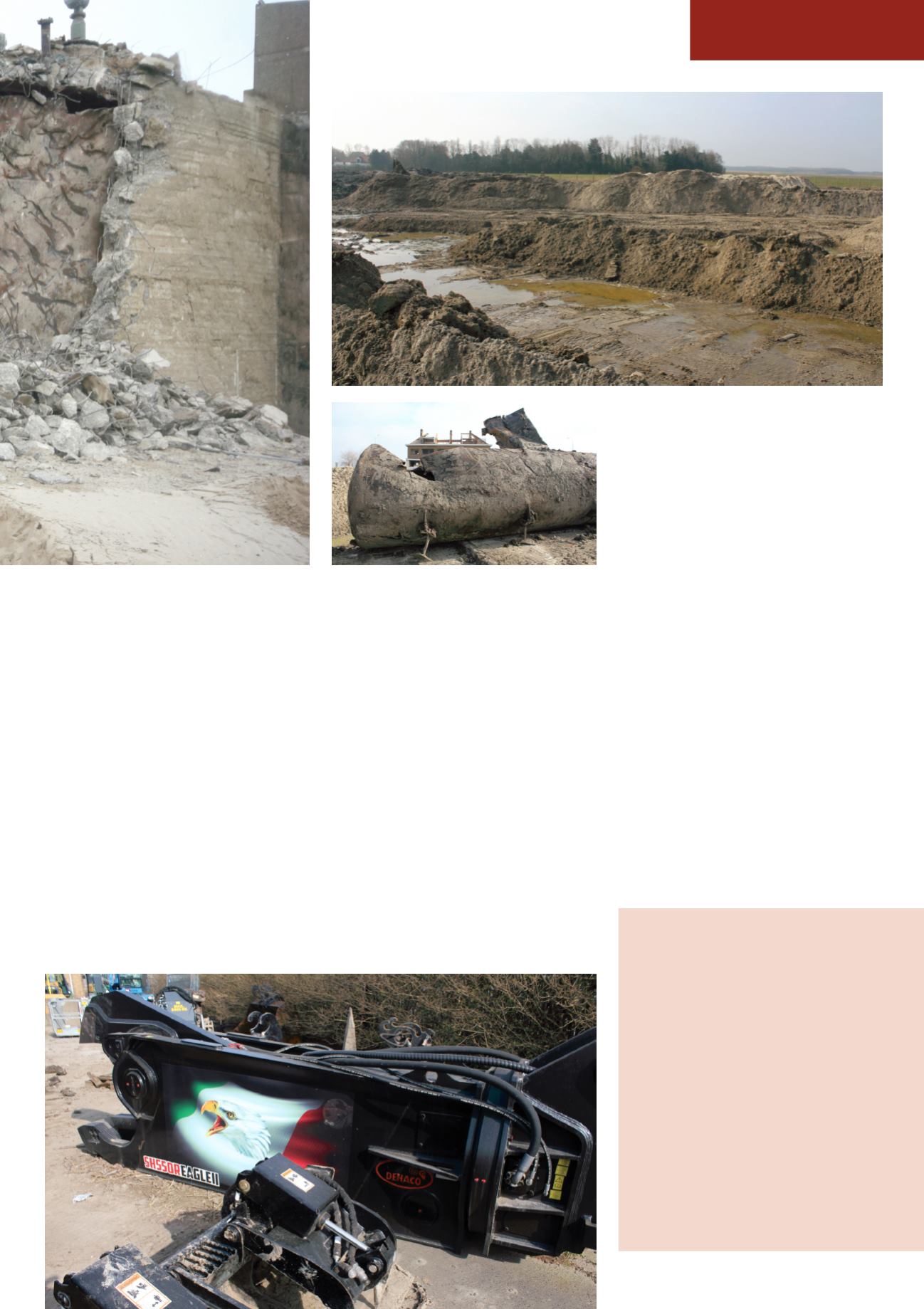

The one remaining fuel storage tank on the site

at the time of D&Ri’s visitwas heavily protected

by thick reinforced concretewalls and alsowith

a thick covering of sand, which Princen had to

remove before starting the demolition

Once cleaned and remediated, the ground

surface is very close to thewater table so a 0.7

m layer of sand is being laid across the entire

site prior to construction beginning.

One of two oil tanks thatwere originally

buried under the surface for protection and

which proved a challenge to remove

In addition to the 4.8 tonne Dehaco , Princen also acquired a newDehaco SH550R shear for the new

Volvo to allow it to process themetals from the site